Maintenance

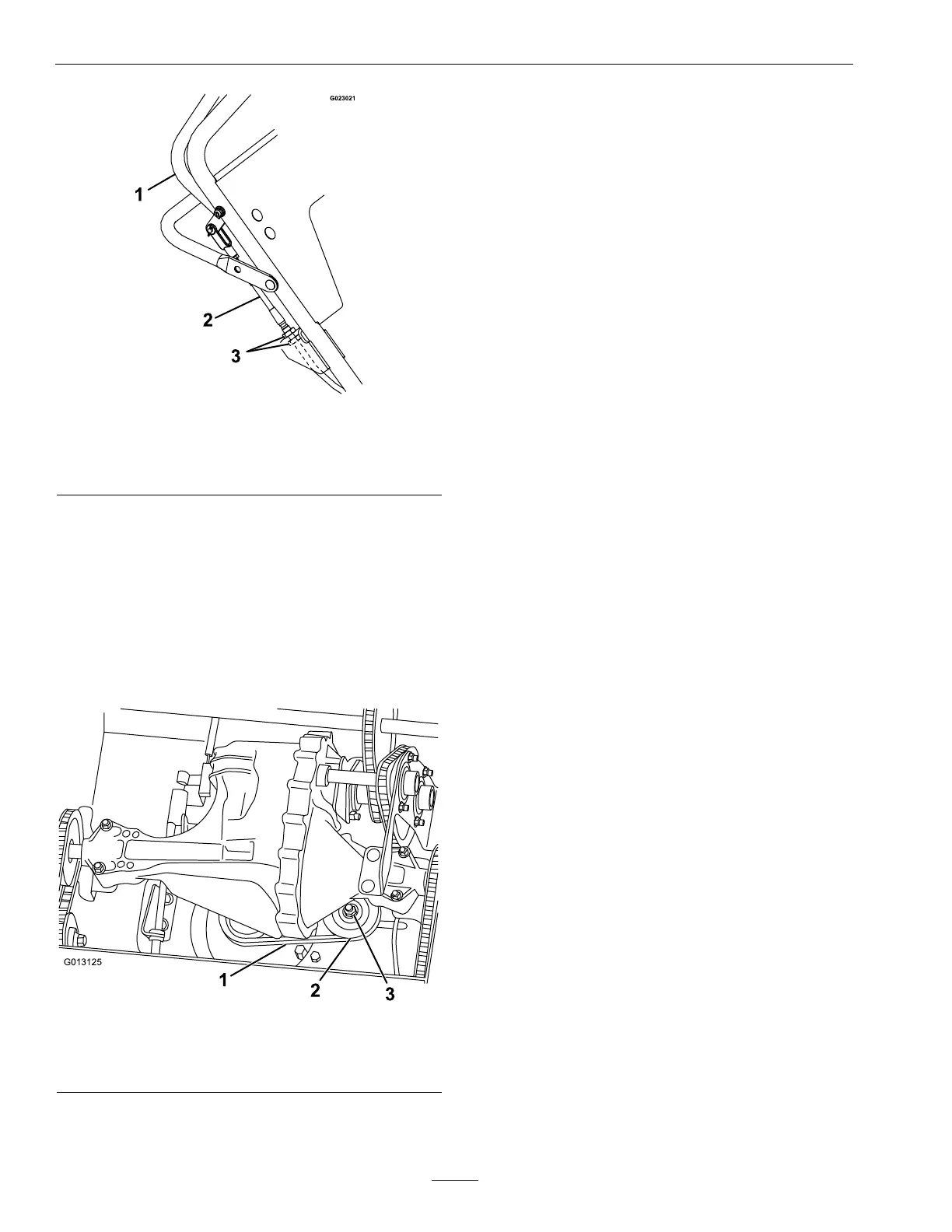

Figure12

1.Self-propeldrivebail3.T op/Bottomadjustment

nuts

2.Cable

AdjustingtheTransmission

DriveBeltTension

1.Stopengine,waitforallmovingpartstostop.

2.Disconnectthewirefromthesparkplug.

3.Loosenthenutsecuringtheidlerpulley(see

Figure13).

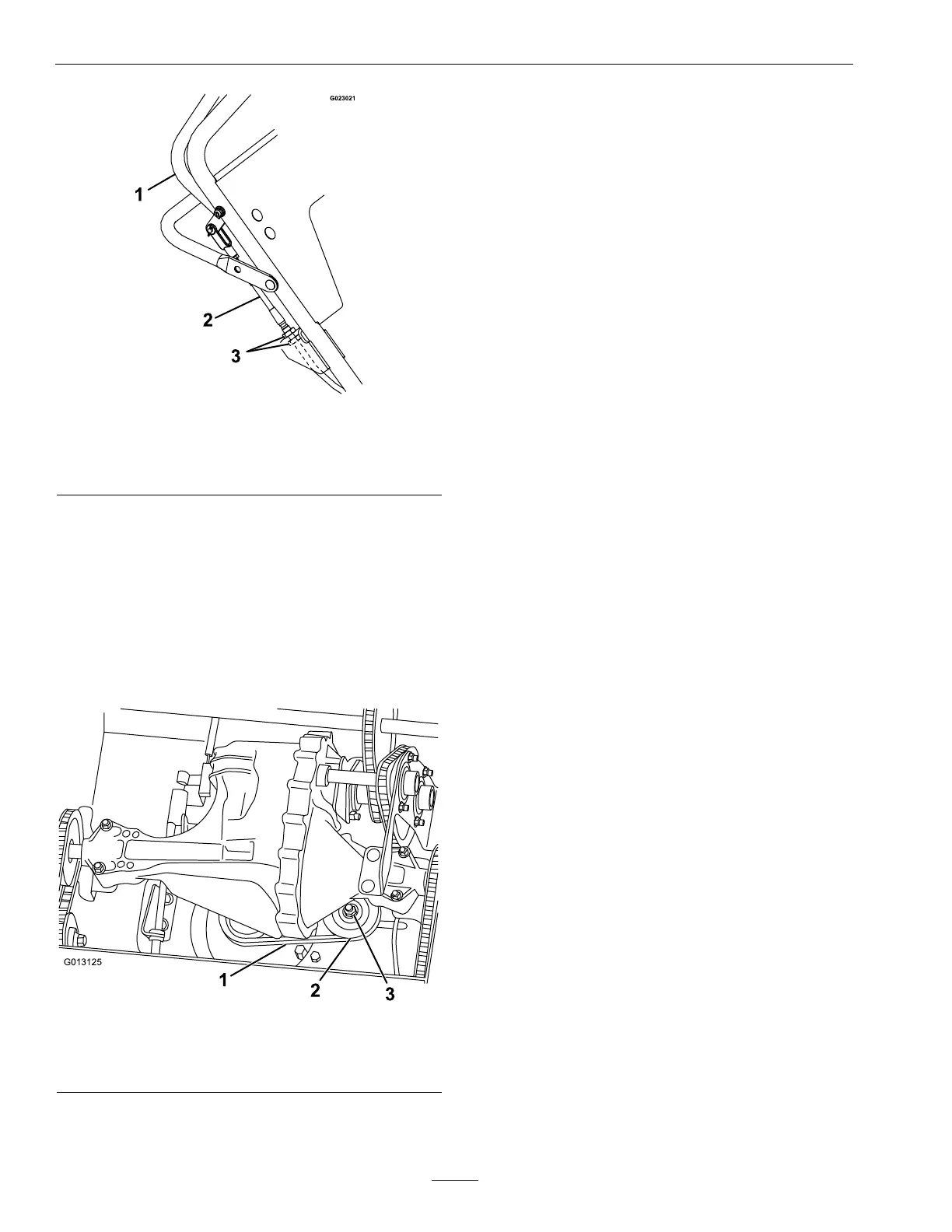

Figure13

1.Pumpdrivebelt3.Idlerpulleynut

2.Idlerpulley

4.Pushtheidlerpulleytothelefttotightenthebelt.

5.Tightentheidlerpulleynutandtorqueitto30

ft-lb(41N-m).

6.Pushonaspanofthedrivebeltwith20lb(9kg)

offorce,thebeltshouldnotexmorethan1/8

inch(3mm).

AdjustingtheTineDrive

Chain

1.Stopengine,waitforallmovingpartstostop.

2.Disconnectthewirefromthesparkplug.

3.Liftthefrontoftheunitandsupportusingjack

standsorequivalentsupport.

4.Checkthechainsonbothsidesoftheunitfor

propertension.Thechainsshouldbeableto

moveupanddown1/4inch(6mm)maximum.

5.Adjusttheidlersprocket.

6.Recheckthechaintensionandtightentheidler

bolt.

AdjustingtheCoringDepth

Acoringdepthof21/2inches(63.5mm)is

recommended,butyoucanchangethedepthas

follows:

1.Stopengine,waitforallmovingpartstostop.

2.Disconnectthewirefromthesparkplug.

3.Loosenthenutssecuringthewheelstoponthe

rightsideofthemachine(seeFigure14).

26

Loading...

Loading...