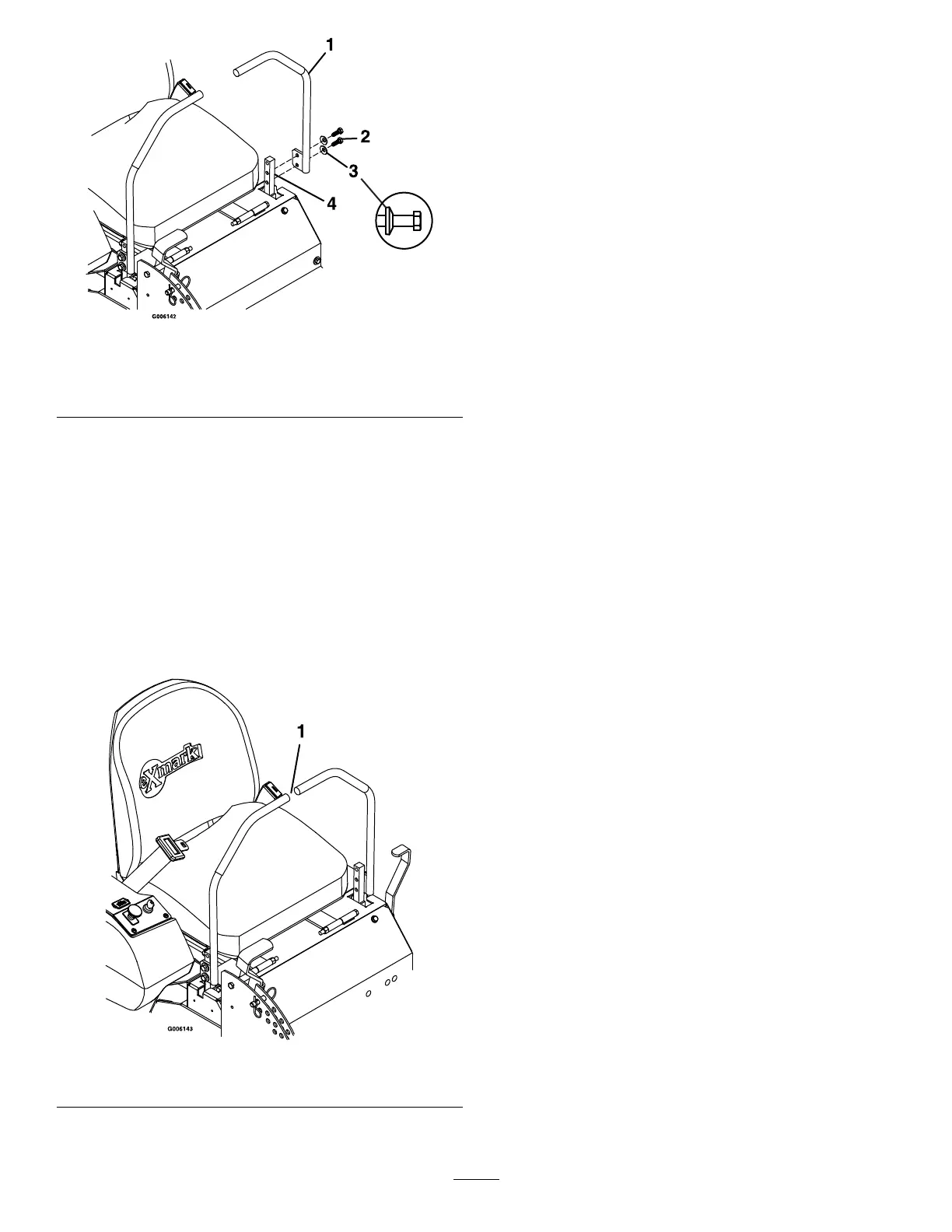

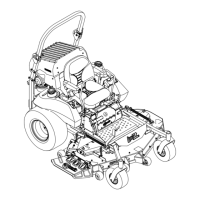

Figure6

1.Motioncontrollever

3.Springdiscwashers(cone

towardsbolthead)

2.3/8x1inchbolts4.Controlarmshaft

6.Aligntheleversfront/rearposition.Withthelevers

intheneutralposition,loosenthehardwareand

adjusttheleversslidingand/ortiltingthelever(s)

forwardorbackwarduntilproperlyalignedand

tightenhardware(Figure7).

7.Iftheendsofthelevershitagainsteachother,

whileinthedriveposition(leversrotatedinasfaras

possible),makeadjustmentsbymovingthelevers

outwardstotheneutrallockpositionandcarefully

bendingthemoutward.Movethembacktothedrive

positionandcheckforclearance.Repeatifnecessary.

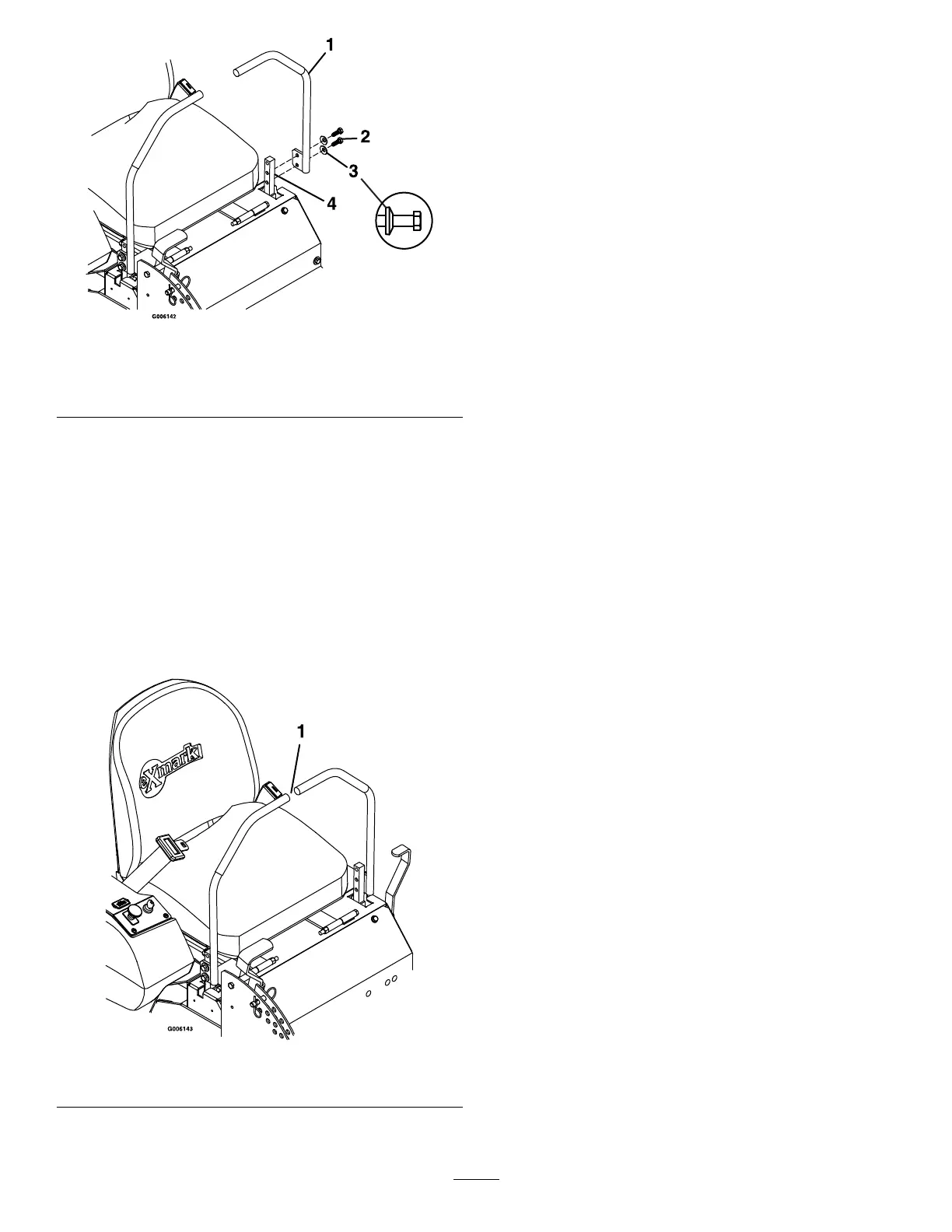

Figure7

1.Leversinalignment

PositioningtheDischargeChute

Loosentwo5/16inchnylocnutsattachingdischarge

chute.Lowerthedischargechuteintoposition.

Retightennylocnutsuntilchuteissnugbutcanpivot

freely.

ServicingtheEngine

RefertoEngineOwner’sManual.

ServicingtheHydraulicOil

Themachineisshippedwithhydraulicoilinthe

reservoir.

1.Runthemachineforapproximately15minutesto

allowanyextraairtopurgeoutofthehydraulic

system.

2.Checkhydraulicreservoirandifnecessaryllthe

reservoirtotheappropriatelevelwithMobil1

15W-50syntheticmotoroil.

3.Replacehydraulicreservoircapandtightenuntil

snug.Donotovertighten.

Note:Thebafeislabeled“HOT”and“COLD”.

Theoillevelvarieswiththetemperatureoftheoil.

The“HOT”levelshowsthelevelofoilwhenitisat

225°F(107°C).The“COLD”levelshowsthelevelof

theoilwhenitisat75°F(24°C).Filltotheappropriate

leveldependinguponthetemperatureoftheoil.For

example:Iftheoilisabout150°F(65°C).Filltohalfway

betweenthe“HOT”and“COLD”levels.Iftheoilisat

roomtemperature(about75°F(24°C)),llonlytothe

“COLD”level.

FillingOuttheWarranty

RegistrationForm

Filloutwarrantyregistrationformandplacekeysinto

literaturepack.

6

Loading...

Loading...