www.fastech.co.kr

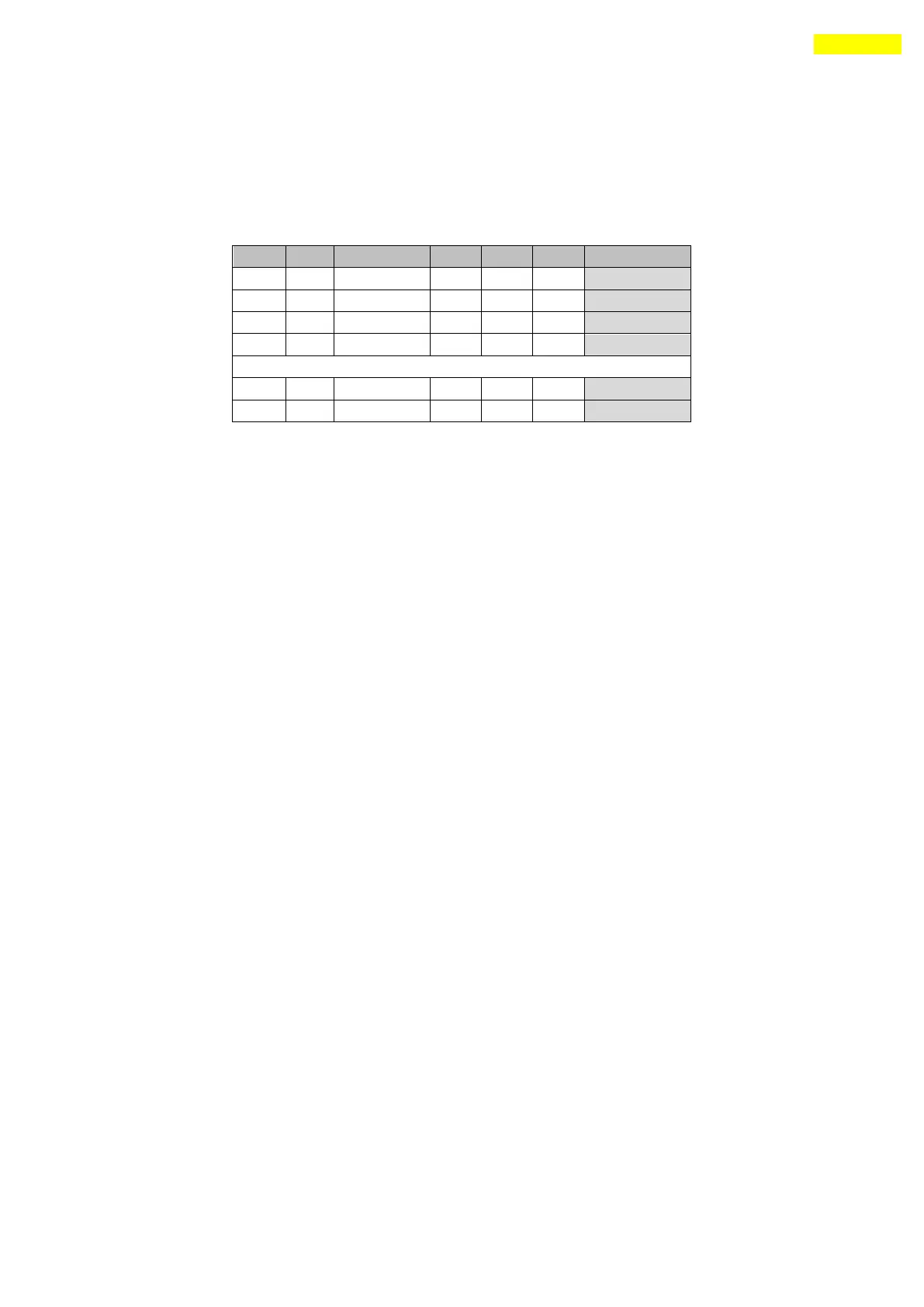

binary number. A0 is least significant bit and A7 is most significant bit. The following

table shows how to assign position table number.

*1. Save signal cabling : If‘PT A0~A7’signal is not connected when motioning by

‘PT Start’signal, the position table number will be ‘0’

… … … … … … … … … … … … … … … … … …

*2. ‘PT A5/UserIN 6’ ‘PT A6/UserIN 7’ ‘PT A7/UserIN 8’signal setting :

This signal can be used as‘PT A5~A7’, and also can be used as

‘User IN6~IN8’signal when the input signal ‘User IN0~IN5’is not enough.

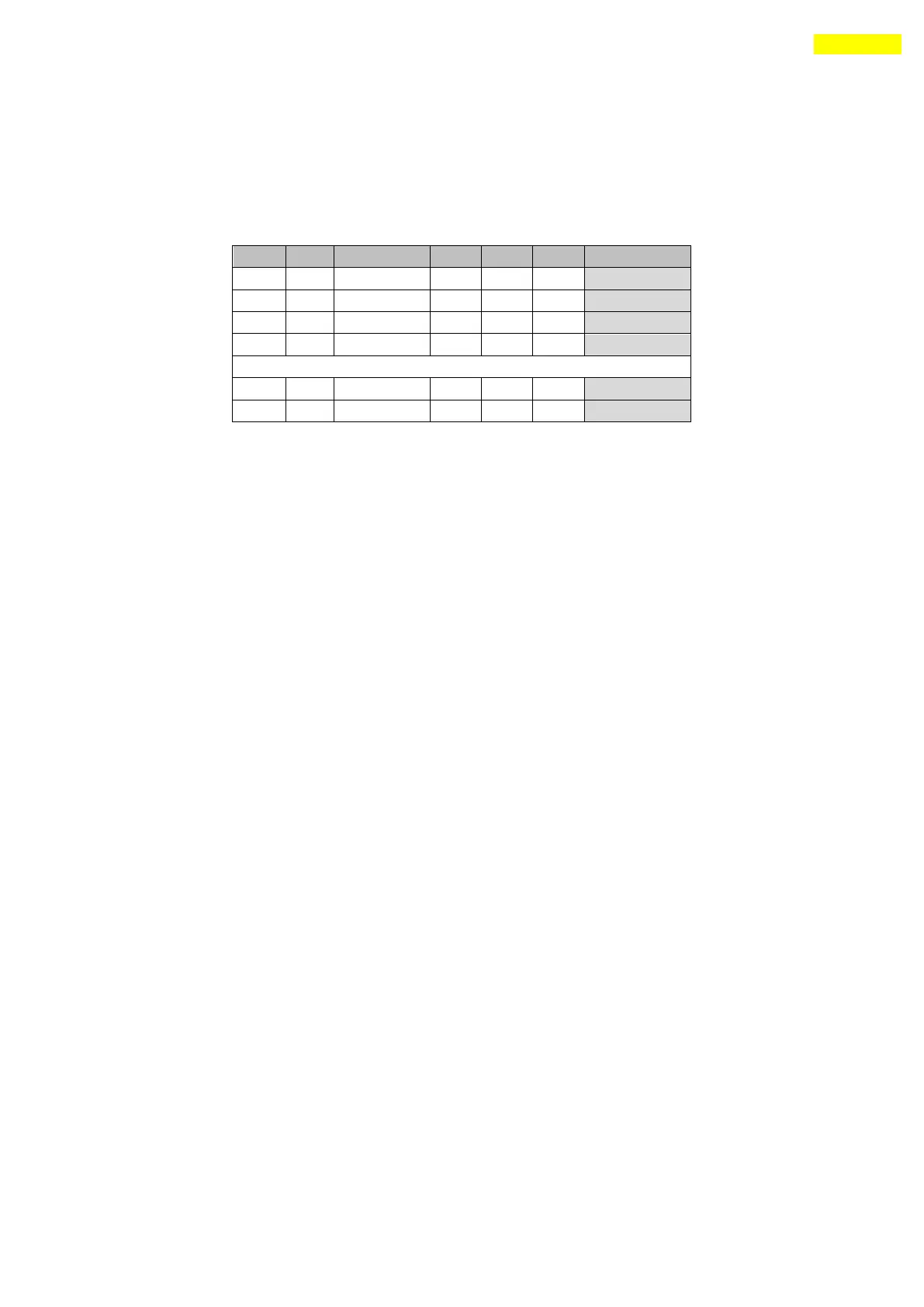

4) ‘Position Table Start (PT Start)’Input

By using PT A0~A7 signals, set and input the running PT start number. Then the motion

pattern corresponds to the PT No. will be executed.

Following example shows that total 6 motion patterns are in order executed from No.0 to

No.32 and then stopped.

1) All of PT A0~A7 is set to ‘0’ and PT number is set to ‘0’.

2) Set PT Start signal to [ON], and PT No.0 motion pattern will be executed.

3) When the motion pattern is started by PT, ACK signal and END signal are displayed to

[ON] at CN1 output port as illustrated below. The signal is kept until one motion

pattern loop is stopped. After all motions are stopped, the output signal level is

set to [OFF].

4) PT Start signal is edge trigger type and pulse scale is 10ms or more.

Loading...

Loading...