www.fastech.co.kr

10.4 Input Signal

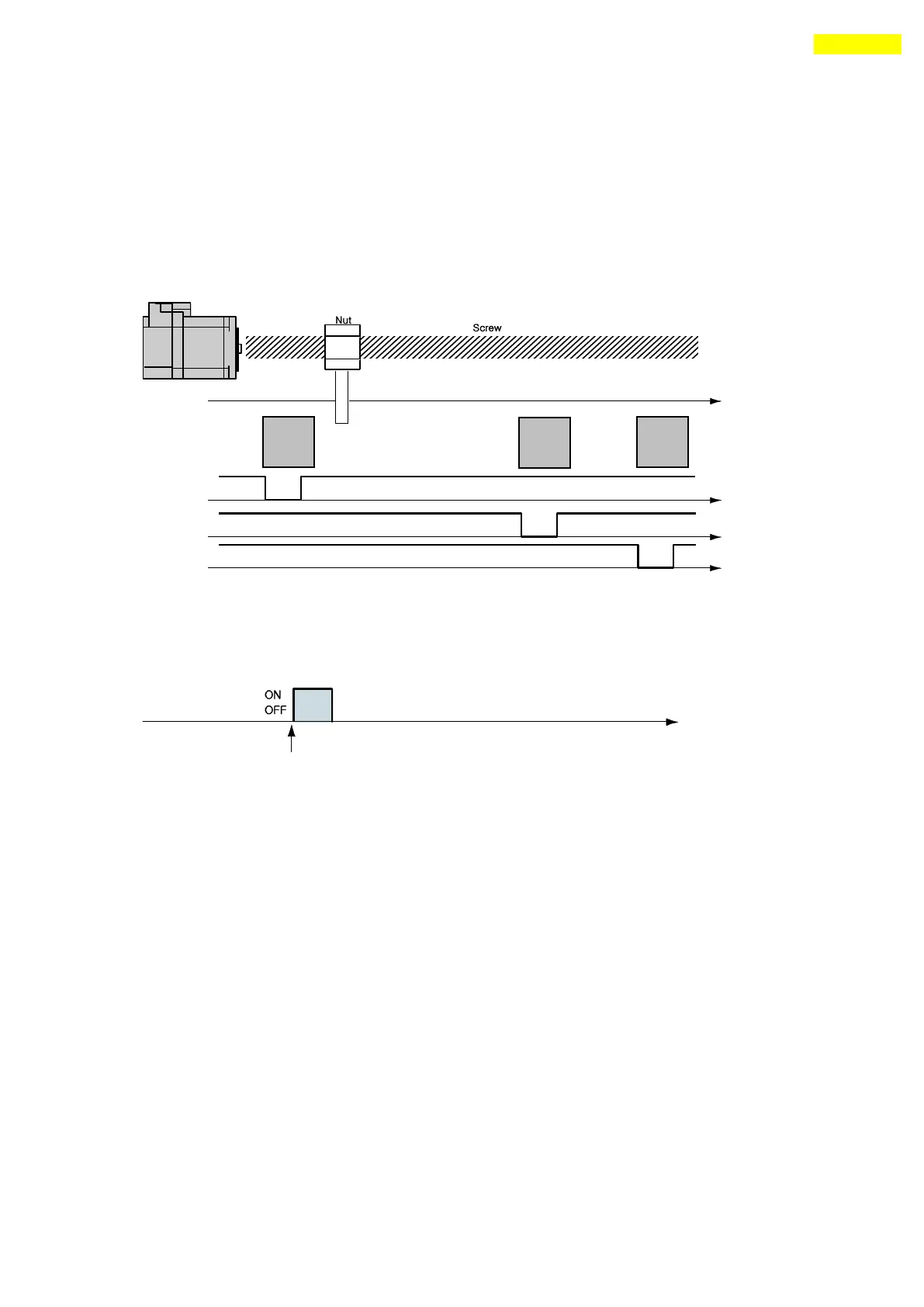

1) ‘Limit’ Sensor and ‘Origin’ Sensor

Limit sensor and origin sensor are assigned to LIMIT+, LIMIT- , and ORIGIN pin in the

CN1 connector respectively. LIMIT+ and LIMIT- sensors are used to limit the motion of

each axis clockwise and counterclockwise to prevent mechanical collision. Origin sensor

is to set the origin of equipment.

2) ‘Clear Pos’ Input

This input signal sets the command position and the actual position to 0 in relation to

motion position control. The reset signal pulse scale is 10ms or more.

3) ‘Position Table A0 – A7 (PT A0~A7)’Input

The position table supports the machine so that its motion can be controlled by I/O

signals of central controller. It can directly transmit commands such as position table

number, start/stop and origin return to the machine through the PLC. Also, the user can

check output signals such as in-position, completion of origin return and Servo ready

through the PLC.

「Position Table A0~A7」 inputs are total 8 bits of input signal. It is used to set 256

position table numbers. There are two application methods as follows.

* Ezi-SRERVO-PR-MI / Ezi-SERVO-ALL : maximum 64 position table numbers can be set.

1) To set position table number(0~255) to be set by ‘PT start’ input signal.

2) To set position table number(0~255) to save current position values by ‘Teaching’

input signal.

By using PT A0~A7 signals, the position table address can be set from 0 to 255 with a

Loading...

Loading...