32

9 REPLACING PARTS

Before carrying out any work, it is mandatory to:

- Lower the flail head to the ground

- Disconnect the power takeoff, stop the tractor and take the starting key out

- Wear working gloves

9.1 Flail replacement

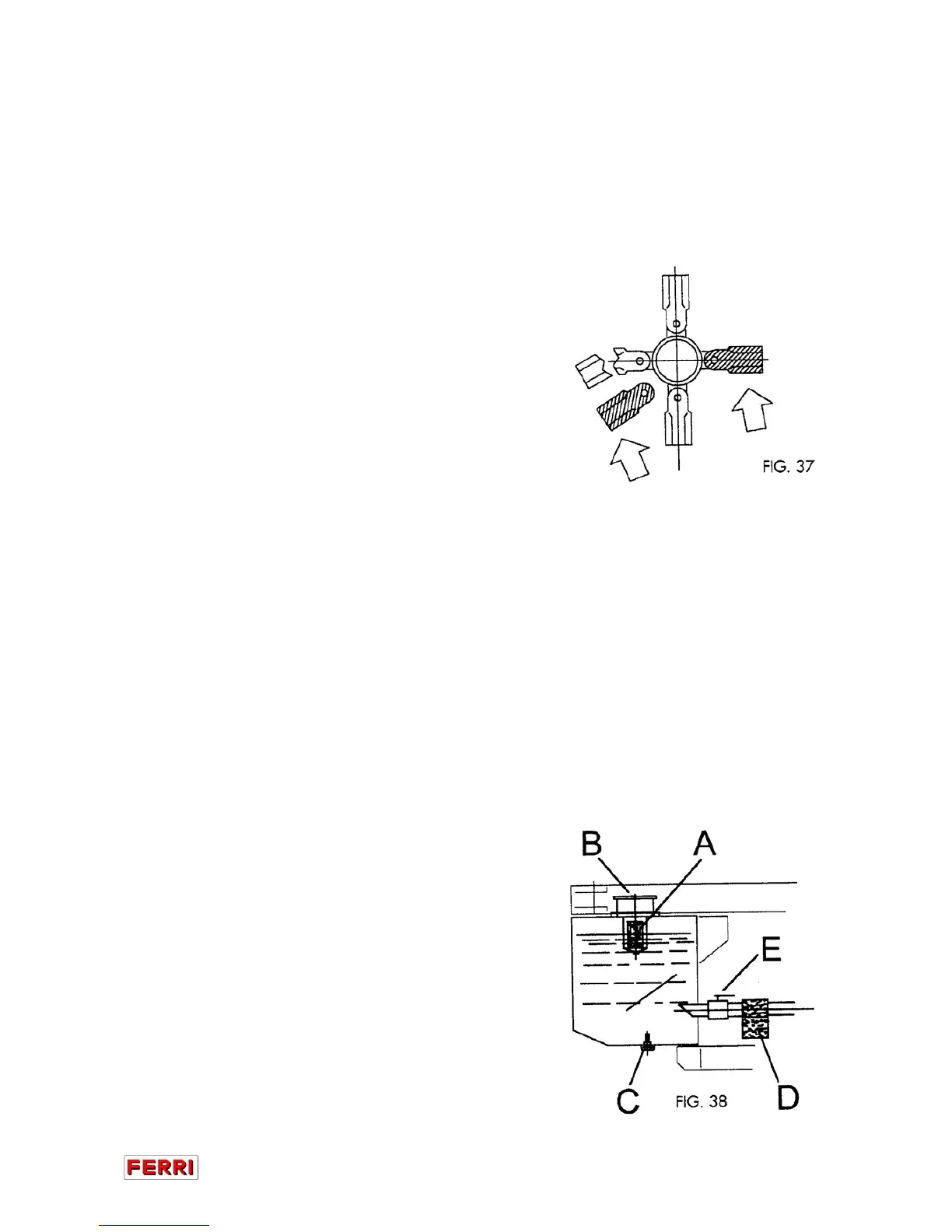

When the flails are worn, they must all be

replaced. In case of a partially broken flail, it is

advisable to replace the broken one and the

one diametrically opposite to it, in order to

maintain the balance (see Fig. 37).

9.2 Pipe replacement

- Before working on the hydraulic system, exhaust all pressure, working with the

engine stopped and using all control levers.

- Unscrew the filling cap on the oil tank to avoid the siphon effect, which could

empty the tank.

- Pay particular attention to cleanliness as dirt and dust can cause a great deal of

damage to the hydraulic system.

- Replace any damaged pipes with genuine spare parts, or with others of the same

specification; ensure that they are not kinked or twisted – remembering to check

this throughout the entire cycle of arm movement.

9.3 Pin replacement

- Carry out this operation wit the aid of a lift or hoist, to prevent detached

components falling, and also upsetting the balance of the machine.

- When replacing parts, clean and grease

their housing.

9.4 Oil and filter replacement

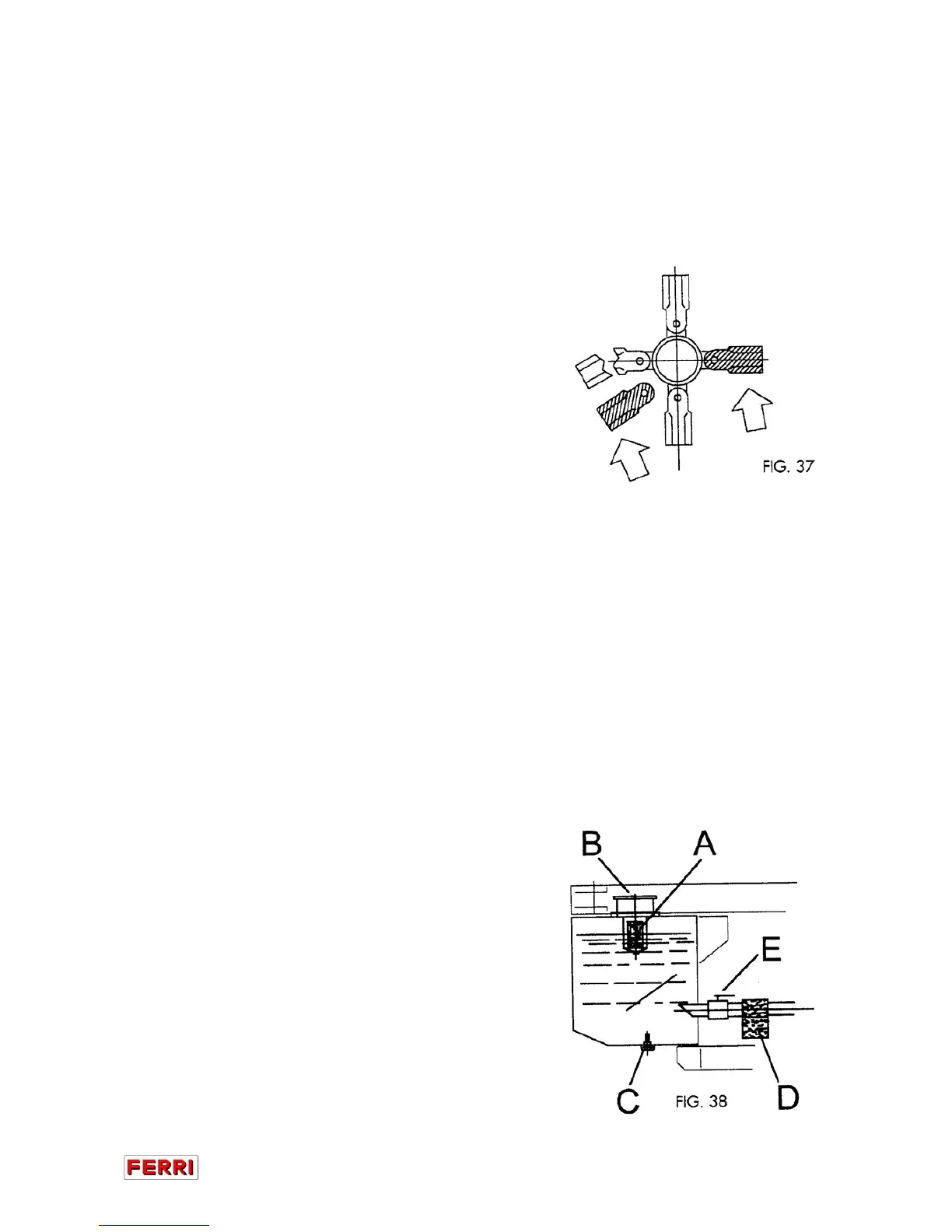

ATTENTION: Before doing any work on the

oil tank, SLOWLY UNSCREW THE FILLING

CAP B, to exhaust the pressure (0.4 Bar)

inside the tank.

- After the first 40 hours and then every 300

hours of operation, replace the oil filter (A)

(Fig. 38).

- For the system with the pistons pump,

replace the suction filter D at the same time

as the oil, after having closed the cock E.

Loading...

Loading...