5

Unit description

This new series of industrial chillers and heat pumps has been designed to meet the demands of global markets in the small-

medium power industrial and commercial plants. Units are compact and highly configurable, built to fit different types of plants

so to meet the needs of highly qualified engineers.

Units are water chillers and heat pumps condensed in air with axial fans suitable for outdoor installation: the structure and panels

are robust, made of galvanized and painted steel; all fasteners are made of stainless steel or galv

anized steel, the frame con-

taining the electrical equipment and all the components exposed to weather have a minimum IP54 degree of protection.

This series is composed of twelve models divided in four sizes with nominal cooling capacity from 53.5 to 200 kW and thermal

capacity from 57.5 to 214 kW.

The units product cold water from 5 to 25°C (in summer) and hot water from 30 to 55°C (in winter) and as standard they are

equipped with continuous adjustment of axial fans rotating speed in order to allow the units to operate both with low outdoor tem-

perature in cooling mode and with high outdoor temperature in heating mode as well as to reduce noise emissions.

All the units are equipped with 2 scroll compressors arranged in pairs (tandem) on 1 circuit operatin

g with environmental

friendly R410A gas, brazed plate heat exchanger completely insulated and protected by water side with a differential pressure

control and with an antifreeze electrical heater, coil heat exchanger made of louver aluminum fins and copper tubes, axial fans

with profiled blades to contain noise and with thermal protection built-in, on-board electrical control panel equipped with control

system to manage the main functions.

Hydronic group (MP) composed of fittings and connections is available as an accessory with 1 or 2 pumps and also with high

available head pumps or with Inverter modulating pump; the accessory Water Storage Tank (SAA) is completely insulated and

available on delivery side or for primary-secondary hydraulic circuit (Victaulic connections already in place) depending on the

kind of plants to serve.

A variety of other accessories are available to extend the capabilities of the units.

During the design of the units particular attention has been given to achieve high system efficiency, to reduce overall energy con-

sumptions and sound levels in order to meet the increasingly restrictive laws in terms of noise. Upon request, you can choose

for a Standard Unit (AB) or Low noise unit (AS) which provides sound attenuation thanks to sound absorbing insulation in com-

pressors area, sound jackets on compressors and reduced speed axial fans, or a Extra low noise unit (AX), which provides in

addition slower axial fans and more powerful finned coils.

All units are accurately build in compliance with the existing standards and are individually tested in factory. Only electrical and

hydraulic connections are required for installation.

GENERAL SPECIFICATIONS

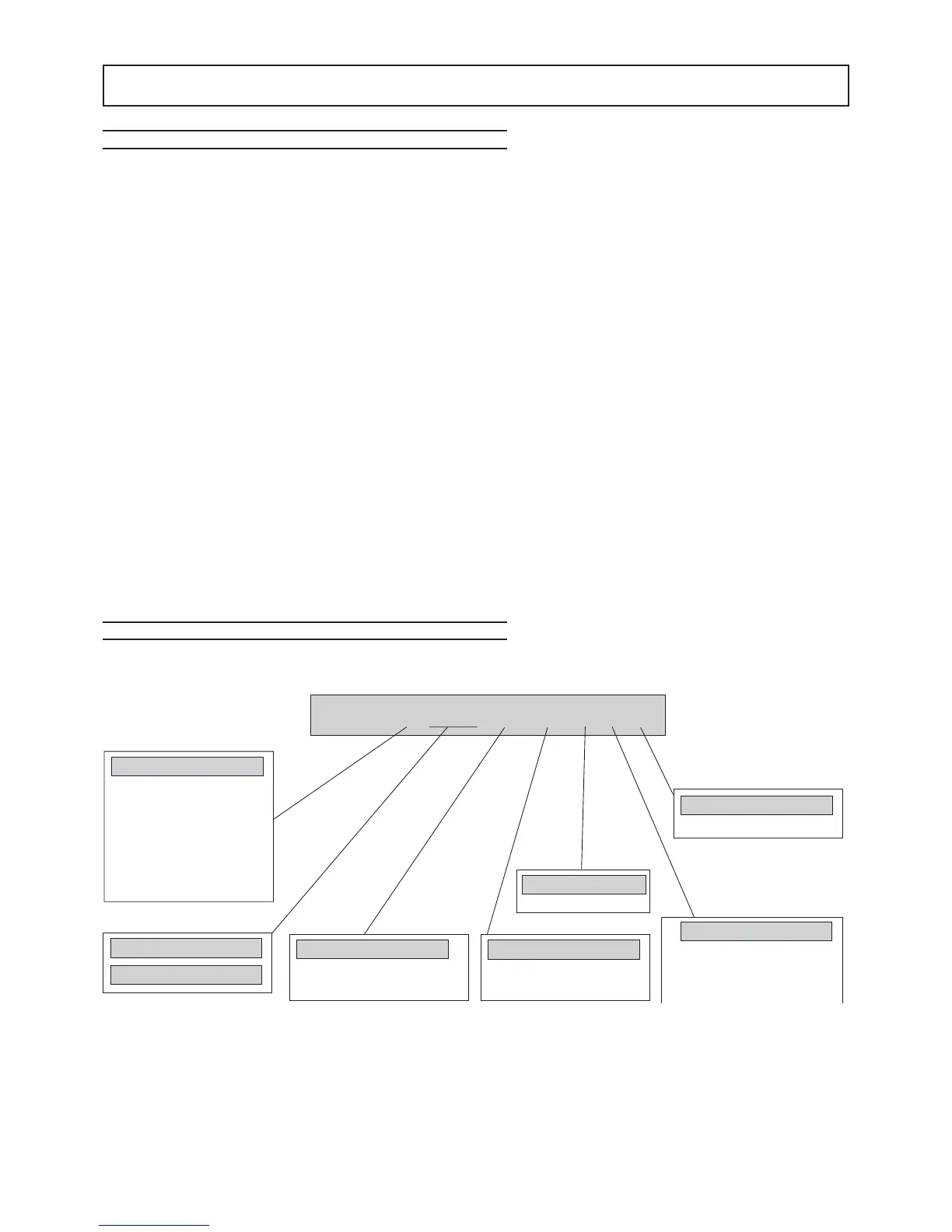

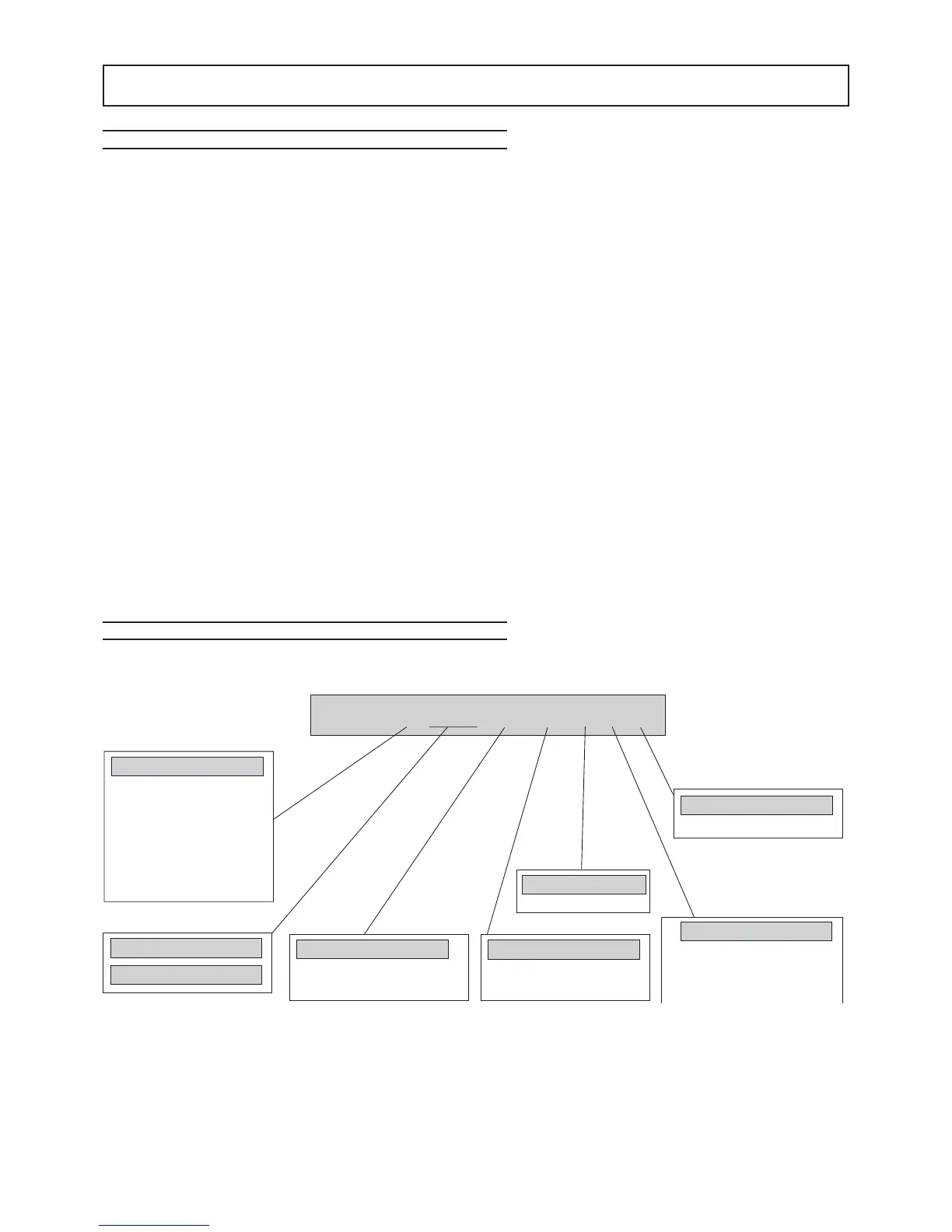

Identification code of the unit

The codes that identify the units are listed below and include the sequences of letters that determine

the meanings for the various versions and set-ups.

IR- units suitable for hydronic plant

installation operating as chillers.

IP- units suitable for hydronic plant

installation operating as heat pumps.

BR- units suitable for hydronic plant

installation with Brine solutions

operating as chillers.

BP- units suitable for hydronic plant

installation with Brine solutions

operating as heat pumps.

Unit version

Acoustic Version

AB - Standard unit

AS - Low noise unit

AX - Extra low noise unit

Unit model

N° Compressor

Type of Refrigerant

0 - R410A

Power Supply

5 - 400V-3ph~50Hz

Operating range

M - Medium temperature. Units are

suitable to be installed in temperate

climate sites.

A - High temperature. Units are suitable

to be installed in tropical climate sites.

Unit type

RGA IP - 50.2 - VB - AB - 0 - M - 5

VB - Standard Version

VD - Desuperheater unit

VR - Total heat recovery unit

The available special versions are described below:

VB: Standard unit.

VD: Desuperheater unit (available forboth IR units and IP units)

Produces cold water in the same way as the standard version plus hot water from 30 to 70°C at the same time. This is achieved by

installing a water-refrigerant gas heat exchanger between the compressor and coils in order to recover 15 to 20% of the heating capa-

city that would otherwise be dispersed in the air.

VR: Total Heat Recovery unit

Produces cold water as in the standard version plus hot water at a temperature of 35 to 50°C at the same time. This is achieved thanks

to a water-refrigerant gas heat exchanger that totally recovers the heating capacity that would otherwise be dispersed in the air. The

total heat recovery function is enabled and disabled by means of a valve on the compressor delivery of each circuit: when the tempe-

rature of the water that enters the recuperator drops, the valve switches the hot gas flow from the condensing coils to the recovery heat

exchanger. On the other hand, when the temperature of the water reaches the set-point, the valve shuts off the heat recuperator and

switches the hot gas flow to the condensing coils.

Loading...

Loading...