2.3 Foreseeable misuse of the STO function

The following are examples of foreseeable misuse and are not approved as

intended use:

– Bridging of the STO function.

–

Use in applications where switching off can result in hazardous movements or

conditions.

NOTICE

The STO function is not sufficient as the sole safety function for drives that are

subject to permanent torque or force (e.g. suspended loads, vertical axes).

Note

The STO function does not provide protection against electric shock, only against

dangerous movements!

2.4

Requirements for product use

–

Provide the complete product documentation to the following personnel:

– The design engineer and the installer of the machine or system.

– The personnel responsible for commissioning.

–

Keep this documentation safe throughout the entire product lifecycle.

– Ensure compliance with the specifications in this documentation. Also comply

with the documentation for the other components and modules (e.g. motor

controller, circuits, etc.).

– Observe all of the legal regulations applicable for the installation site and the

following documents:

– Regulations and standards.

–

Regulations of the testing organisations and insurers.

– National regulations.

For correct and safe use of the STO function:

–

Conduct a risk assessment for your machine.

– Comply with the specified safety characteristics

è

8 Technical data.

2.5 Product conformity

The motor controller with integrated STO safety function is a safety-related part of

the control systems. Certain configurations of the product have been certified by

Underwriters Laboratories Inc. (UL).

The product-relevant directives are listed in the declaration of conformity

è

www.festo.com/sp.

Product conformity

in accordance with EU EMC Directive

in accordance with EU Machinery Directive

in accordance with EU RoHS Directive

to UK EMC Regulations

to UK Supply of Machinery Regulations

to UK RoHS Regulations

Tab. 3:

Product conformity

2.6 Transport and storage conditions

– Protect the product during transport and storage from excessive stress factors,

such as:

– Mechanical loads.

– Temperatures that are too high or too low.

–

Moisture.

– Aggressive atmospheres.

–

Store and transport the product in its original packaging. The original pack-

aging offers sufficient protection from typical stresses.

2.7 Technical prerequisites

For correct and safe use of the product:

–

Carry out a risk assessment for your machine or system.

– Comply with the specified safety characteristics

è

8 Technical data.

–

Comply with the specified connection and ambient conditions for all connected

components

è

8 Technical data. Only compliance with the limit values and/or

load limits will enable operation of the product in accordance with the relevant

safety directives.

3

Product overview

3.1 Scope of delivery

Component Number

Motor controller CMMO-ST-C5-1-LKP 1

Documentation for the product:

– Brief documentation for the CMMO-ST + quick guide for positioning systems

(OMS)

– Special documentation corresponding to the certifications of the product

1

Assortment of plugs NEKM-C-14 with 6 connectors for control interface [X1], refer-

ence switch [X1A], safety function STO [X3], encoder [X2], motor [X6], power supply

[X9]

1

H-rail bracket, pre-assembled 1

Tab. 4:

Scope of delivery

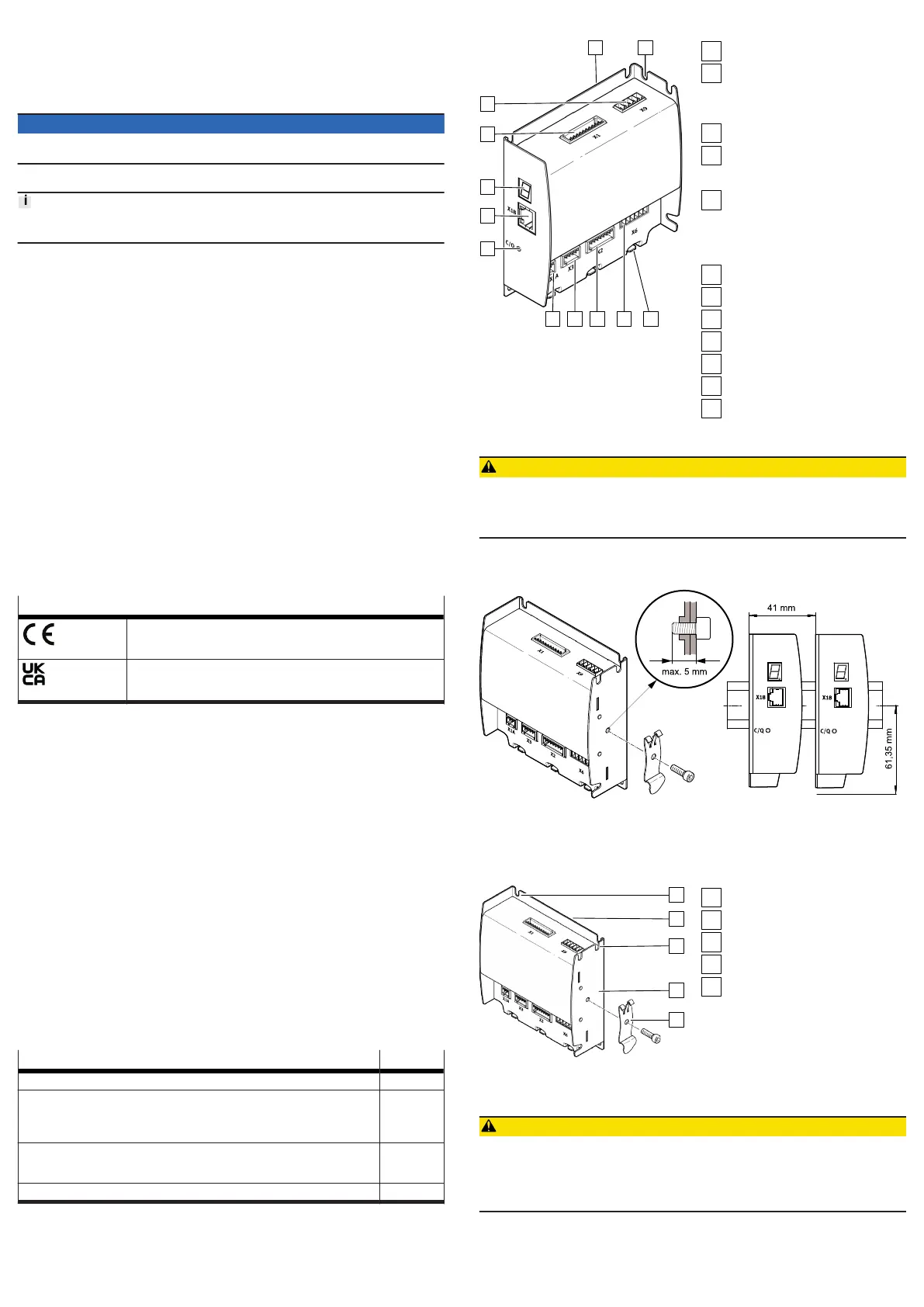

3.2 Product design

Fig. 1: Components of the CMMO-ST

[X9] Load/logic voltage

[X1] control interface to open-loop

control with PLC/IPC

– IO-Link/I-Port

– optional: digital I/Os

7-segment display

[X18] Ethernet (RJ-45)

– TCP/IP parameterisation interface

– Modbus TCP control interface

Link/activity LED C/Q

– LED green: communication OK

– LED red: communication error

– LED off: IO-Link/I-Port is not config-

ured as control interface

[X1A] reference switch

[X3] STO (Safe torque off)

[X2] encoder RS422

[X6] motor

FE functional earth (3x)

Mounting surface (H-rail)

Mounting surface

4

Mounting

CAUTION

Unexpected and unintended movement of the drive during mounting, installation

and maintenance work.

• Before starting work: switch off power supplies.

• Lock the power supplies to prevent accidental reactivation.

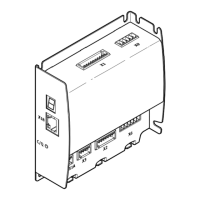

4.1 Mounting the motor controller

The controller can be mounted with an H-rail or on an even surface.

Fig. 2:

Mounting on an H-rail

Mount the CMMO-ST on the H-rail as follows:

1.

Attach the CMMO-ST to the H-rail from above with the hook of the H-rail clip.

2. Press down on the H-rail until the CMMO-ST clicks into place.

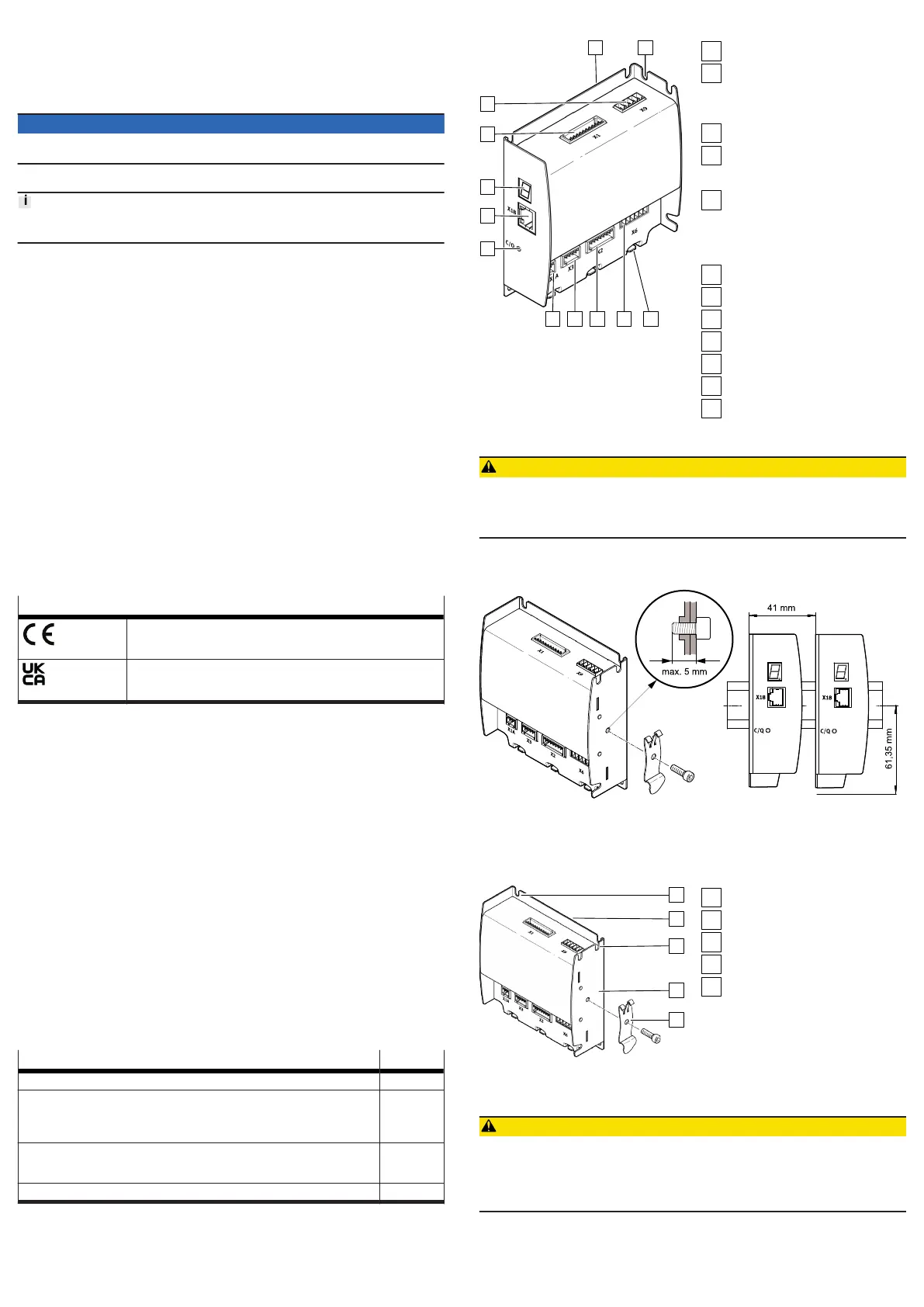

Mount the CMMO-ST on the side or rear mounting surface as follows:

Fig. 3:

Mounting on an even surface

Remove the H-rail bracket

Rear mounting surface

Notches (3x) for rear mounting

Side mounting surface

Recesses (4x) for side mounting

5

Electrical installation

CAUTION

Unexpected and unintended movement of the drive during mounting, installation

and maintenance work.

• Before starting work: switch off power supplies. Cancelling the enable signal on

the controller is not sufficient.

• Lock the power supplies to prevent accidental reactivation.

Loading...

Loading...