6. Install new filter cartridge:

– Hold filter cartridge at the bottom and push onto the support.

– Position filter plate, screw in and hand-tighten. Tightening torque:

0.07Nm ±20%

7. Mount filter bowl 5:

– Align lock release of filter bowl on the cutout on the housing and insert it.

– Turn filter bowl clockwise until the lock audibly locks at the end stop.

9.3 Clean product

• Clean the outside of the product with a soft cloth as required. Cleaning agents

include all non-abrasive media.

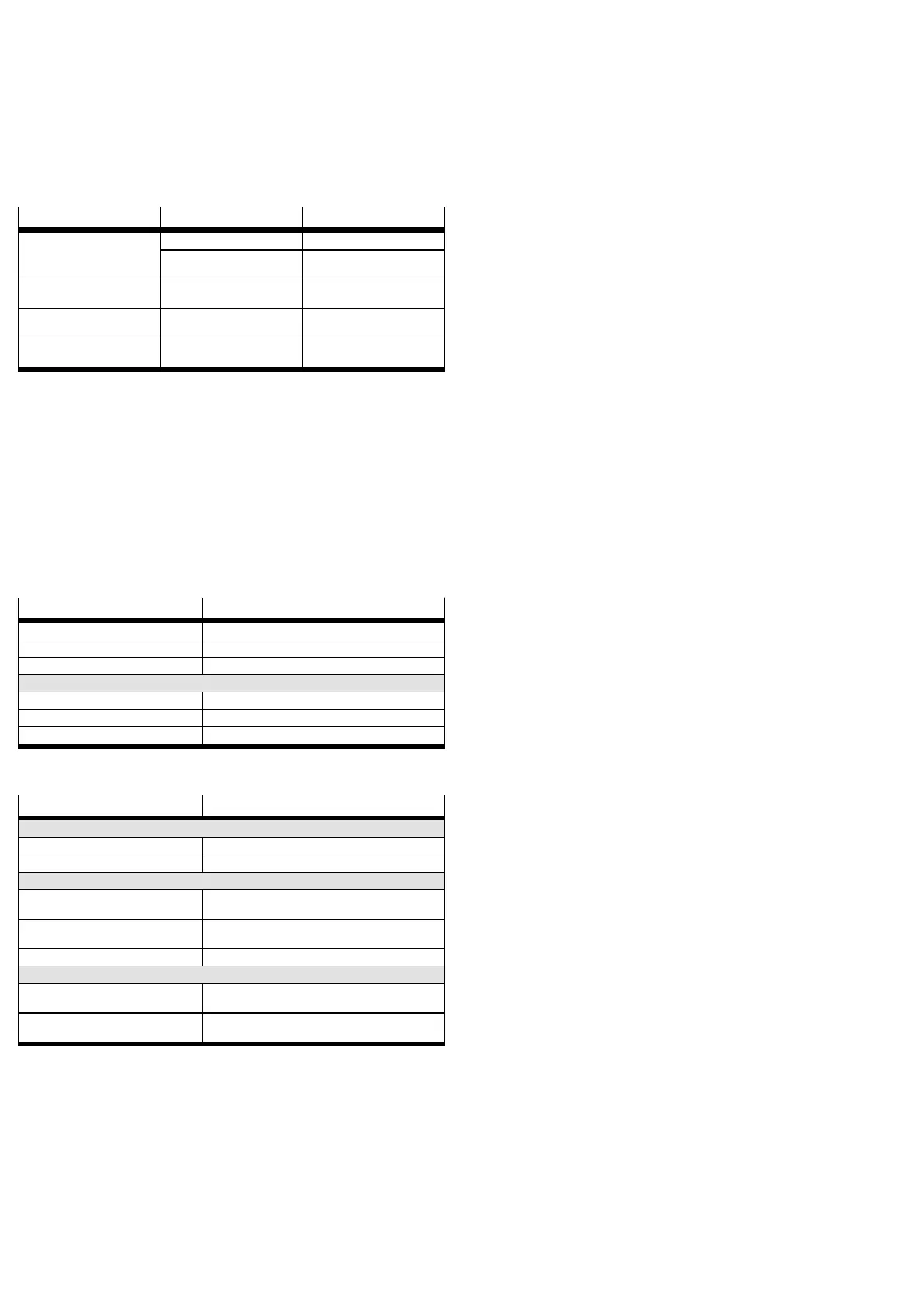

10 Fault clearance

Error description Cause Remedy

Constriction in the supply line Check supply line.Low flow rate (operating pres-

sure breaks down with air con-

sumption)

Filter cartridge dirty Replace filter cartridge

è 9 Maintenance.

Pressure increases above the

set working pressure.

Valve disc defective at sealing

seat

Replace product.

Audible, continuous blowing

noise at rotary knob

Valve seat damaged Replace product.

Blowing noise can be heard at

the drain screw.

Drain screw leaking Replace product.

Tab. 3 Fault clearance

11 Disassembly

1. Exhaust the complete system and product.

2. Release interlock at the fittings by pressing it and pull out hose assembly.

3. Release fittings at the connecting flanges and unscrew.

12 Disposal

• Dispose of the packaging, used filters and product at the end of the produc-

tion service life according to the valid provisions for environmentally sound

recycling.

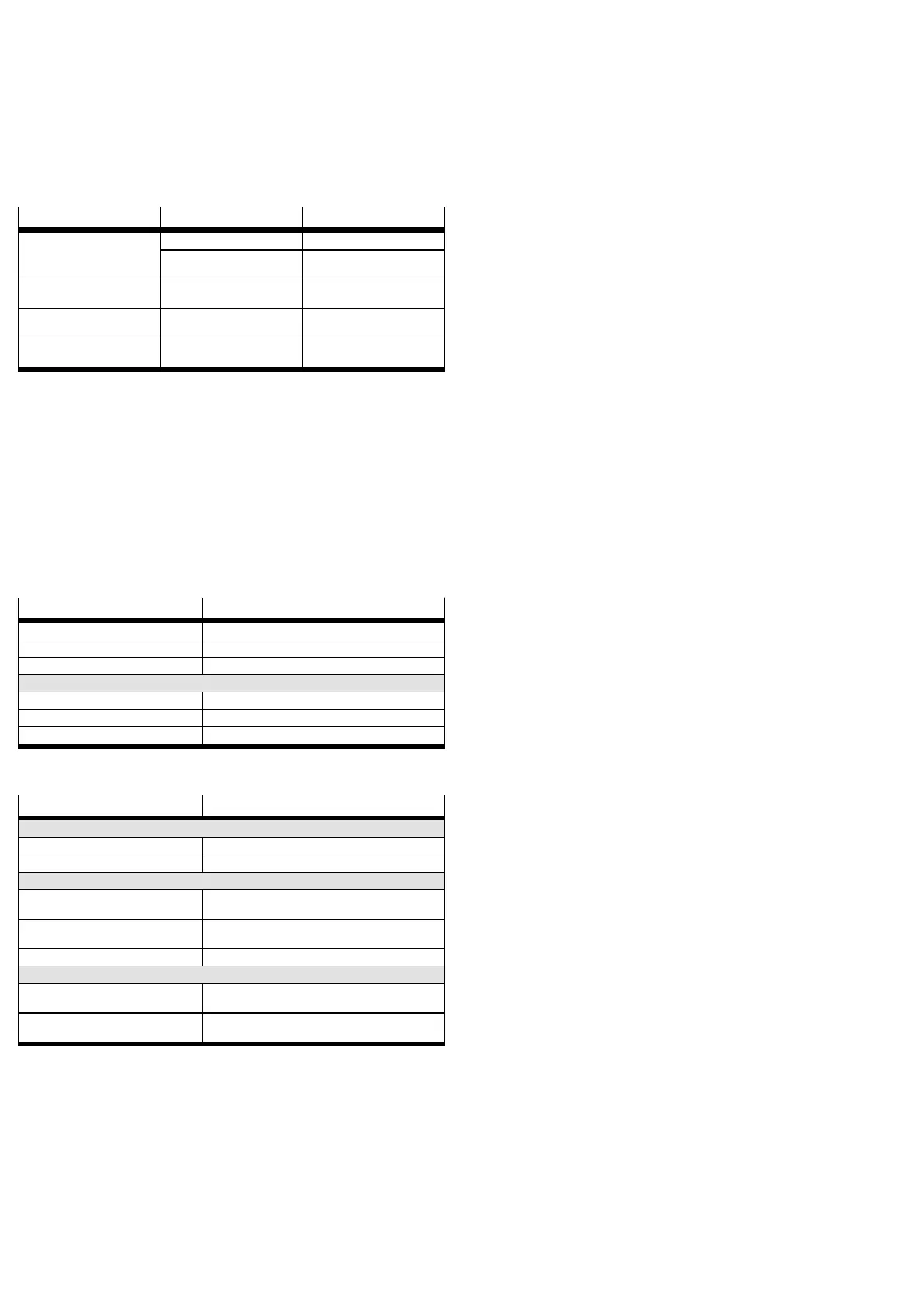

13 Technical data

13.1 Technical data, mechanical

Size MS2-LFR

Mounting position [°] vertical +/– 5

Grade of filtration [µ] 5

Condensate drain function manual turning

Temperature ranges

Temperature of medium [°C] –5…50

Ambient temperature [°C] –5…50

Storage temperature [°C] –5…50

Tab. 4

13.2 Technical data, pneumatic

Size MS2-LFR

Compressed air quality

Operating medium Compressed air to ISO8573-1:2010 [7:4:4]

Air quality class at the output Compressed air to ISO8573-1:2010 [6:4:4]

Pneumatics

Pneumatic connection

M5

[bar] 1…10

Pneumatic connection

QS6

[bar] 1…8

Pressure regulation range [bar] 0.5…7

Standard nominal flow rate

Pneumatic connection

M5

[l/min] 140

Pneumatic connection

QS6

[l/min] 310

Tab. 5

Loading...

Loading...