Do you have a question about the Festo SEC-AC-508 and is the answer not in the manual?

Details on correctly installing and fitting the drive, including checks for mounting and workspace.

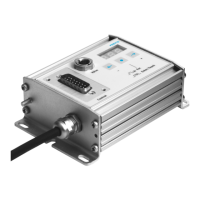

Procedure for checking the SEC-AC's readiness, including controller enable switch and LED indicators.

Step-by-step guide to install the SEC-AC parametrizing program on your hard disk using SETUP.EXE.

Details on establishing communication between the PC and the servo controller via the serial interface.

Troubleshooting guide for serial interface issues, including error window scenarios and solutions.

Provides a table of common serial communication faults and their corresponding remedies for resolution.

Explains user modes (Beginner, Advanced, Expert) for accessing program functions and their impact on settings.

Procedure for transferring pre-tested parameter sets from the CD to the SEC-AC controller.

Instructions for setting maximum and rated current values for the motor to prevent damage.

Configuring the logic that determines when the controller can be enabled, based on digital inputs.

Explains automatic identification of motor parameters like pole pairs and offset angle for correct functioning.

Details on setting amplification factor and time constant for the current controller for optimal motor performance.

Assigning sensible basic values for the speed controller before actual optimization.

Procedure for testing the controller enable function, including safety precautions and parameter saving.

Guidelines for setting the speed controller parameters for optimal performance, including setpoint jumps.

Using the oscilloscope function to optimize the speed controller, including reversing the motor safely.

Setting up and optimizing the positioning module, which forms a speed result from positional differences.

Configuration of the positioning module as P-controller or PI-controller, specifying gain and time constant.

Explanation of offset angle, its importance for drive functioning, and pole pair matching.

How the SEC-AC automatically determines motor parameters like pole pairs and phase sequence.

Setting up positioning mode, specifying target position, and how deviation is processed by the positioning module.

Master specifies speed to slave; slave moves at this speed. Position is not controlled.

Master specifies position to slave; slave moves to this position. Speed feedback is recommended.

Using the oscilloscope function to represent signal curves and optimize controllers, including reverse mode.

Table of error codes, their meanings/functions, and measures for rectifying the faults.

| Number of digital inputs | 8 |

|---|---|

| Number of digital outputs | 8 |

| Number of analogue inputs | 2 |

| Protection class | IP20 |

| Analogue input signal | 0 V ... 10 V |

| Ambient temperature | 0 °C ... 50 °C |

| Storage temperature | -20 °C ... 70 °C |

| Current consumption | 0.3 A (24 V DC) |