Do you have a question about the Festo SPC11-POT-TLF and is the answer not in the manual?

Details the different types of SPC11 and their connection capabilities.

Explains the functional principles and closed-loop control circuit of the SPC11.

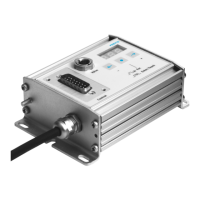

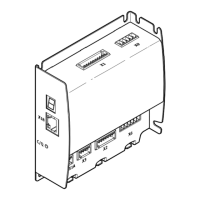

Illustrates the physical interface, display, and various connection ports on the SPC11 unit.

Provides mounting instructions, dimensions, and fastening details for the SPC11.

Covers essential safety warnings and general guidelines before starting installation.

Details requirements for compressed air supply, service units, and tubing connections.

Explains the implementation of pneumatic emergency stop functions for system safety.

Guidance on electronic component installation, including cable placement and interference reduction.

Identifies and shows the location of key connection interfaces on the SPC11.

Instructions for safely connecting the power supply and input/output signals.

Procedures for connecting the proportional directional control valve and measuring system.

Provides an overview of the commissioning process, safety, and key functions.

Explains key parameters like amplification and cushioning stages for SPC11 operation.

Steps for setting initial parameters remotely before connecting the drive.

Procedures for changing existing parameters and restoring factory defaults.

A comprehensive step-by-step guide for the entire commissioning process.

Essential checks and prerequisites before initiating the teach procedure.

Detailed instructions on how to begin the automatic teach procedure.

Method for manually teaching and saving up to two mid-positions.

Important safety instructions for switching the system on and off.

Describes the system's status and readiness upon power-up after setup.

How the system verifies direction and handles errors during initial operation.

Using command inputs and remote inputs for manual and automated control.

Explains how to utilize learned mid-positions as sensor inputs for control logic.

Lists specific error codes, their meanings, and troubleshooting steps.

Identifies common operational problems and provides remedies.

Guidance on adjusting parameters to enhance motion control and performance.

Details the function and usage of remote inputs (I5-I7) for external control.

General overview and conditions for parameter setting using digital inputs.

Illustrates the timing sequence for setting parameters using digital inputs.

Timing diagram showing how to initiate the teach procedure via digital inputs.

Timing diagram for the process of teaching mid-positions using digital inputs.

Contains detailed technical data including dimensions, supply, and interface specifications.

An alphabetical listing of terms and their corresponding page numbers for quick reference.

| Brand | Festo |

|---|---|

| Model | SPC11-POT-TLF |

| Category | Controller |

| Language | English |