Go to fetco.com for the latest versions of all information Page 9 User Guide & Operator instructions P194Re0 November 2020

Operator Training

Review the operating procedures with whoever will be using the brewer.

Pay particular attention to the following areas:

1. Always pre-heat the dispensers before the first use of each day by filling them half way with hot water, and letting

them stand for at least 5 minutes.

2. Do not remove the brew basket from a coffee brewer until it has stopped dripping.

3. Make sure the dispenser is empty before brewing into it.

4. Show how to attach covers, close, and or secure the dispensers for transporting.

5. Show the location and operation of the water shut off valve as well as the circuit breaker for the brewer.

6. Steam from the tank will form condensation in the vent tubes. This condensation will drip into and then out of the

brew baskets. Up to 1/4 cup/118cc discharging overnight is possible. Place an appropriate container under each

brew basket when not in use.

7. We recommend leaving the power to the brewer on overnight. The water tank is well insulated and very little

electricity is used to keep the tank hot. Leaving the brewer in the “ON” position will also avoid delays at the beginning

of shifts for the brewer to reach operating temperature.

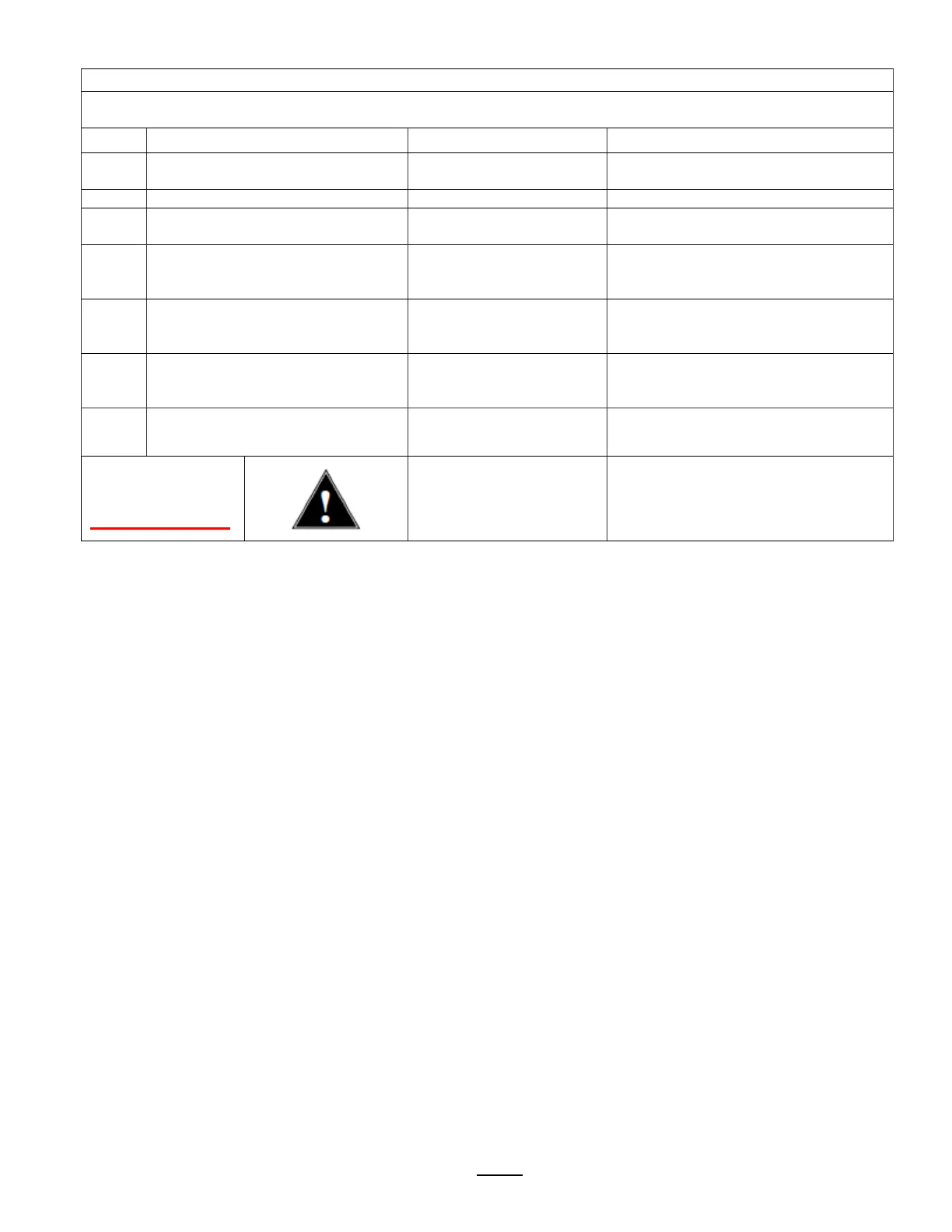

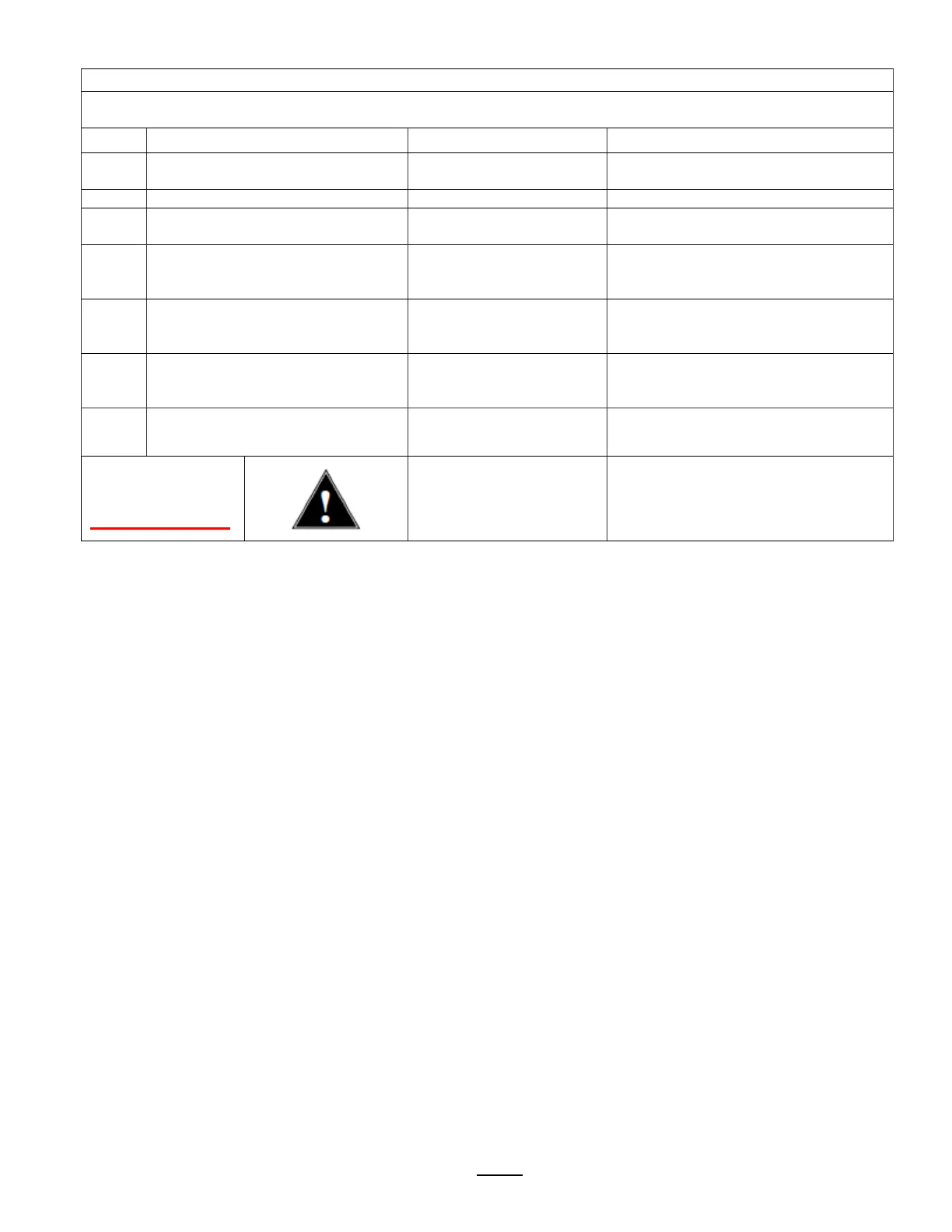

ERROR CODES

DO NOT CLEAR ERROR CODES UNTIL ERROR IS IDENTIFIED AND/OR CORRECTED

Contact specialized personnel for error codes

Code Description Possible Cause Corrective Action

001

Software error-error on start up or

corrupted software

Improper start-up or

shutdown

Restart , if still fault: reload software

050 Short-circuit in temperature probe Probe failure. Replace probe.

051 Open temperature probe.

Bad probe connection, or

probe failure.

Check all connections. Replace probe

if necessar

.

100

Initial Fill Error.

Initial fill time took longer than

expected after power up.

Water supply flow rate is

too low.

Watch for short potting during brew

cycle. Investigate cause of low flow

rate.

Clo

ed water filter...

101

Error on refill-.

Tank did not refill within expected

time.

Water supply flow rate is

too low.

Watch for short potting during brew

cycle. Investigate cause of low flow

rate.

Clo

ed water filter…

201

Heater open, high limit thermostat,

or Solid State Relay (SSR) fault

Failure of heating element,

SSR, high limit or low

volta

e

Check and replace heating elements,

SSRs, high limit devices if necessary.

255 Touch pad error

Usually from longer than 2

min contact. Or faulty

reassembly after service

Restart , if still fault: reload software.

If mechanical: replace module

NO

BSKT

Insert Brew Basket

Brew basket must be in

place

This is a

SAFETY FEATURE

Insert brew basket into brewer rails to

enable brewer

Loading...

Loading...