INITIAL INSPECTION:

Be certain to inspect all cartons or crates on each unit as

received at the job site before signing the freight bill.

Verify that all items have been received and that there are

no visible damages; note any shortages or damages on

all copies of the freight bill. In the event of damage or

shortage, remember that the purchaser is responsible for

filing the necessary claims with the carrier. Concealed

damages not discovered until after removing the units

from the packaging must be reported to the carrier within

15 days of receipt.

GENERAL DESCRIPTION:

The GO Water-to-Air Heat Pumps provide the best

combination of performance and efficiency available.

Safety devices are built into each unit to provide the

maximum system protection possible when properly

installed and maintained.

The GO Water-to-Air Heat Pumps are Underwriters

Laboratories (UL) and (cUL) listed for safety. The water-

to-Air Heat Pumps are designed to operate with entering

fluid temperature between 25°F to 75°F in the heating

mode and between 50°F to 110°F in the cooling mode.

NOTE: 50°F Min. EWT for well water applications with

sufficient water flow to prevent freezing. Antifreeze

solution is required for all closed loop applications.

Cooling Tower/Boiler and Earth Coupled (Geo Thermal)

applications should have sufficient antifreeze solution to

protect against extreme conditions and equipment failure.

Frozen water coils are not covered under warranty.

NOTE: This product should not be used for temporarily

heating/cooling during construction. Doing so may effect

the units warranty.

MOVING AND STORAGE:

If the equipment is not needed for immediate installation

upon its arrival at the job site, it should be left in its

shipping carton and stored in a clean, dry area. Units

must only be stored or moved in the normal upright

position as indicated by the "UP" arrows on each carton

at all times. If unit stacking is required, stack units as

follows: Vertical units less than 6 tons, no more than two

high. Horizontal units less than 6 tons, no more than

three high. "Do not stack units larger than 6 tons."

SAFETY CONSIDERATIONS:

Installation and servicing of this equipment can be

hazardous due to system pressure and electrical

components. Only trained and qualified personnel should

install, repair, or service the equipment. Untrained

personnel can perform basic functions of maintenance

such as cleaning coils and replacing filters.

WARNING: Before performing service or maintenance

operations on the system, turn off main power to the unit.

Electrical shock could cause personal injury or death.

When working on equipment, always observe precautions

described in the literature, tags, and labels attached to

the unit. Follow all safety codes. Wear safety glasses and

work gloves. Use a quenching cloth for brazing, and

place a fire extinguisher close to the work area.

LOCATION:

Locate the unit in an indoor area that allows easy removal

of the filter and access panels, and has enough room for

service personnel to perform maintenance or repair.

Provide sufficient room to make fluid, electrical, and duct

connection(s). If the unit is located in a confined space

such as a closet, provisions must be made for return air

to freely enter the space. On horizontal units, allow

adequate room below the unit for a condensate drain trap

and do not locate the unit above supply piping. These

units are not approved for outdoor installation; therefore,

they must be installed inside the structure being

conditioned. Do not locate in areas that are subject to

freezing.

INSTALLATION:

NOTE: Remove all shipping blocks under blower

housing. Loosen compressor mounting bolts.

MOUNTING VERTICAL UNITS:

Vertical units up to

five tons are available

in left, right, front, or

rear air return

configurations.

Vertical units should

be mounted level on

a vibration absorbing

pad slightly larger

than the base to

minimize vibration

transmission to the

building structure. It

is not necessary to

anchor the unit to the

floor. (See Figure #1).

Vertical units larger than five tons should be vibration

isolated according to the design engineers specifications.

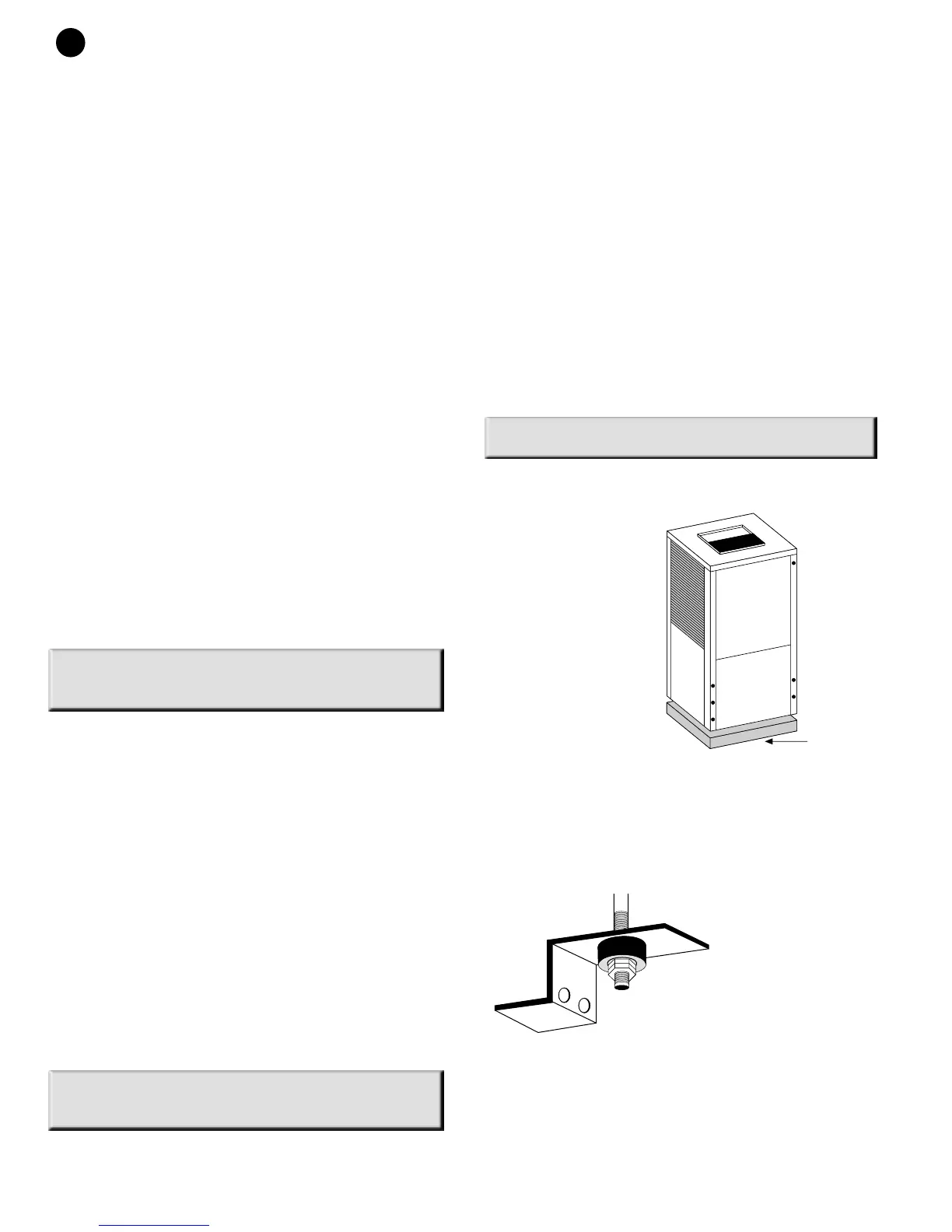

MOUNTING HORIZONTAL UNITS:

While horizontal units may be installed on any level

surface strong enough

to hold their weight,

they are typically

suspended above a

ceiling by threaded

rods. The rods are

usually attached to

the unit corners by

hanger bracket kits

(P/N 930-004, 006).

(See Figure #2). The

rods must be

securely anchored to the ceiling. Refer to the hanging

bracket assembly and installation instructions for details.

Models GO 042 and up require six brackets (930-

006).(See unit horizontal detail drawing). Horizontal units

installed above the ceiling must conform to all local

codes. An auxiliary drain pan if required by code, should

be at least four inches larger than the bottom of the heat

2

GO SERIES

(Figure #2)

(Figure #1)

VIBRATION

PAD

FULL SIZE

Loading...

Loading...