Serious damage or erosion of the water to refrigerant

heat exchanger could occur.

Always check carefully for water leaks and repair

appropriately. Units are equipped with female pipe thread

fittings. Consult the specification sheets for sizes. Teflon

tape sealer should be used when connecting water piping

connections to the units to insure against leaks and

possible heat exchanger fouling. Do not overtighten the

connections. Flexible hoses should be used between the

unit and the rigid system to avoid possible vibration. Ball

valves should be installed in the supply and return lines

for unit isolation and unit water flow balancing.

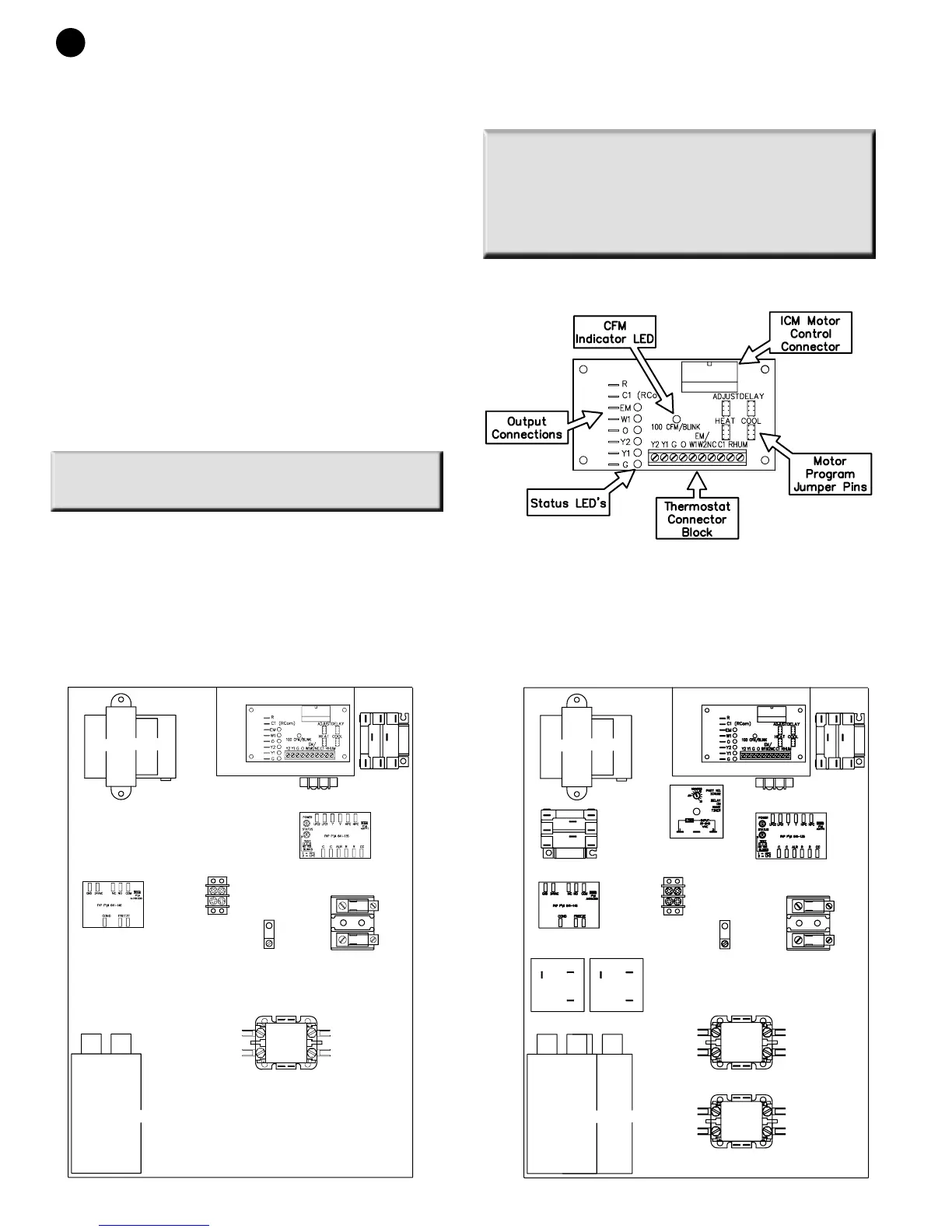

ELECTRICAL:

(Refer to electrical component box layout, Figure #5)

Field wiring must comply with local and national electric

codes. Power to the unit must be within the operating

voltage range indicated on the unit nameplate. or on the

performance data sheet. On three phase units (single

steps units only) phases must be balanced within 2%.

CAUTION: Operation of unit on improper line voltage or

with excessive phase imbalance will be hazardous to the

unit, constitutes abuse and may void the warranty.

Properly sized fuses or HACR circuit breakers must be

installed for branch circuit protection. See unit nameplate

for maximum fuse or breaker size.

The unit is provided with a concentric knock-out in the

front left corner post for attaching common trade sizes of

conduit, route power supply wiring through this opening.

Always connect the ground lead to the grounding lug

provided in the control box and power leads to the power

supply terminal block as indicated on the wiring diagram

and Figure #5.

NOTE: Units supplied with internal electric heat require

two (2) separate power supplies: one for the unit

compressor and one for the electric heater elements,

blower motor and control circuit. Refer to the ELECTRIC

HEATER PACKAGE OPTION section and Figure #8 and

#9 for wiring instructions, minimum circuit ampacities and

maximum fuse/breaker sizing.

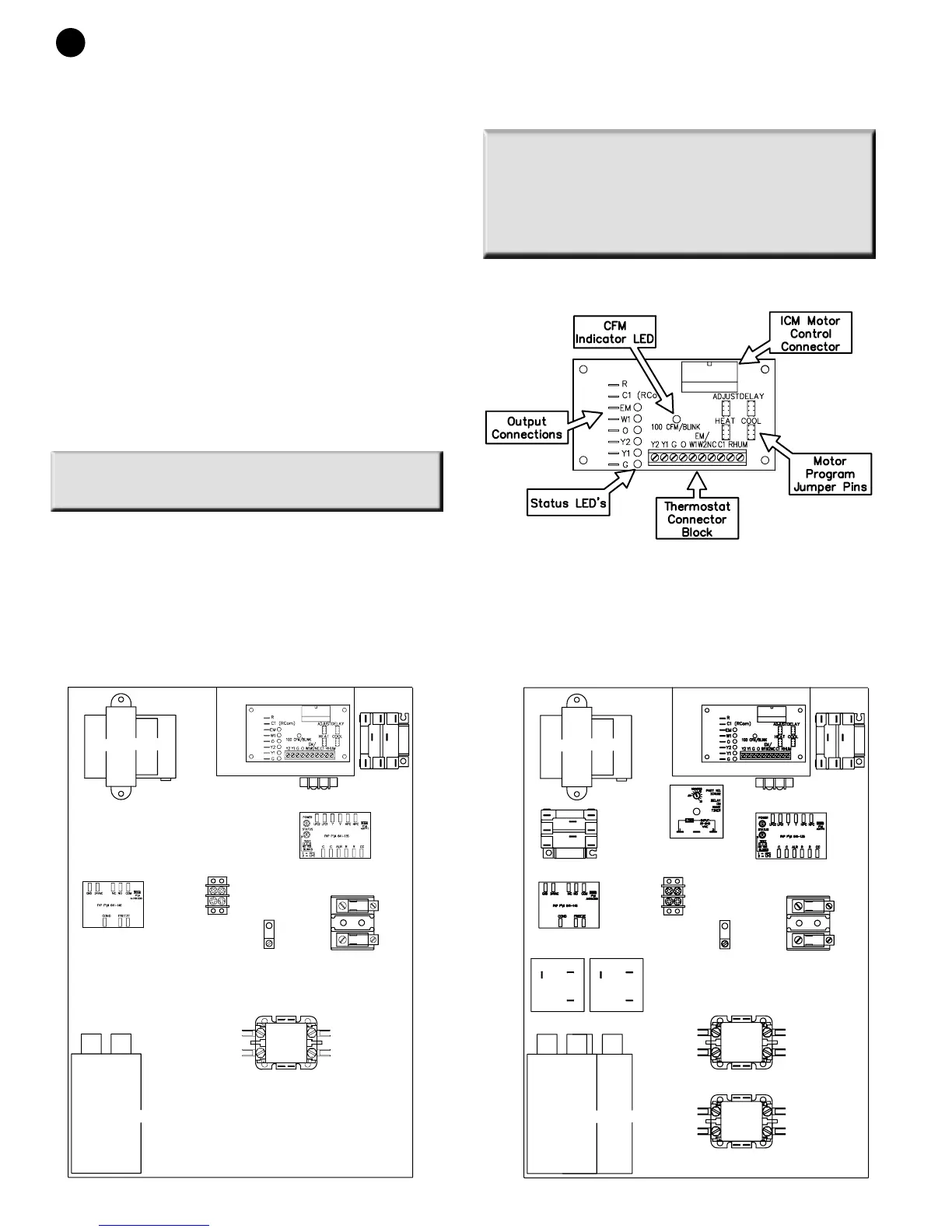

ICM INTERFACE BOARD:

THERMOSTAT CONNECTIONS:

Thermostat wiring is connected to the 10 pin screw type

terminal block on the lower center portion of the ICM

Interface Board. In addition to providing a connecting

4

GO SERIES

(Figure #6)

(Figure #5)

Electrical Box

Component

Layout

Loading...

Loading...