8

GO SERIES

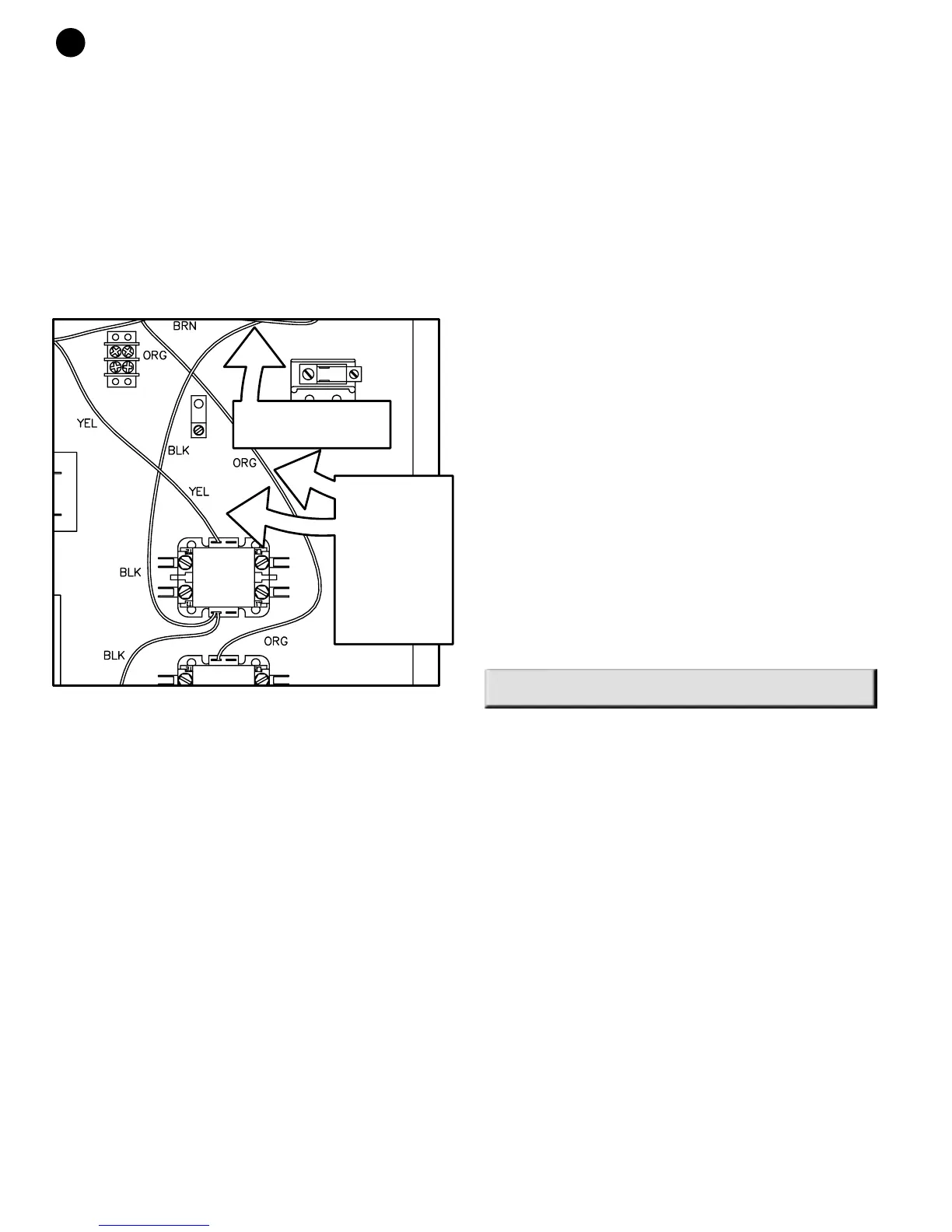

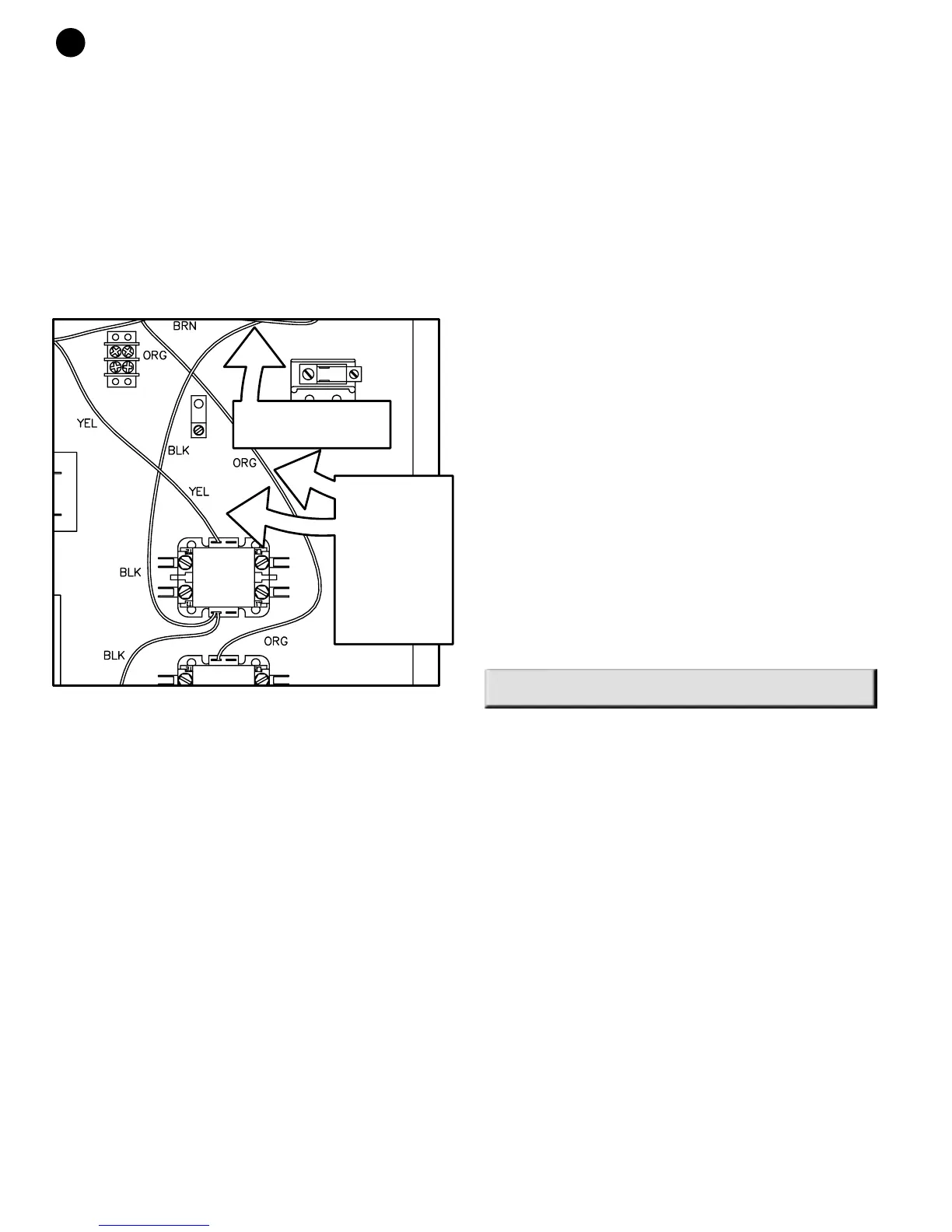

compressor contractor coil wires from CC1 to CC2 and

vice versa. Additionally the installer should set the time delay

relay to its minimum setting of 0.1 minutes to prevent

extended periods of the 40% compressor running alone with

full air flow. It is recommended that if the sequence of

operation is altered in this manner that the installer

replace the unit wiring diagram with the one shown in

Figure #18 to avoid confusion in the future.

The sequence of operation for this unit would basically be

the same as for a factory wired multi-step unit but with

the 60% compressor running in 1st stage and the 40%

compressor starting in 2nd followed immediately by the

60% compressor for full capacity.

WELL WATER SYSTEMS:

(Figure #11)

In well water applications water pressure must always be

maintained in the heat exchanger. This can be

accomplished with either control valve or a bladder type

expansion tank. When using a single water well to supply

both domestic water and the heat pump care must be

taken to insure that the well can provide sufficient flow for

both. In well water applications a slow closing solenoid

valve must be used to prevent water hammer.

Solenoid valves should be connected across Y1 and C1

on the interface board for multi-step units and Y2 and C1

for single step units. Make sure that the VA draw of the

valve does not exceed the contact rating of the

thermostat.

INSTALLATION OF PRESSURE

REGULATING VALVES:

Pressure regulating valves are used to increase or

decrease water flow through the heat pump in response

to refrigerant pressure. In some cases more water may

be required in heating than in cooling, or vice versa. With

the Geo-Miser heat pumps these valves are not required.

However, if installed, a pair of valves are required for

proper operation, one valve for cooling (direct acting) and

another valve for heating (indirect acting). A refrigerant

tap is provided in the refrigerant line located between the

reversing valve and the water-to-refrigerant heat

exchanger for proper monitoring of the refrigerant

pressures.

The discharge water from the heat pump is not

contaminated in any manner and can be disposed of in

various ways depending on local building codes (i.e.

discharge well, dry well, storm sewer, drain field, stream

or pond, etc.) Most local codes forbid the use of a

sanitary sewer for disposal. Consult your local building

and zoning department to insure compliance in your area.

COOLING TOWER/BOILER SYSTEMS:

(Figure #12)

The cooling tower and boiler water loop temperature is

usually maintained between 50˚ F to 100 ˚ F to assure

adequate cooling and heating performance.

In the cooling mode, heat is rejected from the FHP unit

into the water loop. A cooling tower provides evaporative

cooling to the loop water thus maintaining a constant

supply temperature to the unit. When utilizing open

cooling towers, chemical water treatment is mandatory to

ensure the water is free from corrosive elements. A

secondary heat exchanger (plate frame) between the unit

and the open cooling tower may also be used. It is

imperative that all air be eliminated from the closed loop

side of the heat exchanger to insure against fouling.

In the heating mode, heat is absorbed from the water

loop. A boiler can be utilized to maintain the loop at the

desired temperature.

CAUTION: Water piping exposed to extreme low

ambient temperatures is subject to freezing.

Consult the specification sheets for piping sizes. Teflon

tape sealer should be used when connecting to the unit

to insure against leaks and possible heat exchanger

fouling. Do not overtighten the connections. Flexible

hoses should be used between the unit and the rigid

system to avoid possible vibration. Ball valves should be

installed in the supply and return lines for unit isolation

and unit water flow balancing. Pressure/temperature

ports are recommended in both supply and return lines

for system flow balancing. Water flow can be accurately

set by measuring the water-to-refrigerant heat

exchangers water side pressure drop. See specification

sheets for water flow vs. pressure drop information.

Before final connection to the unit, the supply and return

hose kit must be connected together and the system

flushed to remove dirt, piping chips and other foreign

material. Failure to do so may cause poor unit

performance, heat exchanger damage and will void the

unit warranty.

EARTH COUPLED SYSTEMS:

(Figure #13)

Closed loop and pond applications require specialized

design knowledge.No attempt at these installations

should be made unless the dealer has received

specialized training. Utilizing FHP’s Ground Loop

Loading...

Loading...