5

GO SERIES

point for thermostat wiring, the interface board also

translates thermostat inputs into control commands for

the variable speed programmable ICM-2 DC fan motor

and displays an LED indication of operating status. The

thermostat connections and their functions are as

follows:

Y2 Second Stage Compressor Operation

Y1 First Stage Compressor Operation

G Fan

O Reversing Valve (energized in cooling)

W1 Auxiliary Electric Heat

(runs in conjunction with compressor)

EM/W2 Emergency Heat (electric heat only)

NC Transformer 24 VAC Common

(extra connection)

C1 Transformer 24 VAC Common

(primary connection)

R Transformer 24 VAC Hot

HUM Dehumidification Mode

(not used in GO Series)

If the Geo-Miser unit is being connected to a thermostat

with a malfunction light, this connection is made at the

unit lockout relay.

NOTE:: If the thermostat is provided with a malfunction

light powered off of the common (C) side of the

transformer (such as FHP’s part # 641-068), the unit

must be provided with a malfunction relay (FHP option #

660-006) to properly energize the light. The relay coil will

be wired across the (ALR) and (C) contacts on the unit’s

CCM board and the relay’s normally open contacts

across (ALR) and the malfunction light connection on the

thermostat. If the thermostat is provided with a

malfunction light powered off of the hot (R) side of the

transformer (such as FHP part#641-060), then the

thermostat malfunction light connection should be

connected directly to the (ALR) contact on the unit’s

CCM board.

To the left of the thermostat connection block are a row

of 2 red and 4 green LED’s. These LED’s indicate the

operating status of the unit. They are labeled as follows:

EM (red) Emergency Heat On

W1 (red) Auxiliary Heat On

O (green) Reversing Valve Energized, unit is in

cooling mode

Y2 (green) Second Stage Compressor On

Y1 (green) First Stage Compressor On

G (green) Fan On

Just above the connector block is a single red LED

labeled CFM that will blink intermittently when the unit is

running and may flicker when the unit is off. This LED

indicates the air delivery of the blower at any given time.

Each blink of the LED represent 100 CFM of air delivery

so if the LED blinks 12 times, pauses, blinks 12 times,

etc. the blower is delivering 1200 CFM. Refer to Figure

#7 for factory programmed air delivery settings for the

GO Series.

To the right of the thermostat connection block is a green

LED labeled dehumidify. This feature is not utilized on the

GO Series.

Just above and to the right of the thermostat connection

block are four sets of jumper pins labeled ADJ, DELAY,

HEAT and COOL. The ADJ set of pins are labeled NORM,

(+), (-) and TEST. GO units will all be set on the NORM

position from the factory, however, airflow can be

increased (+) or decreased (-) by 15% from the pre-

programmed setting by relocating the jumper in this

section. The TEST position is used to verify proper motor

operation. If a motor problem is suspected, move the

ADJ jumper to the TEST position and energize G on the

thermostat connection block. If the motor ramps up to

100% power, then the motor itself is functioning normally.

Always remember to replace the jumper to NORM, (+) or

(-) after testing and reset the unit thermostat to restore

normal operation.

NOTE: Do not set the ADJ jumper to the (-) setting when

electric heaters are installed. Doing so may cause the

heaters to cycle on their thermal overload switches,

potentially shortening the life of the switches.

The other three sets of jumper pins are used to select the

proper program in the ICM motor for the unit. Refer to

Figure #7 for the proper jumper placement.

NOTE: Always disconnect power before changing

jumper positions on the interface board and reset the unit

afterward.

To the left of the red and green status LED’s is a row of

1/4” male quick connects. These are used to pass

thermostat inputs on to the rest of the control circuit.

Remember to always turn off unit power at the circuit

breaker before attaching or disconnecting any wiring from

these connections to avoid accidental short circuits that

can damage unit control components.

SAFETY DEVICES AND THE LOCKOUT CIRCUIT:

Each Go Series unit is factory provided with a high

pressure switch, low pressure switch and a condensate

overflow switch. These switches are all normally closed,

opening on a fault condition. If either the high pressure

switch or the condensate overflow switch open, the unit

compressors will shut down immediately. Note that the

blower motor and electric heaters will remain active. The

low pressure switch is deactivated for 90 seconds after

compressor start-up by the low pressure bypass timer.

This prevents nuisance low pressure lockouts during cold

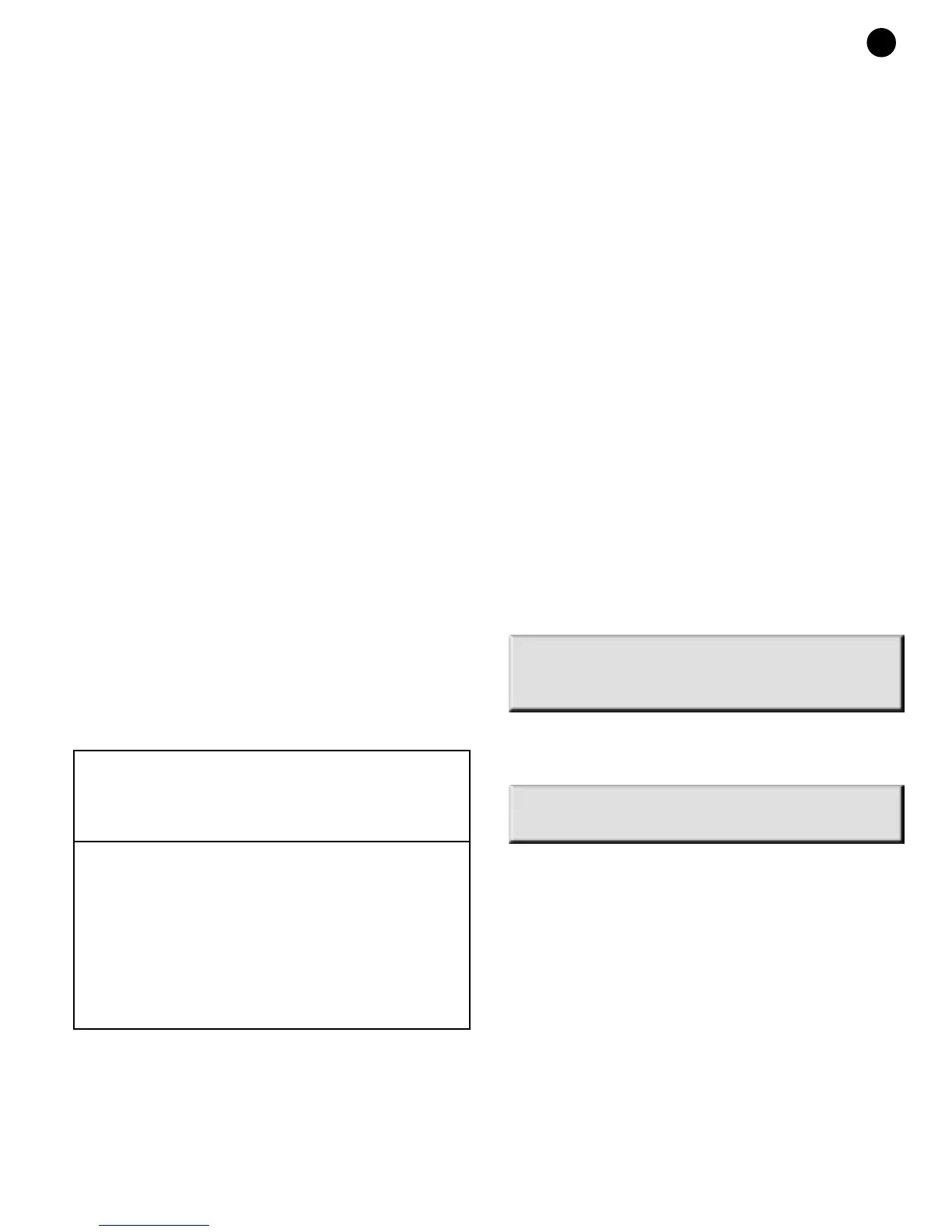

MOTOR PROFILE AIR FLOW TABLE

FAN LOW HIGH AUX. EMERGENCY COOL

MODEL ONLY STEP STEP HEAT HEAT HEAT

AIRFLOW DELAY ADJUST

GO024 550 – 800 900 900 B NORM

GO030 700 – 1000 900 900 A NORM

GO036 850 – 1200 1150 1150 A NORM

GO042 1000 – 1400 2000 2000 D NORM

GO048 1050 1100 1600 2000 2000 C NORM

GO060 1100 1400 2000 2000 2000 B NORM

GO072 1600 1600 2200 2200 2200 A NORM

(Figure #7)

Loading...

Loading...