pump. Plumbing connected to the heat pump must not

come in direct contact with joists, trusses, walls, etc..

Some applications require an attic floor installation of the

horizontal unit. In this case the unit should be set in a full

size secondary drain pan on top of a vibration absorbing

mesh. The secondary drain pan prevents possible

condensate overflow or water leakage damage to the

ceiling. The secondary drain pan is usually placed on a

plywood base isolated from the ceiling joists by additional

layers of vibration absorbing mesh. In both cases, a 3/4"

drain connected to this secondary pan should be run to

an eave at a location that will be noticeable. If the unit is

located in a crawl space, the bottom of the unit must be

at least 4" above grade to prevent flooding of the

electrical parts due to heavy rains.

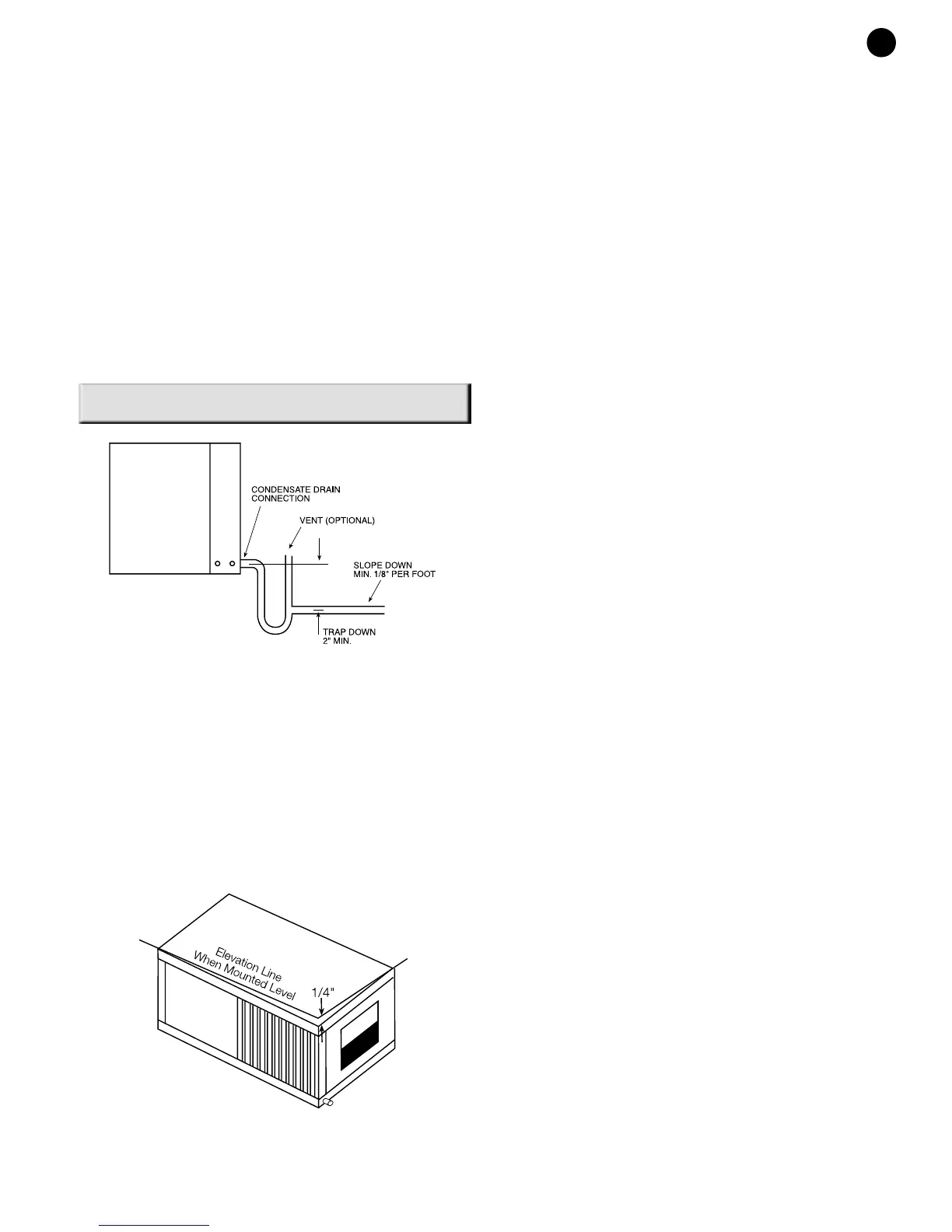

CONDENSATE DRAIN:

NOTE: If equipped with float style condensate overflow

switch, final adjustment must be made in the field.

All GO Units are equipped with a condensate overflow

sensor/switch. A drain line must be connected to the

heat pump and pitched away from the unit a minimum of

1/8" per foot to allow the condensate to flow away from

the unit.

This connection must be in conformance with local

plumbing codes. A trap must be installed in the

condensate line to insure free condensate flow. (Heat

Pumps are not internally trapped). A vertical air vent is

sometimes required to avoid air pockets. (See Figure #3).

The length of the trap depends on the amount of positive

or negative pressure on the drain pan. A second trap

must not be included.

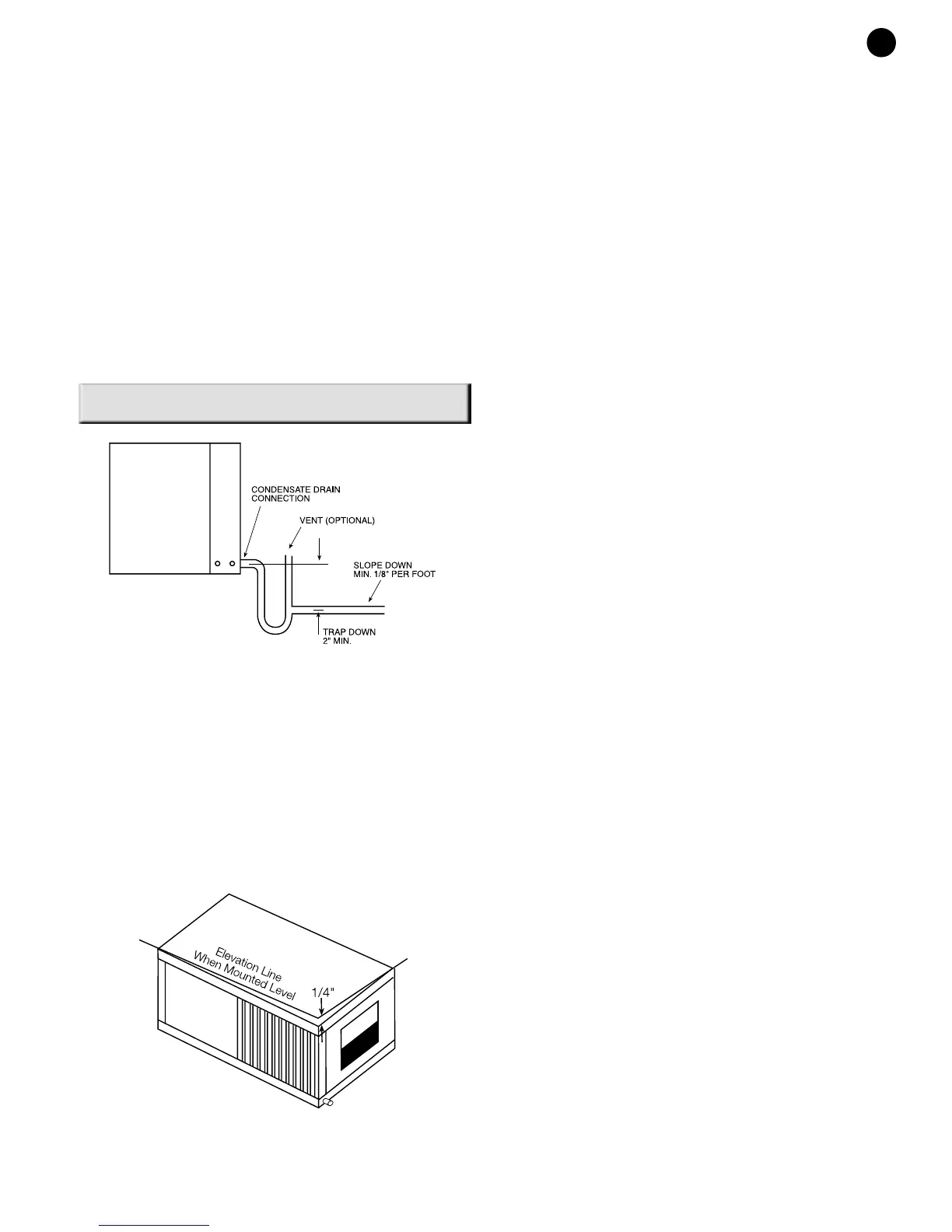

The horizontal unit should be pitched approximately 1/4"

towards the drain in both directions, to facilitate

condensate removal. (See Figure #4)

DUCT SYSTEM:

A supply air outlet collar and return air duct flange are

provided on all units to facilitate duct connections. Refer

to the FHP individual data specification sheet for physical

dimensions of the collar and flange.

A flexible connector is recommended for supply and

return air duct connections on metal duct systems. All

metal ducting should be insulated with a minimum of one

inch duct insulation to avoid heat loss or gain and prevent

condensate forming during the cooling operation.

Application of the unit to uninsulated duct work is not

recommended as the unit’s performance will be adversely

affected. Do not connect discharge ducts directly to the

blower outlet. The factory provided air filter must be

removed when using a filter back return air grill.The

factory filter should be left in place on a free return

system.

If the unit will be installed in a new installation which

includes new duct work, the installation should be

designed using current ASHRAE procedures for duct

sizing. If the unit is to be connected to existing ductwork,

a check should be made to assure that the duct system

has the capacity to handle the air required for the unit

application. If the duct system is too small, larger

ductwork should be installed. Check for existing leaks

and repair.

The duct system and all diffusers should be sized to

handle the designed air flow quietly. To maximize sound

attenuation of the unit blower, the supply and return air

plenums should be insulated. There should be no direct

straight air path thru the return air grille into the heat

pump. The return air inlet to the heat pump must have at

least one 90 degree turn away from the space return air

grille. If air noise or excessive air flow are a problem, the

blower speed can be changed to a lower speed to

reduce air flow. (Refer to ICM motor interface board

section in this manual and Figure #7)

PIPING:

Supply and return piping must be as large as the unit

connections on the heat pump (larger on long runs).

Never use flexible hoses of a smaller inside diameter than

that of the fluid connections on the unit. GT Units are

supplied with either a copper or optional cupro-nickel

condenser. Copper is adequate for ground water that is

not high in mineral content. Should your well driller

express concern regarding the quality of the well water

available or should any known hazards exist in your area,

we recommend proper testing to assure the well water

quality is suitable for use with water source equipment. In

conditions anticipating moderate scale formation or in

brackish water a cupro-nickel heat exchanger is

recommended.

Both the supply and discharge water lines will sweat if

subjects to low water temperature. These lines should be

insulated to prevent damage from condensation.

All manual flow valves used in the system must be ball

valves. Globe and gate valves must not be used due to

high pressure drop and poor throttling characteristics.

Never exceed the recommended water flow rates.

3

GO SERIES

(Figure #3)

(Figure #4)

Loading...

Loading...