- 24 -

- 25 -

Appendix I

Splice loss increase : Reason and solution.

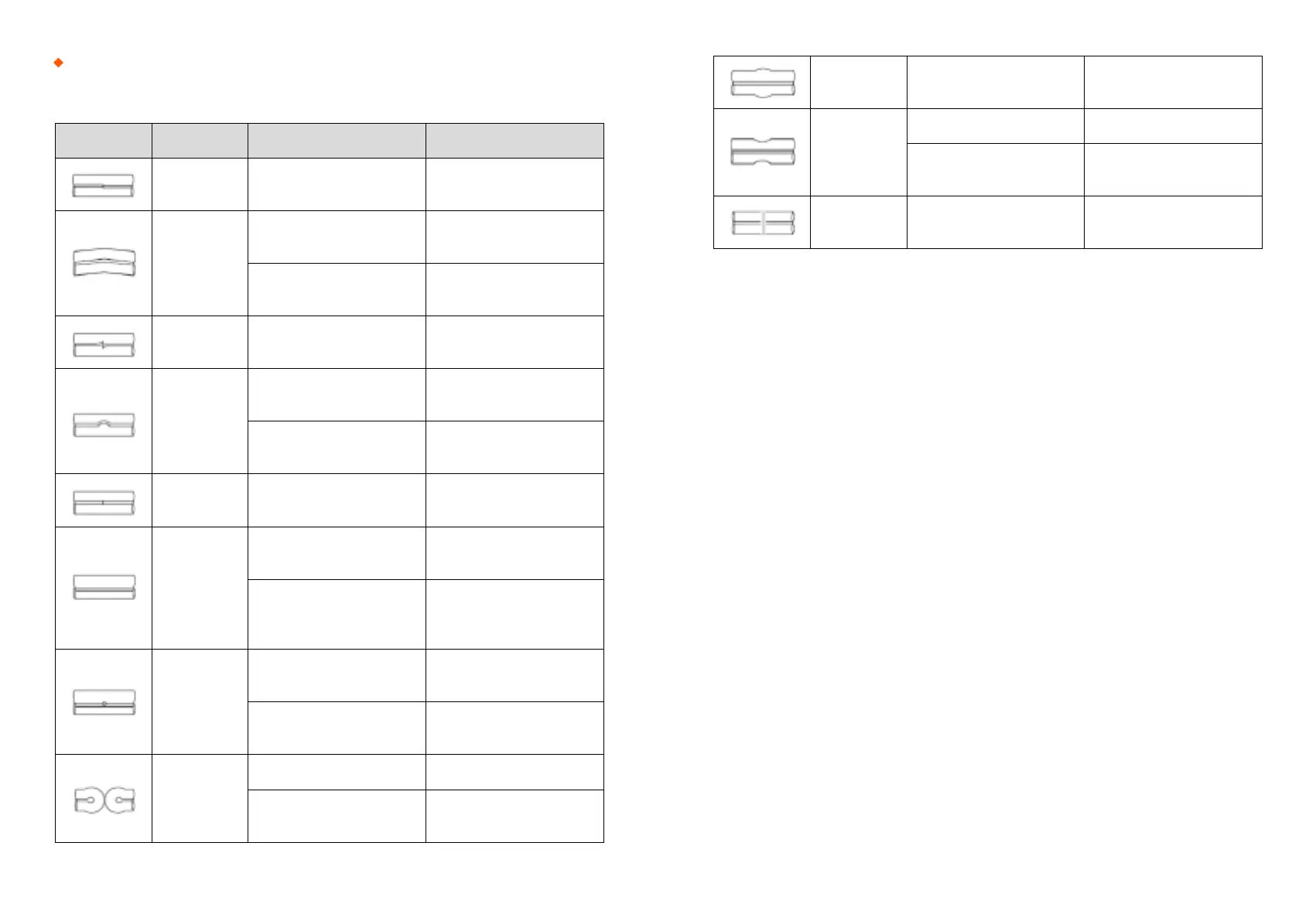

Symptom Name Reason Solution

Core Axial

Offset

Dust on v-groove or fiber

clamp chip

Clean v-groove and fiber

clamp chip

Core Angle

Dust on v-groove or fiber

clamp chip

Clean v-groove and fiber

clamp chip

Bad fiber end-face quality

Check if fiber cleaver is well

conditioned

Core Step

Dust on v-groove of fiber

clamp chip

Clean v-groove and fiber

clamp chip

Core Curve

Bad fiber end-face quality

Check if fiber cleaver is well

conditioned

Pre-fuse power too low or

pre-fuse time too short

INcrease [Pre-fuse power]

and/or [Pre-fuse time]

MFD

Mismatch

Arc power too low Increase [Arc power]

Combution

Bad fiber end-face quality Check the cleaver

Dust still present after

cleaning fiber of cleaning

arc

Clean fiber throughly or in-

crease [Cleaning arc time]

Bubbles

Bad fiber end-face quality

Check if fiber cleaver is well

conditioned

Pre-fuse power too low or

pre-fuse time too short

Pre-fuse power too low or

pre-fuse time too short

Separation

Fiber stuffing too small Perform [Motor calibration]

Pre-fuse power too high of

pre-fuse time too long

Decrease [Pre-fuse power]

and/or [Pre-fuse time]

Note : A vertical line sometimes appears at the splice point when MM fibers, or dissimilar fibers (different diam-

eters) are spliced. This does not affect splice quality, such as splice loss or tensile strength.

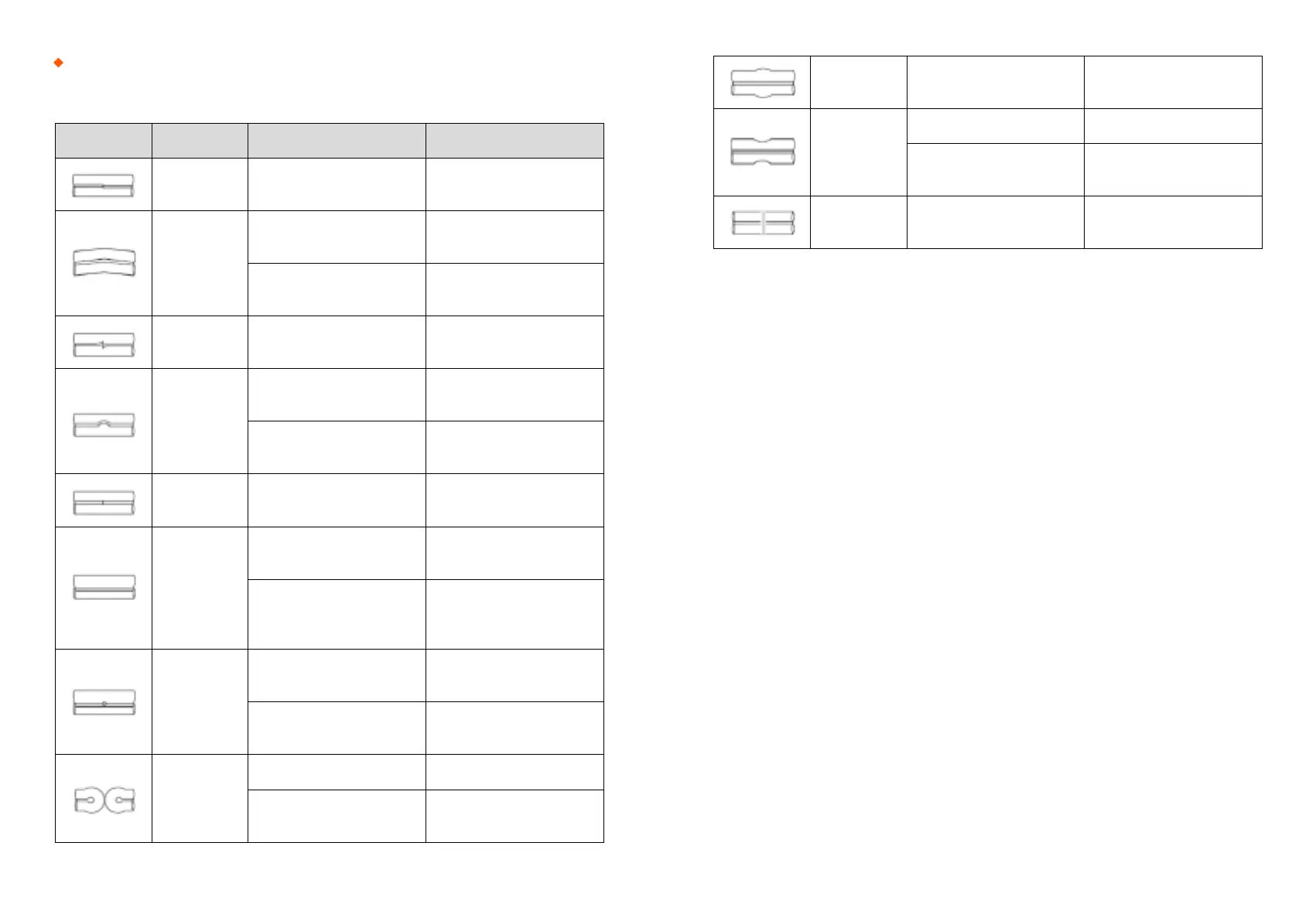

Fat Fiber stuffing too much

Decrease [Overlap] and

perform [Motor clibration]

Thin

Arc power not adequate Perform [Arc calibration]

Some arc parameters not

adequate

Adjust [Prefuse power],

[Pre-fuse time] or [Overlap]

Line

Some arc parameters not

adequate

Adjust [Prefuse power],

[Pre-fuse time] or [Overlap]

Loading...

Loading...