- 28 -

- 29 -

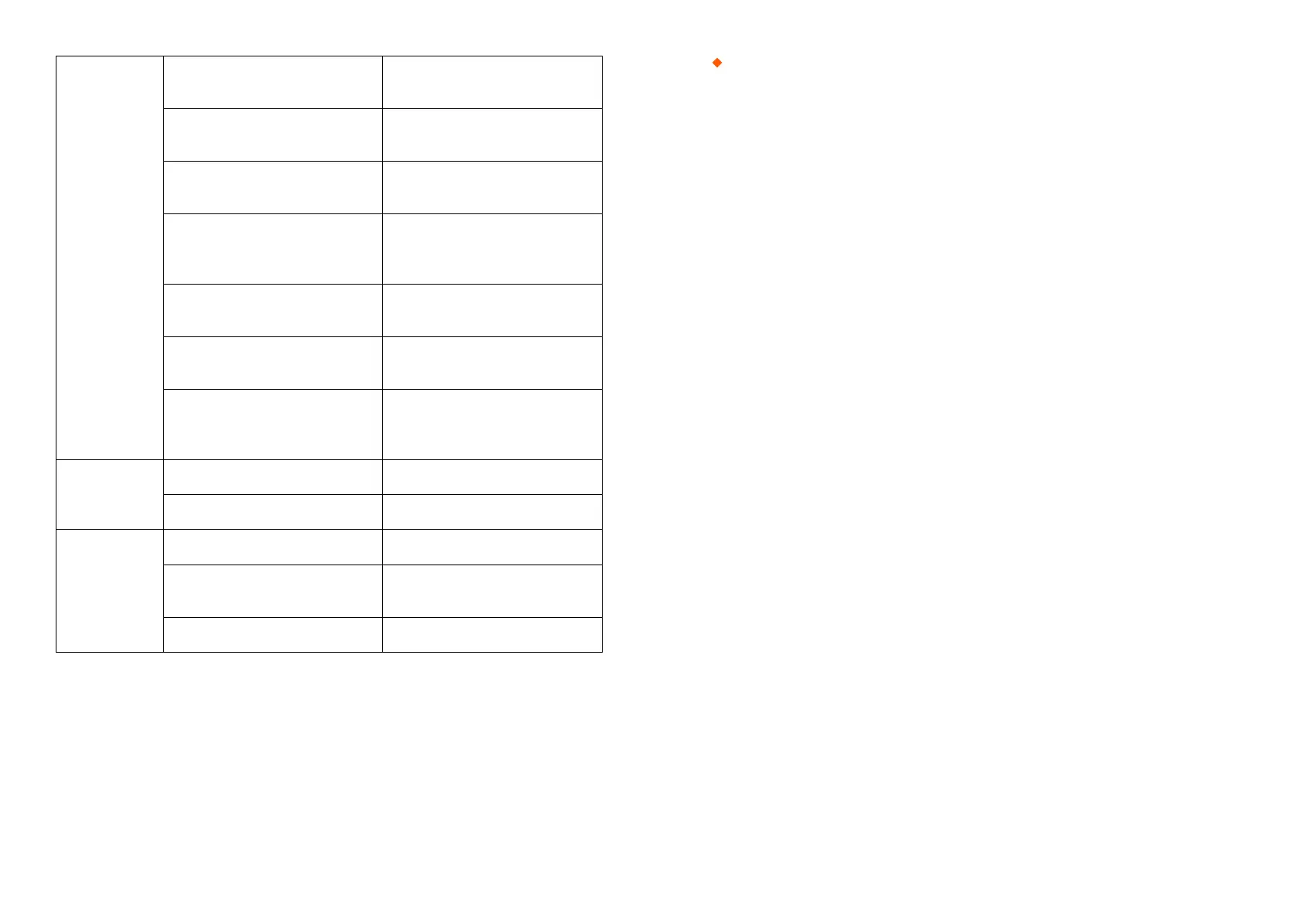

Dust Error

(fiber core)

There’s dust or dirt on the fiber

surface

Prepare the fiber again

The lens or LEDs are coated in

dust

Execute the dust check after

cleaning the lenses and LEDs

Cleaning Arc time is too short

Set the cleaning arc time to be

180ms

It is difficult to identify the fiber

core by using the method of core

alignment to splice

It is difficult to identify the fiber

core by using MM splice mode to

splice

There’s dust or dirt on the fiber

surface

Prepare the fiber again

There’s dust or dirt on the fiber

surface

Execute the [Dust check] after the

lenses and LEDs are cleaned

Cleave angle limit is too low

Increase the cleave angle limit to

a decent value

(standard value: 3.0˚c)

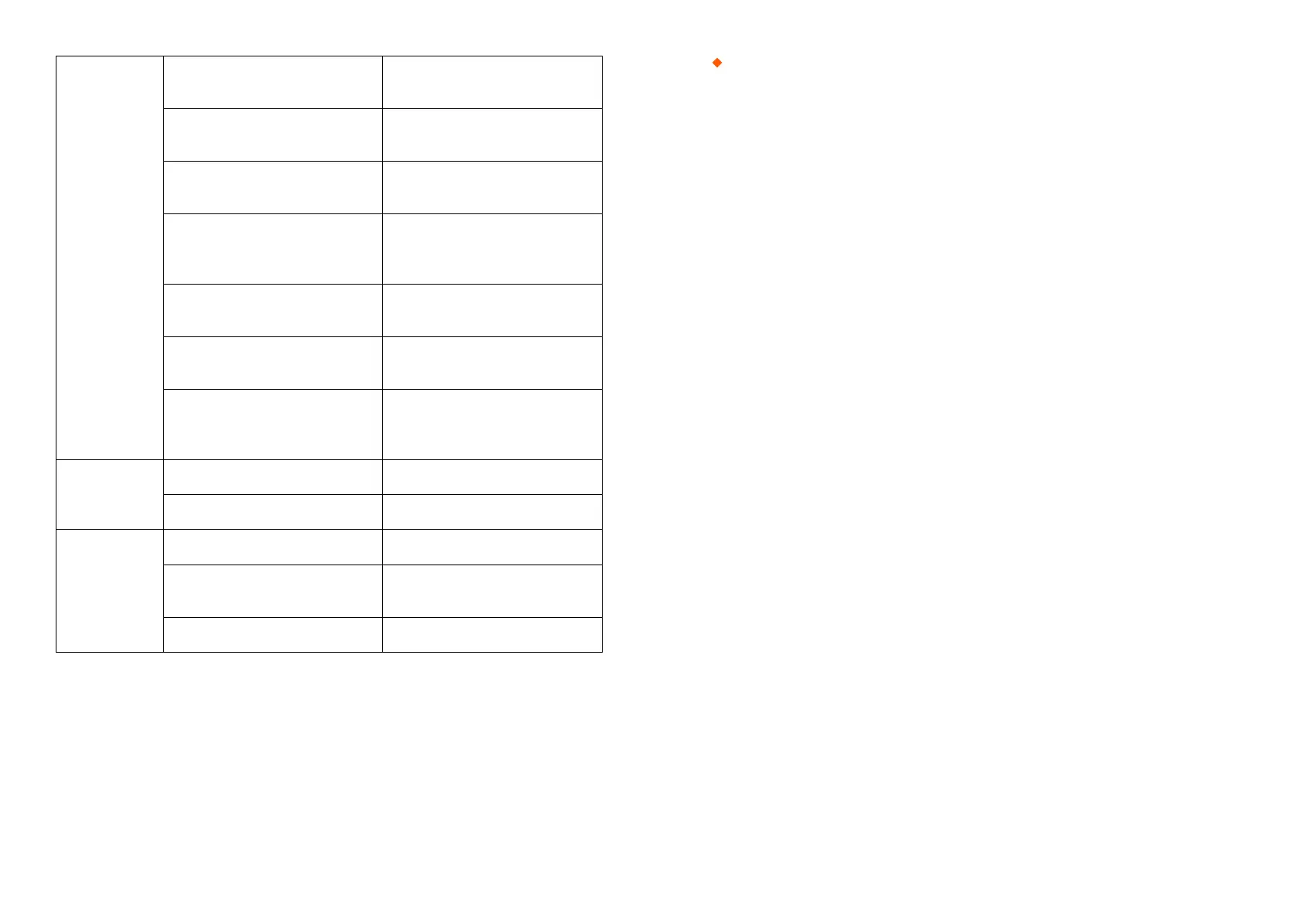

Fat Fiber

Overlap too much Adjust overlap parameter

Motor is not calibrated Calibrate and maintain the motor

Thin Fiber

Arc power too low Execute [Arc Calibration]

The level of pre-discharge is too

high

Decreased pre-discharge of

pre-discharge time

Insufficient overlap Adjust overlap parameter

Appendix III

· Power does not turn off when pressing On / Off button.

Press and hold the key until the LED color changes from green to red.

· Few splices can be made with a fully charged battery pack

· If the power saving function is not enabled, battery power degrades quicker.

[System setting] Always enable it to conserve power usage.

· If degradation appears (memory effect). of if the battery pack is stored for an extended period of

time, complitely discharge it. After discharge completion, recharge the battery pack.

· The battery pack has reached the end of its service life. Install a new battery pack.

· The battery pack uses chemical reaction. The capacity decreases at low temperature, especially at

lower than 0 degree

˚c.

·

Error message appears on monitor please refer to appendix II.

·

Inconsistent splice loss / High splice loss

·

Clean the V-grooves, fiber clamps, wind protector mirrors, and objective lenses.

·

Replace the electrodes.

·

Please refer to Appendix I.

·

The splice loss varies according to the cleave angle, arc conditions and fiber cleanliness.

·

Monitor suddenly turned off

·

The monitor suddenly turn off after an extended period of splicer inactivity, if the power

saving function is enabled. Press any key to return to the normal state.

·

Splicer power suddenly turned off without “Low battery’ message.

·

The monitor will turn off after an extended period of splicer inactivity, if the power saving

function is enabled. Press ant key to return to the normal state.

·

Identify fibers error in AUTO mode

AUTO mode is applicable for SM, MM, NZ fiber. Errors may occurs while splicing special

fibers.

· Mismatch between Estimated splice loss and Actual splice loss

· The estimated loss is a calculated loss, so it can be used for reference only.

· The optical components of the splicer may need to be cleaned.

· Fiber protection sleeve does not shrink completely.

· Extend the heating time.

· Method to cancer heating process.

· Press Heat key to srop during heating process. The LED light will go off after pressing.

[Questions and troubleshooting]

Loading...

Loading...