Doc. P/N 8.8517.00.6

Rev. December, 2019

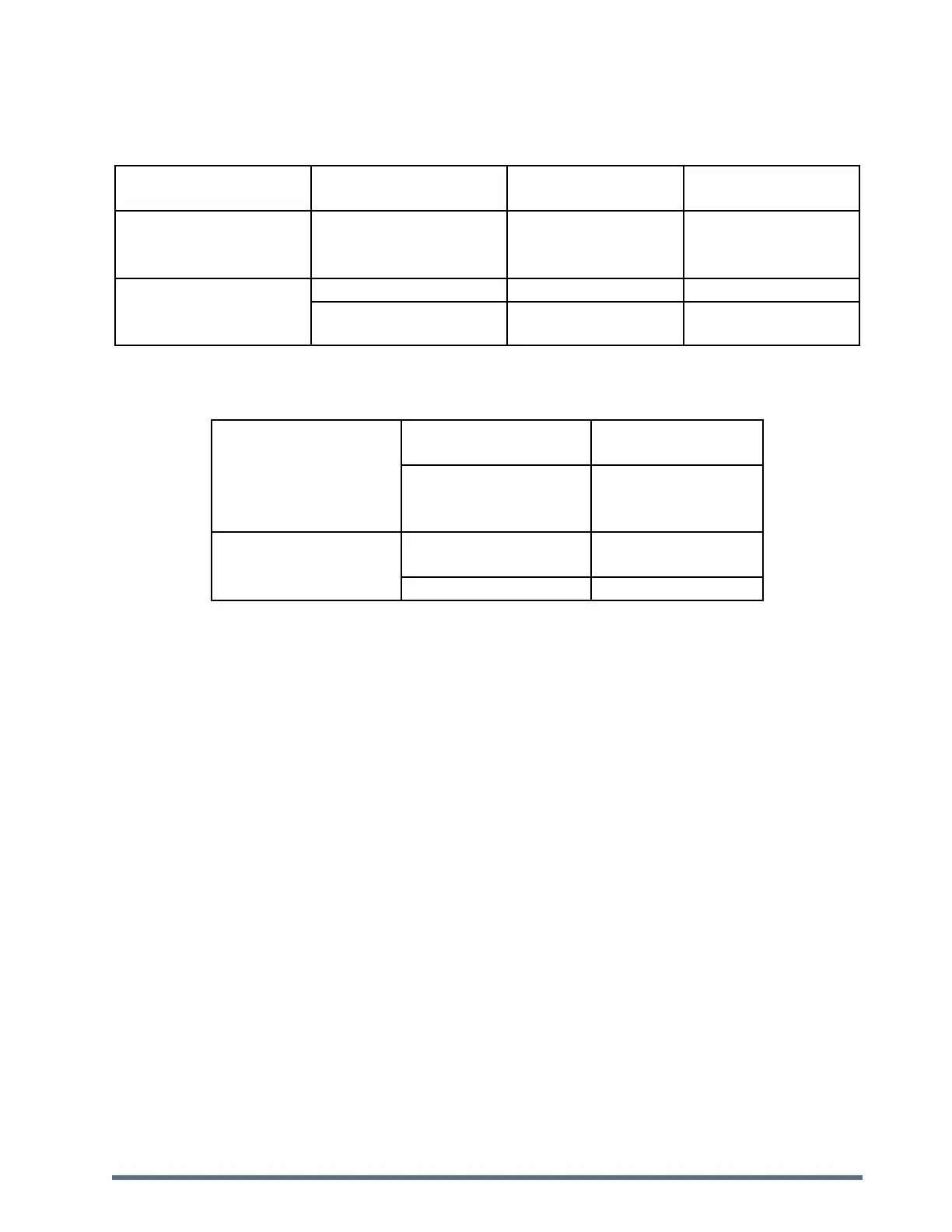

1.3. Clarification of the Temperature Classes

1.3.1. ATEX

Maximum process

temperature

Part of the equipment

situated in Category 1

(zone 0/20)

T 85 °C

T 100 °C

T 130 °C

Part of the equipment

situated in Category 2

(zone 1/21)

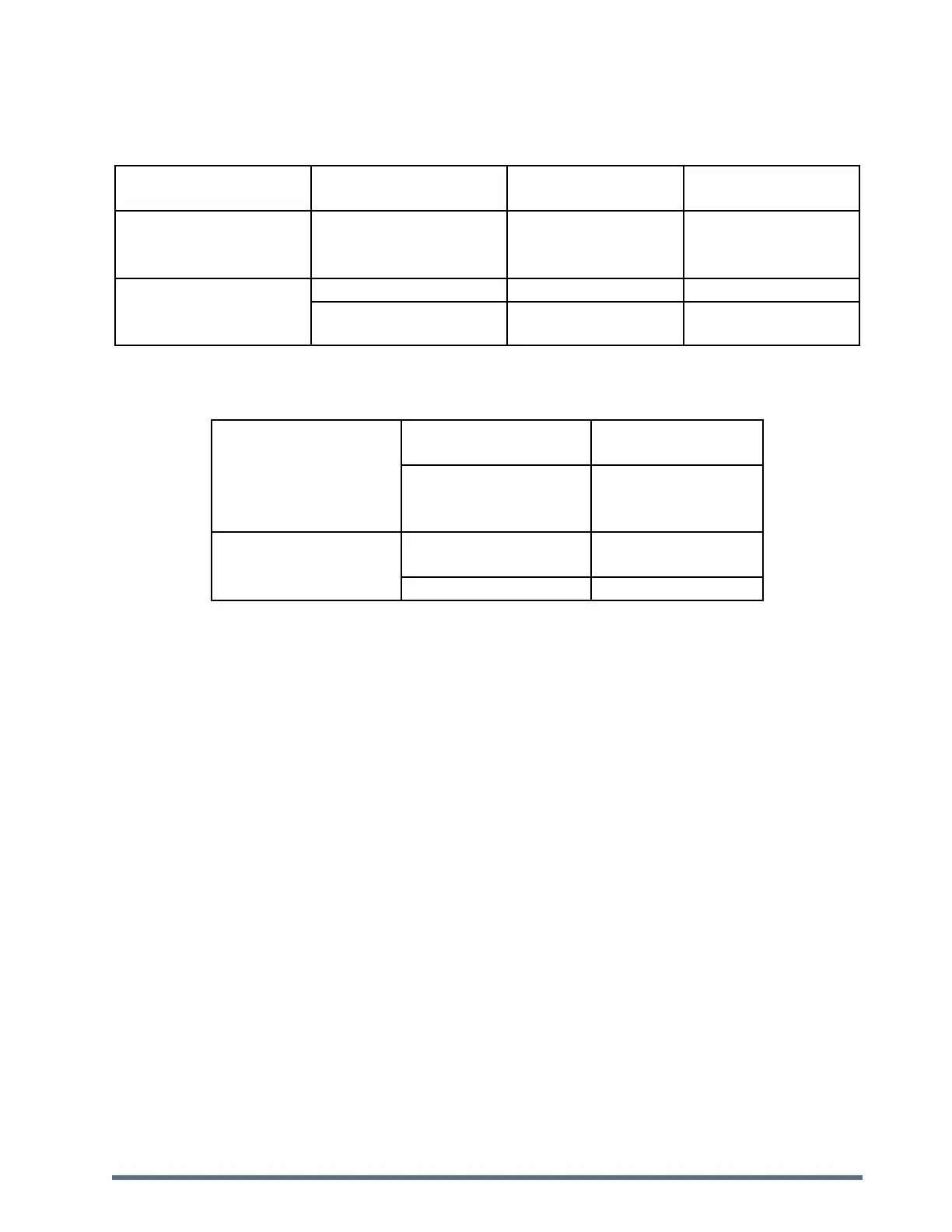

1.3.2. IECEx

Part of the equipment

situated in zone 20

Maximum process

temperature

T 85 °C

T 100 °C

T 135 °C

Part of the equipment

situated in zone 21

Maximum ambient

temperature

1.4. Hazardous Area Information

1.4.1. Cerex (D) – Explosion Protection Ceramic Pressure Detector ‘Dust’

This detector is suitable for installation in:

Dust Ex areas: installation into zone 21 (and 22) and wetted parts in contact with zone 20.

1.4.2. Cerex (G/D) – Explosion Protection Ceramic Pressure Detector ‘Gas’

This detector is suitable for installation in:

Dust Ex areas: installation into zone 21 (and 22) and wetted parts in contact with zone 20

Gas Ex areas: installation into zone 1 (and 2) and wetted parts in contact with zone 0.

When installed in Gas Ex zones, an Eex(i) intrinsic safe separation barrier shall be used (installed in an non-

hazardous area, typically in Fike EPACO enclosures).

1.4.3. Conditions for Special Use

For the equipment with a permanently connected cable, the user will have to connect the free extremity of cable

either in a non-explosive atmosphere, or in an enclosure protected by a recognized protection mode adapted to the

area.

Loading...

Loading...