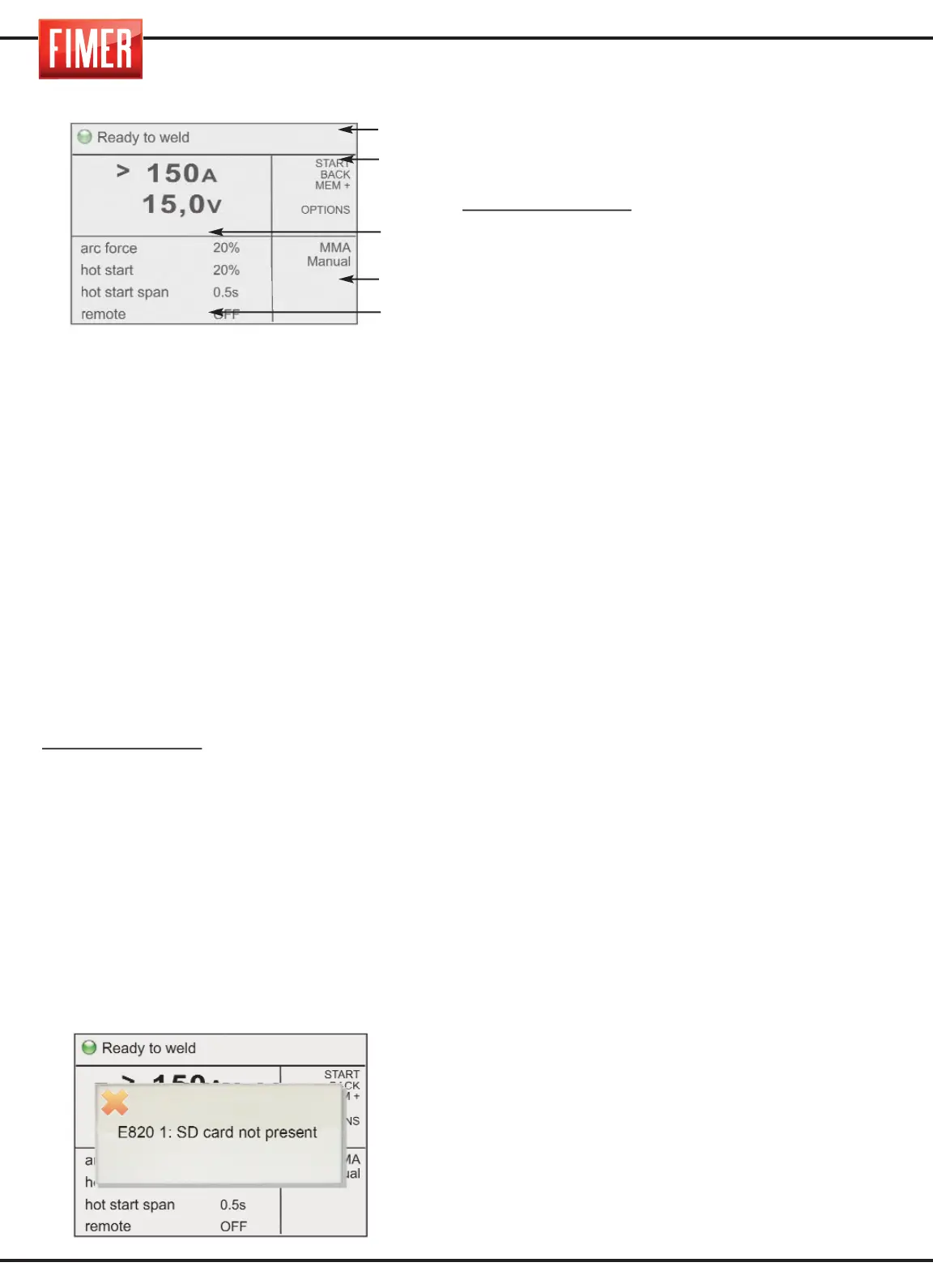

FIGURE 1:

1. Graphic display:

The 5,7’’ colour screen displays different

screens, according to the welding mode or

settings. In weld mode the display is divided

into five principal:

Part 1: Machine status

Part 2: Meaning of the active buttons

(buttons 2, 3, 4, 5,6 di fig.1)

Part 3: Size values set

Part 4: Type of process selected

Part 5: Indicates the values that can be set

for the various welding settings (to change

the values select using switch 10 and

confirm the selection by pressing the same

switch; the value will be highlighted in a

contrasting colour. The values can be

changed by turning the switch, to confirm

the new value press the switch again. 10).

Highlighted value:

Indicates the parameter

that is being changed using switch 10.

DISPLAYS:

- When the screen comes on, the Fimer logo

will appear and the Firmware revisions will load.

CONTROL BUTTONS:

(2, 3, 4, 5,6 in fig.1)

Each control button is associated with a

specific function shown on the display.

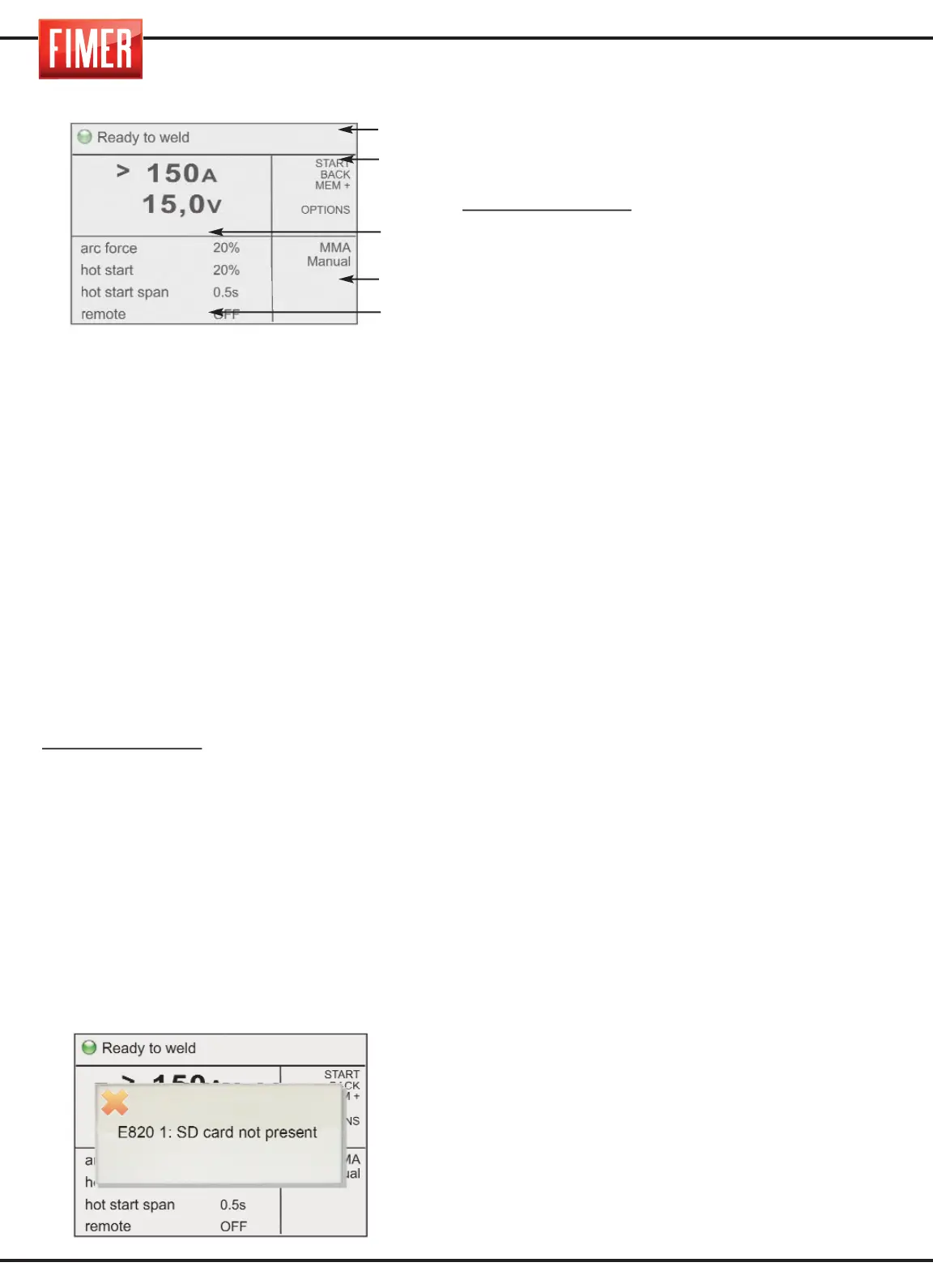

7. SD slot: this slot, covered with a rubber

cap, contains the SD-Card provided with the

machine; without the card, the machine will

be inactive and a warning message will

appear on the screen.

8. USB port: for technical assistance only.

9. Switch for adjusting the principal

welding settings: This switch is used to

set the principal welding parameters:

MMA/TIG Welding;

set the welding current

11. H²O in: to be used only with liquid coo-

ling torches.

12. H²O out: to be used only with liquid coo-

ling torches.

13. Connector for remote control of the current.

14. Front inlet “+”: hold positive.

MMA Mode: Electrode holder

15. EUROCONNECTOR (SEPARATED

TROLLEY): quick connector for welding torch.

This connector is used to supply welding

gas to the torch, the electrical contacts of the

torch button and the welding current.

16. ON-OFF SWITCH: turns the machine on

and off.

KING 510 machine is equipped by

hydromagnetic for this purpose, as showed in

fig. 16a.

17. Front inlet “-”: hold negative

MMA Mode: Ground clamp

TIG Mode: TIG Torch

MIG Mode with gaz: Ground clamp

MIG Mode without gaz: Ground clamp

18. Front inlet “+”: hold positive.

Modalità MMA: Electrode holder

Modalità TIG: Ground clamp

MIG Mode with gaz Not used

MIG Mode without gaz: Not used

19. TIG gas Outlet

20. MIG signal connector: Connection of

the signals to the push-pull torch

21. Filling cap of the cooling liquid

(Optional) (Cooling unit)

22. H²O in: To be used only with liquid coo-

ling torches.

23. AIR GRILL

24. ON-OFF switch and light of the con-

trol unit (Option): This lights up when the

cooling system is fed.

Parte 1

Parte 2

Parte 3

Parte 4

Parte 5

6

Loading...

Loading...