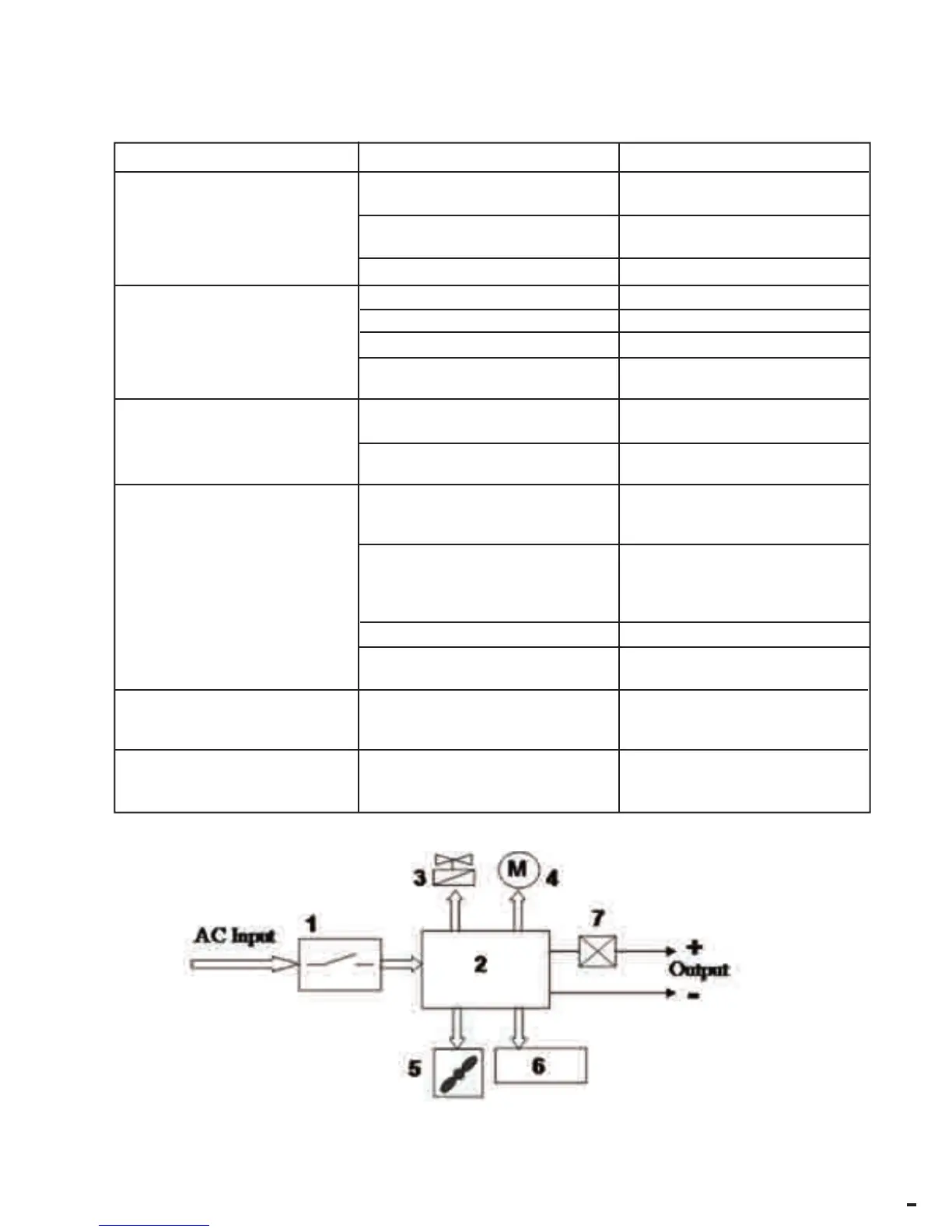

10. TROUBLE SHOOTING

The most common problems and their solutions are listed below:

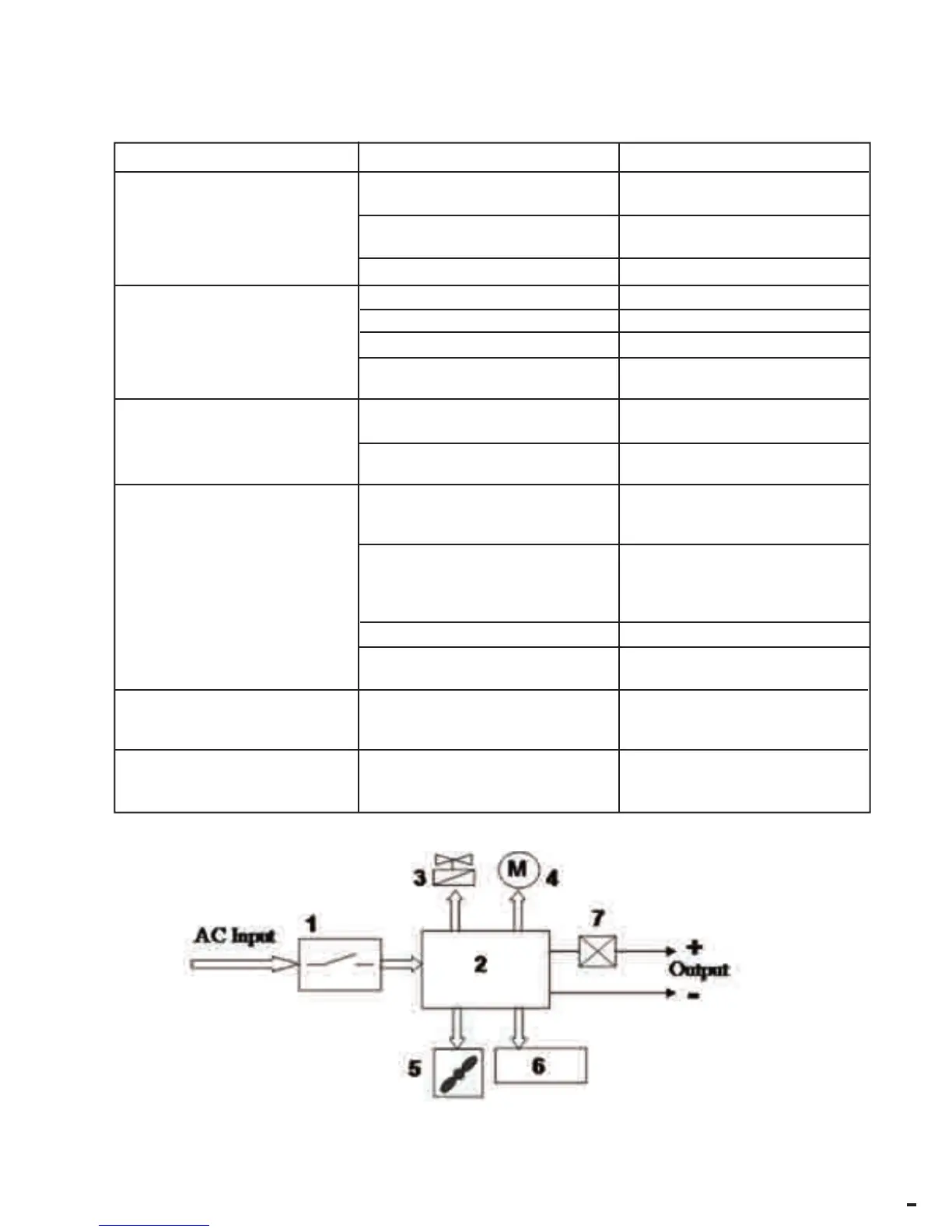

11. BLOCK DIAGRAM

DEFECT

CAUSE

SOLUTION

The wire does not feed when

the wire-feeder roller rotates

Jerky or intermittent wire-

feed.

Arc cut-out

Porous welds

Dirt on the tip of the wire-feeder

Blow with compressed air,

replace nozzle

Excessive spool torque.

Loose

Faulty torch.

Check wire-feeder liner.

Faulty gas nozzle.

Replace.

Scorched gas nozzle.

Replace.

Dirt in wire-feeder roller groove.

Clean.

Worn wire-feeder roller groove

Replace.

Earth clamp not secured to

workpiece..

Tighten clamp grip

Short circuit between contact

nozzle and gas hose.

Lack of shielding gas caused by

build-up in gas nozzle

Torch angle or torch-workpie-

ce gap incorrect.

Gas shortage

Damp workpieces

Clean away build-up

The air gap between the torch

and the workpiece must be 5-10

mm. Ensure 60° torch angle.

Increase gas flow

Dry workpieces with hot-air

gun or suchlike

Unit overheated and thermal pro-

tection device has set in

Welder cuts out after prolonged

use

Leave the unit to cool down for

at least 20-30 minutes.

Insufficient mains voltage.

The welder cuts out and E.Ln

appears on display panel

Check extension cable is not too

long and/or of an inappropriate

cross-section.

Clean or replace contact nozz-

le and wire-feed nozzle

1 Input Switch

2 Control and power card

3 Solenoid Valve

4 Wire-feeder motor

5 FAN

6 Display panel

7 Current sensor (installed on block 2)

Loading...

Loading...