Page 16 of 28

®

DUAL

Integrated Fire Protection System

OWNER'S OPERATION & MAINTENANCE MANUAL

FM-0860-0-31F

5. PREACTION AIR SUPPLIES

The sprinklers network of the preaction system uses air

pressure for supervisory purposes. The air supply can be

provided with either internal or external supervised air

supplies.

Two (2) styles of air supplies are available for the

FIREFLEX

®

DUAL unit depending on needs or

configurations. These air supplies are all factory assembled,

mounted in the cabinet and pressure tested. They are all

located in the top part of the cabinet, hung on mounting rails

above the valve trim. Here is the description of those

options:

♦ Air supply Style "A"

See figure 5.3.

Used only for the sprinkler piping network of the preaction

system. Air supply Style "A" includes the air compressor

mounted inside the

FIREFLEX

®

DUAL cabinet with its

supervisory trim and options. Compressor is factory piped

to the sprinkler piping system riser. It is available in three (3)

sizes:

1/6HP

1/3HP

1/2HP

All the above air compressors are oiless piston type without

reservoir and have open, single phase motor with internal

thermal protection and supply voltage of 120Vac, 60Hz or

220Vac, 50/60Hz.

♦ Air supply Style "B"

See figure 5.4.

Used only for the sprinkler piping network of the preaction

system, when an external air supply is provided by others

(either a compressor, plant air or dry nitrogen cylinders) and

piped to the air inlet port of the unit. Air supply Style "B"

provides an air pressure maintenance device (APMD) (E5)

trim, factory mounted in the

FIREFLEX

®

DUAL cabinet.

Note: When air supplies Style "B" is selected, the air

supply should be provided and installed by the sprinkler

contractor OUTSIDE of the FIREFLEX

®

DUAL cabinet.

It IS NOT provided with the unit.

5.1 AIR SUPPLY DESIGN AND SELECTION

The air supply compressor should be sized to automatically

establish the total required air pressure in 30 minutes.

External air supply should be provided with an air pressure

maintenance device (air supply Style "B") to regulate and

restrict the flow of supervisory air into the sprinkler system

piping.

WARNING ! Pressures other than the factory pressure

settings may affect the operation of the system.

Note: Selection of the proper air compressor size is the

responsibility of the installing contractor.

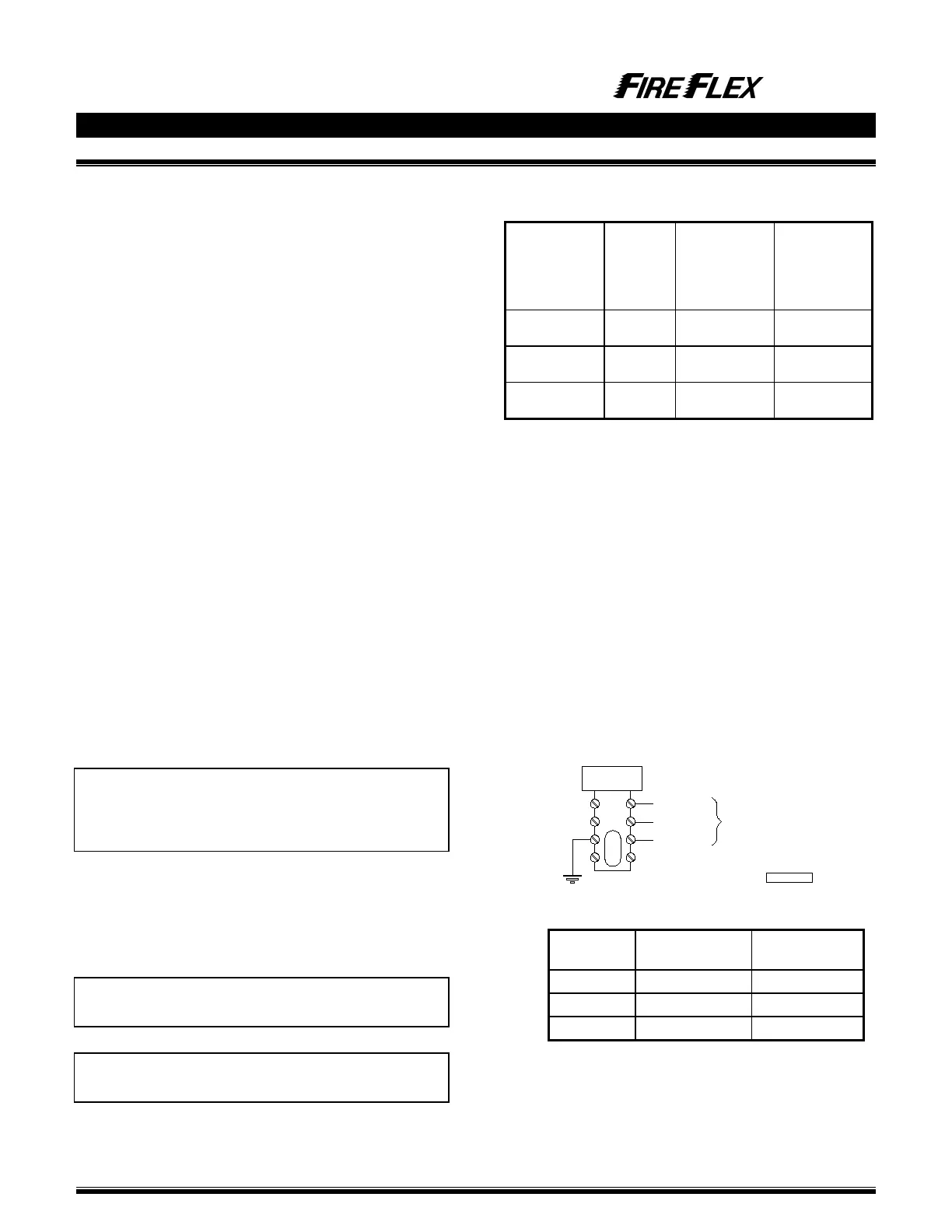

Table 5.1 - Compressor selection

Compressor

size

CFM

@

40 psi

120VAC

System

capacity

to pump 40 psi

in 30 minutes

220VAC

System

capacity

to pump 40 psi

in 30 minutes

1/6 HP

1.33

CFM

110 gallons 90 gallons

1/3 HP

2.61

CFM

215 gallons 170 gallons

1/2 HP

4.06

CFM

335 gallons 270 gallons

5.2 Air compressor AC power connection

(Air supply Style "A" only)

The motor must be protected against short circuit, overload

and excessive temperature rise. Fuses, motor protective

switches and thermal protective switches provide the

necessary protection in these circumstances.

Fuses only serve as a short circuit protection of the motor

(wiring fault), not as protection against overload. Those are

provided and wired by the electrical contractor.

An isolation switch (E15) is also provided in the

FIREFLEX

®

DUAL cabinet (see figure 6.2) and is factory

wired, allowing powering off the air compressor while some

maintenance work on the unit is done, without disturbing the

rest of the system.

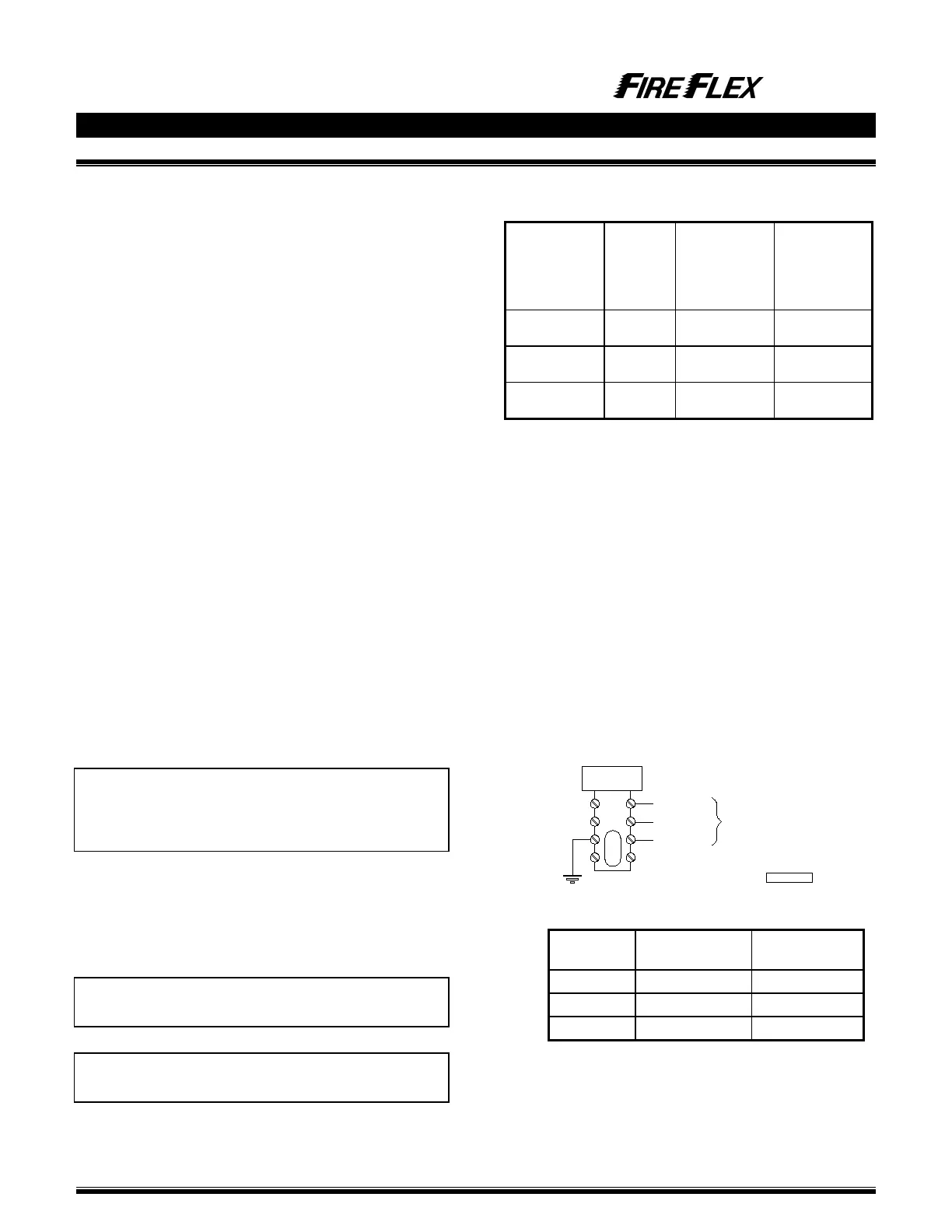

Connect non-energized AC power to the air compressor

input circuit (see figure 5.1).

Figure 5.1 - Wiring of power source

Table 5.1 - Compressor Amp rating

size

120VAC, 60Hz

220VAC, 50/60Hz

1/6 HP 6.6 A 3.3 A

1/3 HP 6.6 A 3.3 A

1/2 HP 8 A 4 A

NEUTRAL

GROUND

LINE

AC POWER SOURCE INPUT

4

3

2

1

TBB

AIR COMPRESSOR

120 / 220VAC

1/2 HP MAX

FM-076Z-0-7A

Loading...

Loading...