Page 2 Brief Guide FMP10 / FMP20

Areas of Application

2 Areas of Application

The instrument is used for coating thickness measurements.

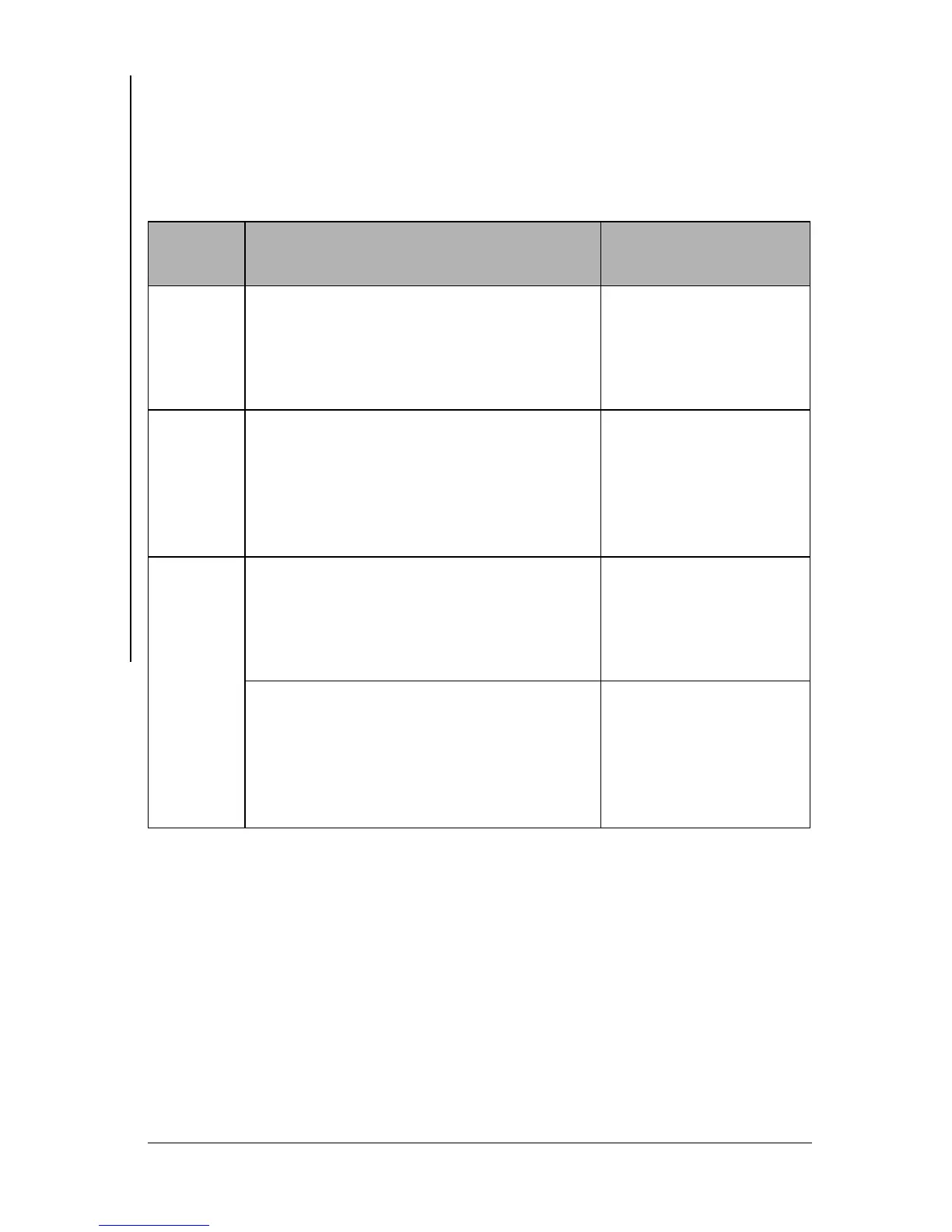

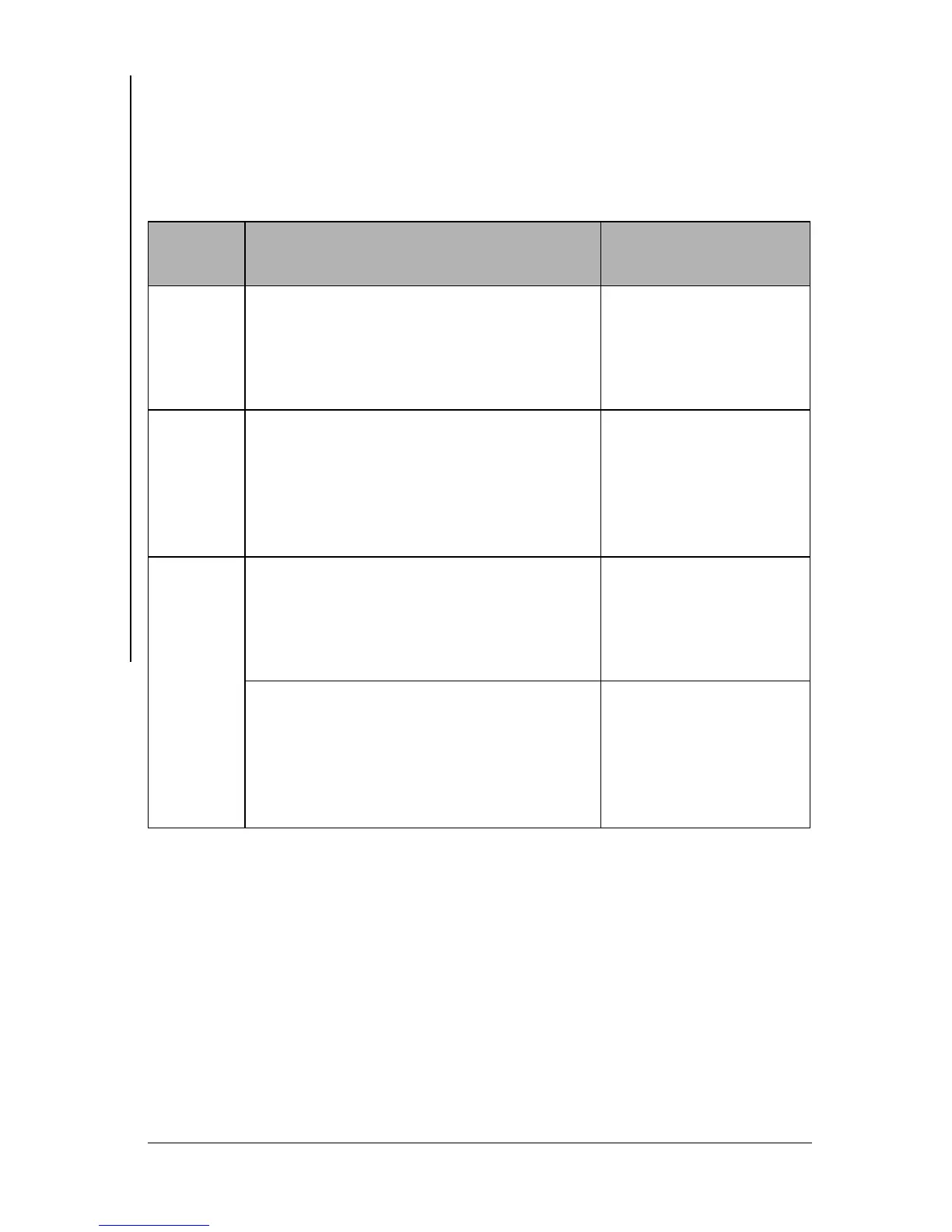

The following table lists the measurement methods that are used in the various

FMP instruments.

The instrument has the capability of setting up up to 1000 readings to save.

Instrument Area of application

Measurement method /

Probe type

DELTA-

SCOPE

Determination of the thickness of non-magnetic

coatings on steel or iron. E.g, chrome, copper, zinc

as well as paint, lacquer, enamel or plastic coat-

ings on steel or iron.

Magnetic Induction Method

According to DIN EN ISO

2178.

Probe: e.g., FGAB1.3

ISO-

SCOPE

Determination of the thickness of electrically non-

conducting, non-magnetic coatings on non-ferro-

magnetic electrically conducting base materials.

Paint, lacquer or plastic coatings on, for example,

aluminum, copper, zinc, etc. as well as anodized

coatings on aluminum.

Amplitude-Sensitive Eddy

Current Method According to

DIN EN ISO 2360.

Probe: e.g., FTA3.3

DUALSCOPE

Determination of the thickness of non-magnetic

coatings on steel or iron. E.g, chrome, copper, zinc

as well as paint, lacquer, enamel or plastic coat-

ings.

Magnetic Induction Method

According to DIN EN ISO

2178.

Probe: e.g., FD10

Determination of the thickness of electrically non-

conducting, non-magnetic coatings on non-ferro-

magnetic electrically conducting base materials.

Paint, lacquer or plastic coatings on, for example,

aluminum, copper, zinc, etc. as well as anodized

coatings on aluminum.

Amplitude-Sensitive Eddy

Current Method According to

DIN EN ISO 2360.

Probe: e.g., FD10

Loading...

Loading...