Type 2500

13

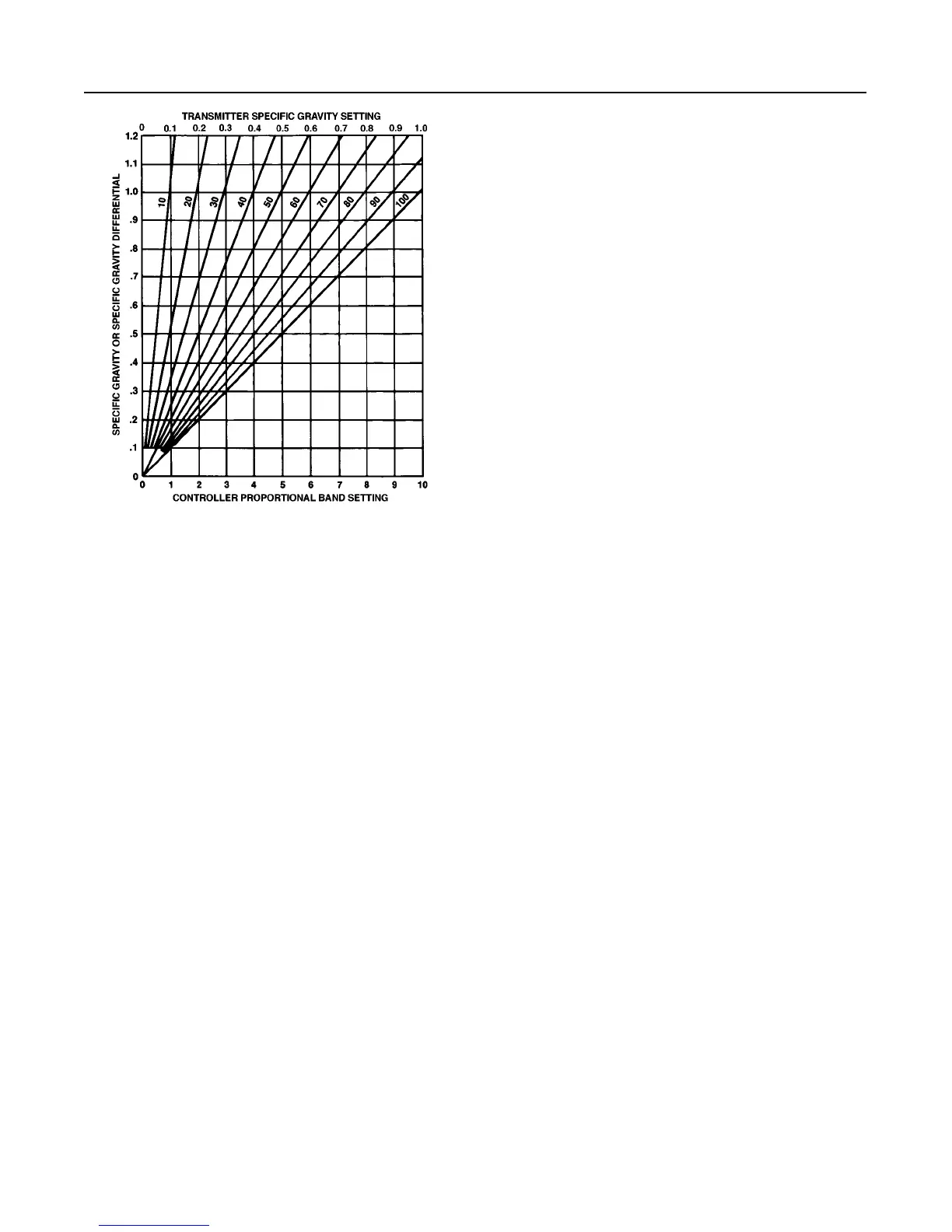

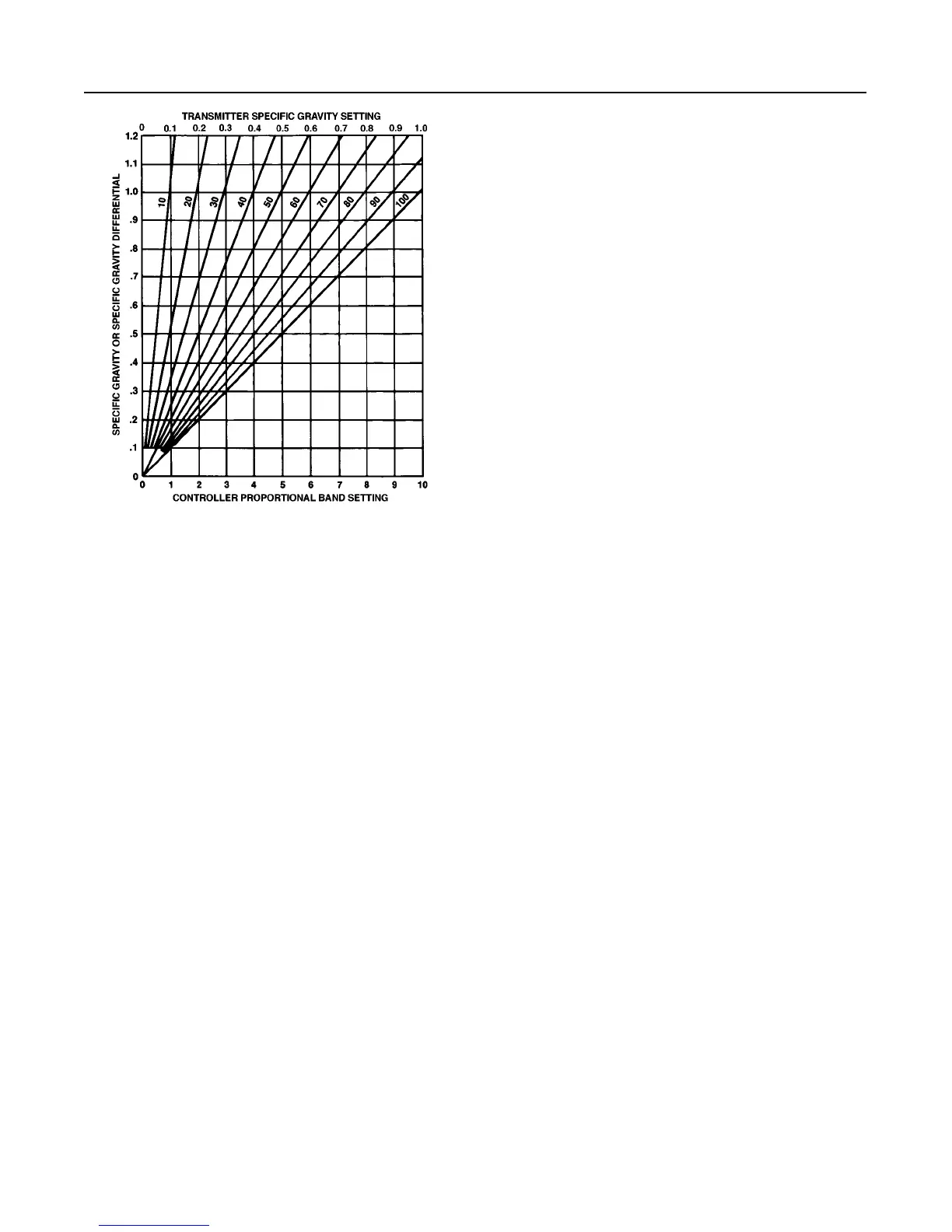

Figure 13. Proportional Band and Specific Gravity

Setting Chart (chart assumes standard wall torque tube and

displacer volume in table 2)

NOTE:

EACH CURVE MARKED WITH PERCENTAGE OF DISPLACER USED.

1C9259–G

A3891–1/IL

Type 2500 Controller or 2500T

Transmitter

Note

In the following steps the output pres-

sure can go as high as the controller

supply pressure.

1. Turn on the supply pressure and check that the

supply pressure gauge reads 20 psig (1.4 bar) for a 3

to 15 psig (0.2 to 1 bar) or 35 psig (2.4 bar) for a 6 to

30 psig (0.4 to 2 bar) output pressure range. If the

pressure is incorrect, loosen the locknut of the Type

67FR filter/regulator (figure 11); turn the adjusting

screw clockwise to increase the pressure or, counter-

clockwise to decrease the pressure. Tighten the lock-

nut after setting the regulator pressure.

2. Set the process variable to its minimum value.

3. Make sure that the PROPORTIONAL BAND or

SPECIFIC GRAVITY control is at the setting deter-

mined earlier in this section. Then, set the RAISE

LEVEL or ZERO ADJUSTMENT control at an ap-

propriate value according to table 4. This table gives

recommended settings based on maximum and mini-

mum possible PROPORTIONAL BAND and SPECIF-

IC GRAVITY settings. If an intermediate PROPOR-

TIONAL BAND or SPECIFIC GRAVITY setting is

necessary, extrapolation may be used to determine an

appropriate RAISE LEVEL or ZERO ADJUSTMENT

setting.

Note

The raise level dial does not reflect actu-

al fluid level in the tank or fluid level

position on the displacer.

4. The OUTPUT gauge on a 3 to 15 psig (0.2 to 1

bar) range should read 3 psig (0.2 bar) for direct or 15

psig (1 bar) for reverse action. On a 6 to 30 psig (0.4

to 2 bar) range the OUTPUT gauge should read 6 psig

(0.4 bar) for direct or 30 psig (2 bar) for reverse action.

5. On a controller or transmitter with a mechanical

indicator assembly, the pointer should be over the

LOW point on the indicator plate. If a slight adjustment

is necessary, loosen the side hex clamp nut (key 40,

figure 19), shift the pointer, and retighten the nut.

6. Increase the process variable to the level desired

for full output change. The OUTPUT gauge on a 3 to

15 psig (0.2 to 1 bar) range should read 15 psig (1

bar) for direct or 3 psig (0.2 bar) for reverse action. On

a 6 to 30 psig (0.4 to 2 bar) range the OUTPUT gauge

should read 30 psig (2 bar) for direct or 6 psig (0.4

bar) for reverse action. On a controller or transmitter

with an indicator assembly, the pointer should be over

the HIGH point on the indicator plate; slight plate ad-

justment may be necessary, as described at the end

of step 5.

7. If all prestartup checks are satisfactory, go to the

startup procedure. If performance is unsatisfactory,

proceed to the Calibration section.

Type 2500S Controller

Note

In the following steps the output pres-

sure can go as high as the controller

supply pressure.

1. Turn on the supply pressure and check that the

SUPPLY pressure gauge reads 20 psig (1.4 bar) for a

0 to 20 psig (0 to 1.4 bar) output pressure range or 35

psig (2.4 bar) for a 0 to 35 psig (0 to 2.4 bar) output

pressure range. If the pressure is incorrect, loosen the

locknut of the Type 67FR filter/regulator (figure 11);

turn the adjusting screw clockwise to increase the

pressure or counterclockwise to decrease pressure.

Tighten the locknut after setting the pressure.

2. Set the process variable to its minimum value.

3. On a controller with a mechanical indicator assem-

bly, the pointer should be over the LOW point on the

indicator plate. If a slight adjustment is necessary,

loosen the hex clamp nut (key 40, figure 19), shift the

pointer and retighten the nut.

Loading...

Loading...