Type 2500

17

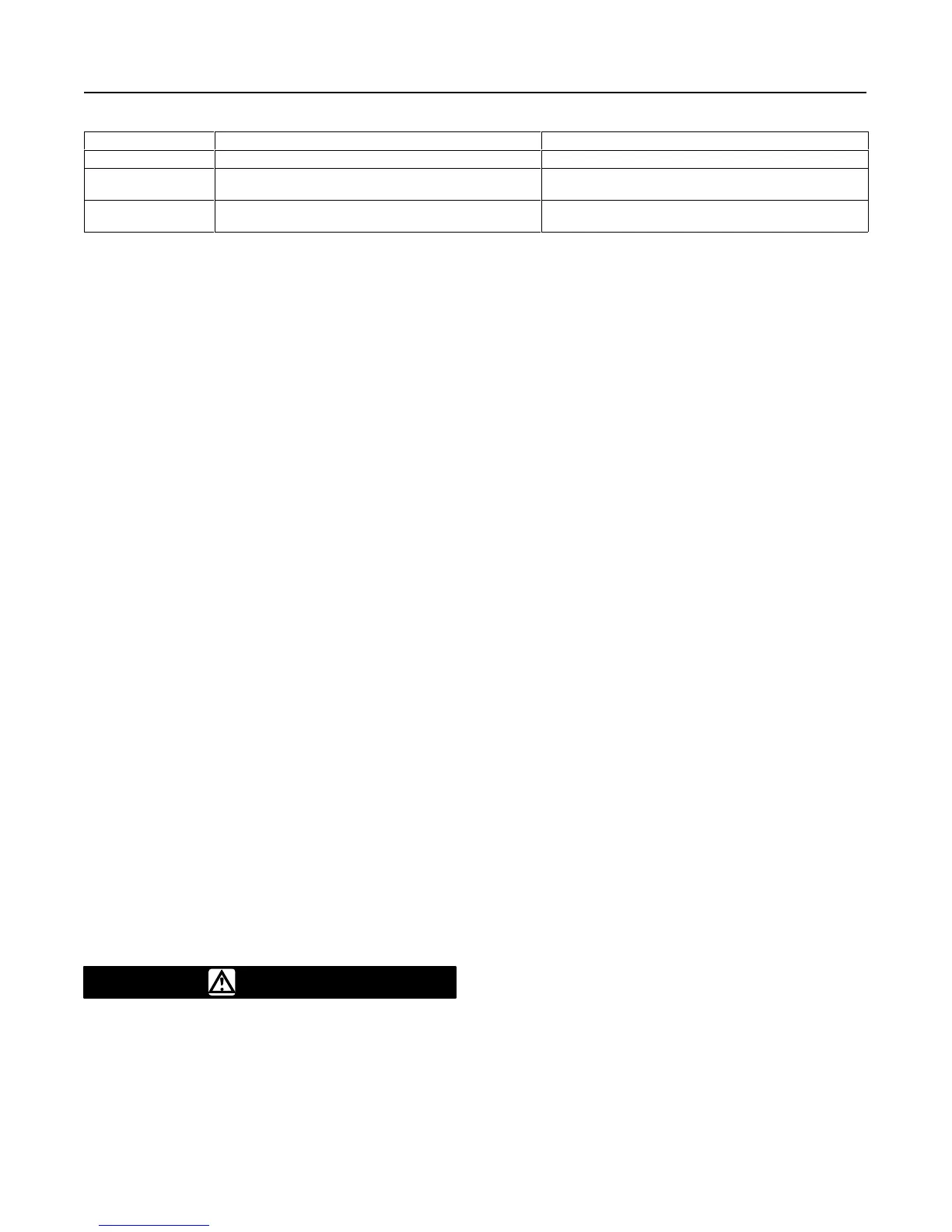

Table 5. Minimum and Maximum Limits for Setting Process Variables

APPLICATION MINIMUM LIMIT MAXIMUM LIMIT

Liquid Level Displacer must be completely out of liquid Displacer must be completely submerged in liquid

Interface Displacer must be completely submerged in lighter of two

process liquids

Displacer must be completely submerged in

heavier of two process liquids

Density Displacer must be completely submerged in liquid having

specific gravity of lowest range point

Displacer must be completely submerged in liquid having

specific gravity of highest range point

0.0361 = Weight of one cubic inch of water

(specific gravity = 1.0), in pounds.

V

= Volume, in cubic inches, of the portion

of the dis

-

placer submerged. Or,

V = (π/4) (displacer diameter)

2

(length of displacer

submerged)

SP

GR = Specific gravity of

the process fluid at operating

temperature.

For interface level measurement, the equation be-

comes:

W

s

+ W

d

–[(0.0361)(V

t

)(SP GR

l

)

) (0.0361)(V

h

)(SP GR

h

* SP GR

l

)]

where:

V

t

= Total volume, in cubic inches, of the displacer.

SP

GR

l

= Specific gravity of the lighter of the fluids at oper

-

ating temperature.

V

h

= Volume, in cubic inches, of the portion of the

displacer submerged in the heavier of the

fluids.

Or,

V

=

(π

/4) (displacer diameter)

2

(length

of the displac

-

er submerged)

SP

GR

h

= Specific gravity of the heavier

of the fluids at op

-

erating temperature.

Calibration Procedure

WARNING

The following calibration procedures

require taking the controller/transmitter

out of service. To avoid personal injury

and property damage caused by an un-

controlled process, provide some tem-

porary means of control for the process

before taking the controller/transmitter

out of service.

Figure 12 shows adjustment locations, except as

otherwise indicated. In order to calibrate, open-loop

conditions must exist. One way to obtain an open loop

is to ensure that there is no flow through the final con-

trol element. Another way to obtain an open loop is to

disconnect the controller/transmitter output signal line

and plug the output connection with a test pressure

gauge.

Several steps in these calibrating procedures require

setting the process variable at its minimum and maxi-

mum limits, according to table 5.

Note

If the process cannot be varied readily

or the Wet Calibration method cannot be

used in the following steps, be sure to

use the proper sequence of correct

weights as found in the Determining

Amount of Suspended Weight proce-

dure. Whenever the following steps re-

quire particular prestartup checks, refer

to the appropriate procedures for: Type

2500 Controller or 2500T Transmitter,

Type 2500S Controller, or Type 2503

Controller.

Type 2500 Controller and 2500T

Transmitter

1. Turn on the supply pressure and check that it is set

according to the appropriate prestartup checks proce-

dure.

2. Make sure that the PROPORTIONAL BAND or

SPECIFIC GRAVITY adjustment is at the setting de-

termined according to the appropriate prestartup

check procedure.

3. Adjust the RAISE LEVEL (Type 2500) or ZERO

ADJUSTMENT (Type 2500T) to the appropriate value

per table 4. This table gives recommended settings

based on maximum and minimum possible PROPOR-

TIONAL BAND (Type 2500) or SPECIFIC GRAVITY

(Type 2500T) settings. If an intermediate PROPOR-

TIONAL BAND or SPECIFIC GRAVITY setting is nec-

essary, extrapolation may be used to determine a new

RAISE LEVEL or SPECIFIC GRAVITY setting.

Loading...

Loading...