Instruction Manual

D200319X012

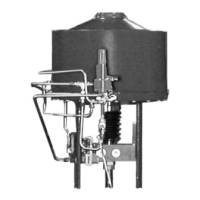

377 Trip Valve

August 2012

12

When supply pressure falls below the trip point, the exhaust port opens venting supply pressure from the lower

diaphragm. This causes the upper ports of the plug assemblies to close and the lower ports to open. Because ports C

and F are plugged, no pressure change occurs on either side of the actuator piston and the piston is pressure‐locked in

position. No volume tank is necessary in this mode.

When supply pressure is restored, the plug assemblies move back into the normal operating position. Supply pressure

from the control device is applied to the actuator through ports A and B and ports D and E.

377U Trip Valve

Figure 9 illustrates trip valve operation in the fail‐up mode. The fail‐up mode of operation is similar to the fail‐down

mode of operation except that the connections to port C and F are reversed. When supply pressure falls below the trip

point, the top of the actuator cylinder vents, and volume tank pressure loads the bottom of the actuator cylinder. The

pressure imbalance created forces the actuator piston up.

Maintenance

Trip valve parts are subject to normal wear so the trip valve must be actuated periodically to determine if it is working

properly. If the trip valve does not work properly, use the following procedures to inspect and repair or replace parts as

necessary. The frequency of inspection and repair or replacement depends upon the severity of service conditions. Be

sure to note the location of all pressure connections to ensure proper trip valve installation upon reassembly, or use

the installation procedures in this instruction manual. All key numbers refer to figure 10 unless otherwise indicated.

WARNING

Avoid personal injury or property damage from sudden release of process pressure or bursting of parts. Before performing

any maintenance operations:

D Always wear protective clothing, gloves, and eyewear when performing any maintenance operations to avoid personal

injury.

D Do not remove the actuator from the valve while the valve is still pressurized.

D Disconnect any operating lines providing air pressure, electric power, or a control signal to the actuator. Be sure the

actuator cannot suddenly open or close the valve.

D Use bypass valves or completely shut off the process to isolate the valve from process pressure. Relieve process pressure

from both sides of the valve. Drain the process media from both sides of the valve.

D Vent the power actuator loading pressure and relieve any actuator spring precompression.

D Use lock‐out procedures to be sure that the above measures stay in effect while you work on the equipment.

D Check with your process or safety engineer for any additional measures that must be taken to protect against process

media.

Periodic Operational Check

WARNING

The following procedure requires taking the trip valve out of service. To avoid personal injury and property damage by

uncontrolled process medium, provide some temporary means of control of the process medium while the trip valve is out

of service.

Loading...

Loading...