Instruction Manual

D103175X012

GX Valve and Actuator

July 2017

18

16. Remove the Belleville spring pack (key 34) and packing spacer (key 30) from the bonnet (key 4). Carefully push out

the remaining packing box parts from the bonnet (key 4) using a rounded rod or other tool which will not scratch

the packing box wall. Clean the packing box and the metal packing box parts.

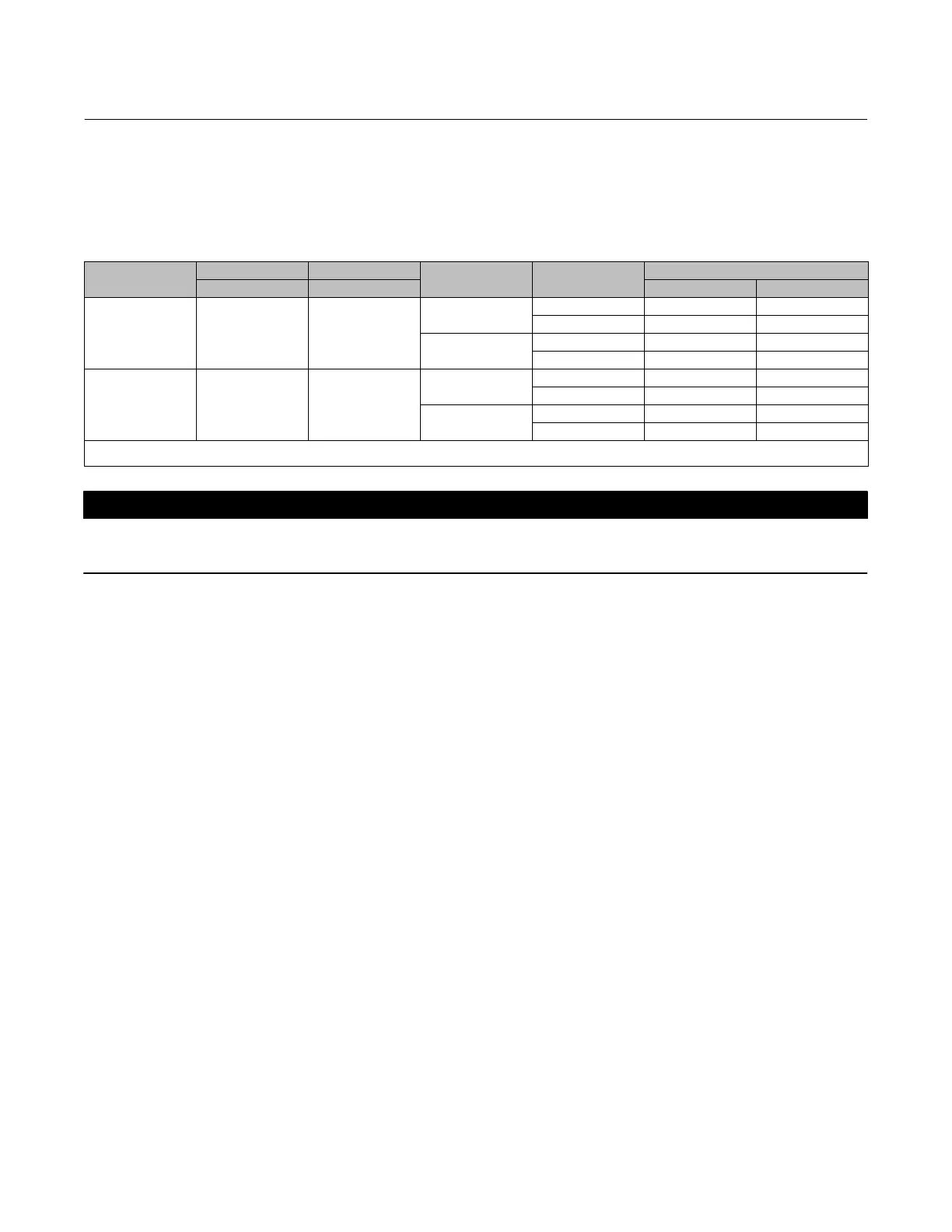

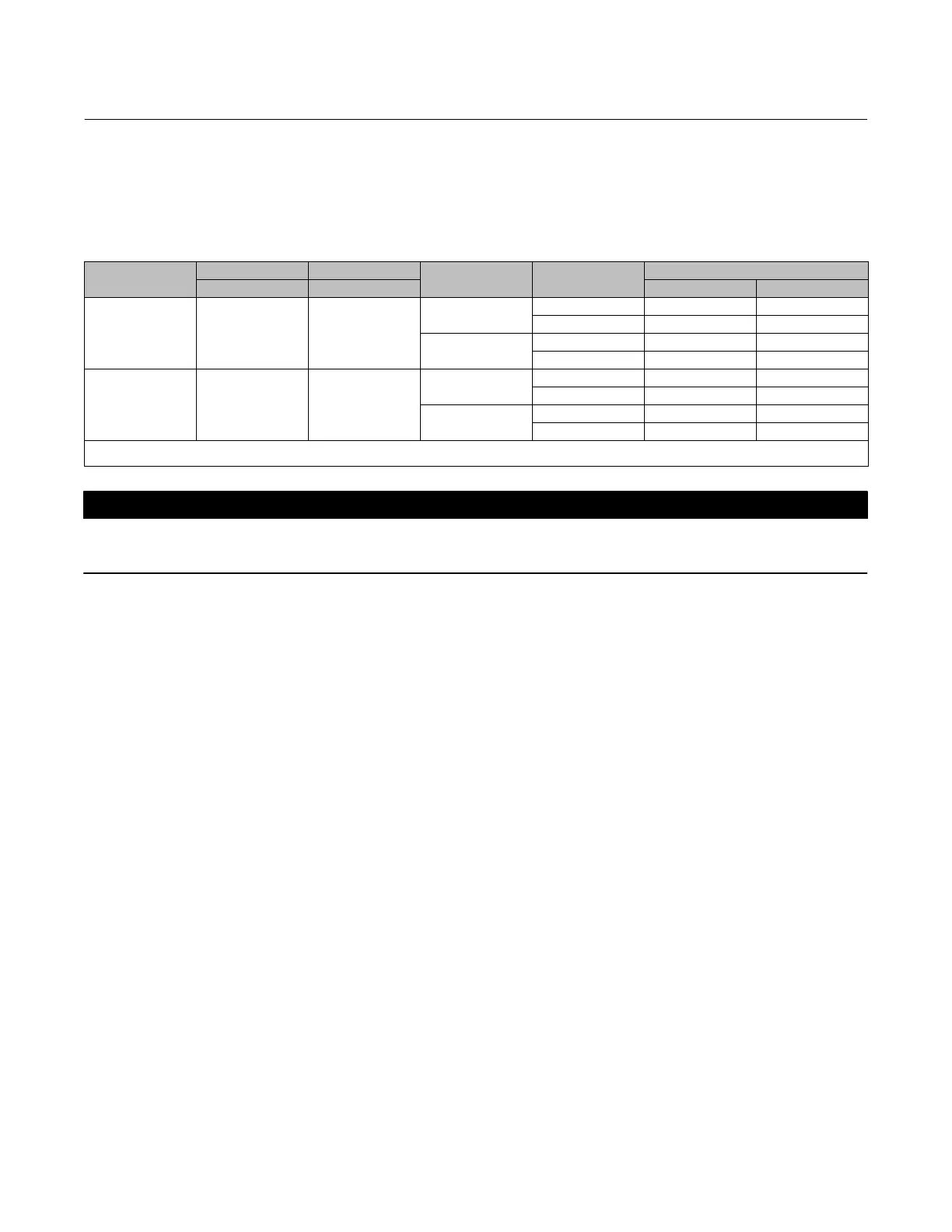

Table 11. GX Electric Actuator Maximum Allowable Thrust

VALVE SIZE

STEM DIAMETER TRAVEL

BONNET STYLE

STEM MATERIAL

STRENGTH

MAXIMUM THRUST

mm mm N lbf

DN25 to DN50

(NPS 1 to 2)

10 20

Plain

High

(1)

17000 3820

Low

(2)

7600 1710

Bellows/Extension

High

(1)

11400 2560

Low

(2)

6700 1500

DN80 to DN100

(NPS 3 to 4)

14 20, 40

Plain

High

(1)

20000 4500

Low

(2)

20000 4500

Bellows/Extension

High

(1)

20000 4500

Low

(2)

14500 3260

1. High strength stem materials consist of S200910, N05500, S31603.

2. Low strength materials consist of S31803, N10675, N06022.

CAUTION

Inspect the valve stem, threads and packing box surfaces for any sharp edges that might cut the packing. Scratches or burrs

could cause packing box leakage or damage the new packing.

17. Inspect the valve stem, threads and packing box surfaces for any sharp edges that might cut the packing.

Scratches or burrs could cause packing box leakage or damage the new packing. If the surface condition cannot be

improved by light sanding, replace the damaged parts.

18. Remove the covering protecting the valve cavity and install a new valve/yoke gasket (figures 18, 19, 20, and 21

key 5, figures 22 and 23 key 47) making sure that the gasket seating surfaces are clean and smooth.

19. Carefully install the bonnet (key 4) onto the valve stem.

20. Install the new packing and the metal packing box parts according to figure 15 for ENVIRO-SEAL PTFE packing and

according to figure 16 for ENVIRO-SEAL graphite ULF packing. Place a smooth‐edged pipe over the valve stem and

gently tap each soft packing part into the packing box. Apply anti‐seize lubricant to the threads and install the

packing follower (key 29).

21. Install the locknut (key 28) and stem adjustor nut (key 27). Ensure they are aligned with the mark made on the

stem disassembly and tighten

For standard bonnet constructions, install the valve plug/bonnet sub assembly into the valve body (key 1).

22. Mount the actuator onto the valve and install the body nuts (figures 18, 19, 20, 21 key 7, figures 22 and 23 key

46), but tighten them only finger‐tight.

23. For standard bonnet constructions, tighten the body nuts (key 7) evenly using a cross‐tightening procedure. See

table 4 for torque requirements.

For extension and bellows bonnet constructions, tighten the bonnet nuts (key 46) evenly using a cross‐tightening

procedure. See table 5 for torque requirements.

24. Push the valve plug/stem to the valve seat. Thread the stem adjustor nut (key 27) and locknut (key 28) to the

previously marked position. Thread the locknut (key 28) up against the stem locknut and tighten to the torque

specified in table 6.

25. Stroke the actuator rod until it contacts the stem adjuster nut (key 27) and install the stem connector halves and

travel indicator (keys 23, 24, and 26) with the cap screws (key 25). Install the stem connector halves in the proper

orientation so that when looking at the inside of the stem connector halves, the flats are down and the beveled

surfaces are up.

Loading...

Loading...