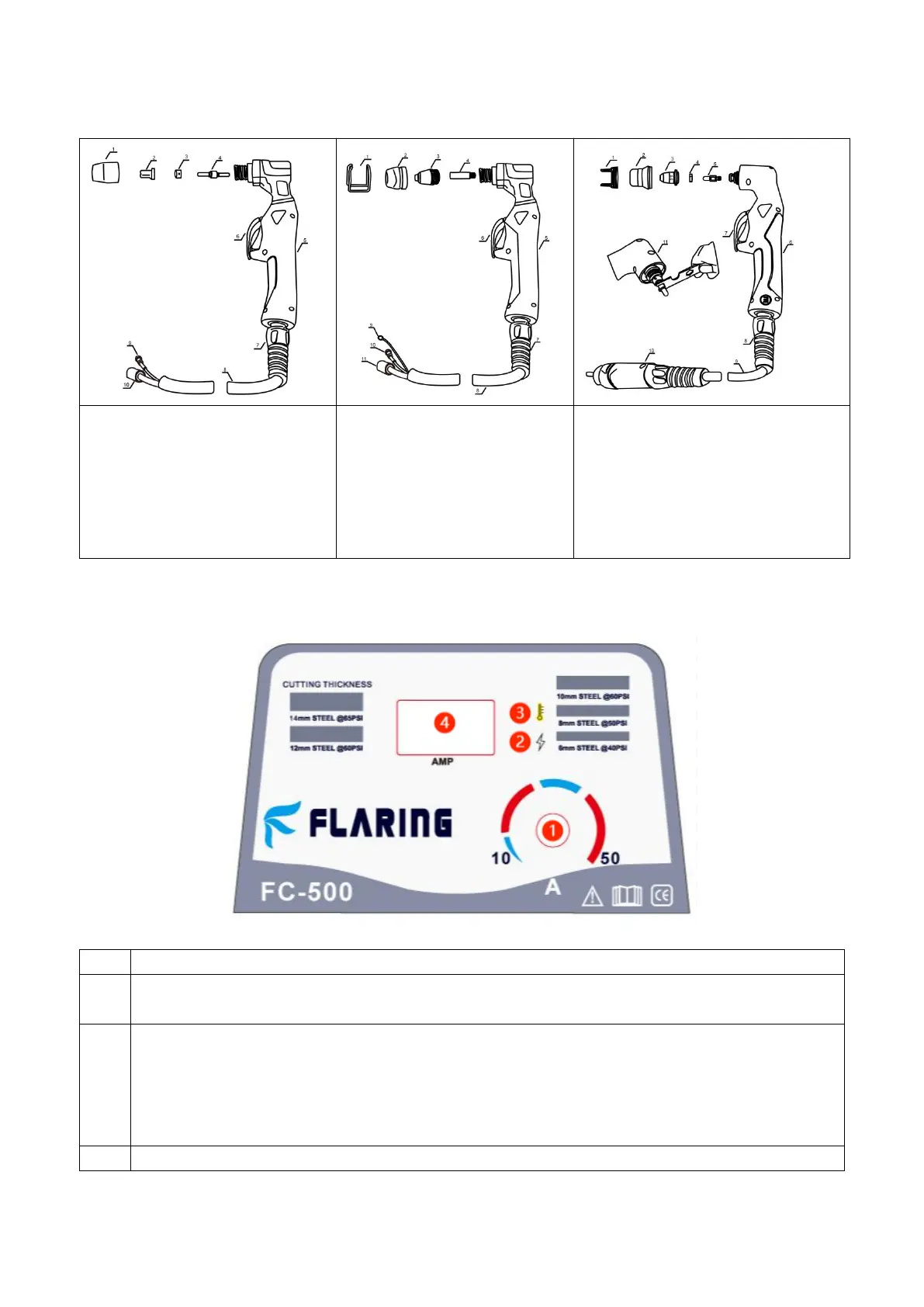

2.4 Cutting Torch

explosive chart

A=PT31 Torch

1.Outside nozzle, 2.Extend tip,

3.Diffuser, 4.Electrode. These are

wear parts, among which the extend

tip and electrode are very easy to

wear, please keep it.

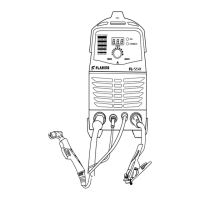

B=AG60 Torch

1.Spacer spring, 2.Outside nozzle,

3.Extend tip, 4.Electrode. These are

wear parts, among which the

extend tip and electrode are very

easy to wear, please keep it.

C=IPT60 Torch

1.Double pointed spacer, 2.Outside

nozzle, 3.Extend tip, 4.Diffuser,

5.Electrode. These are wear parts, among

which the extend tip and electrode are

very easy to wear, please keep it.

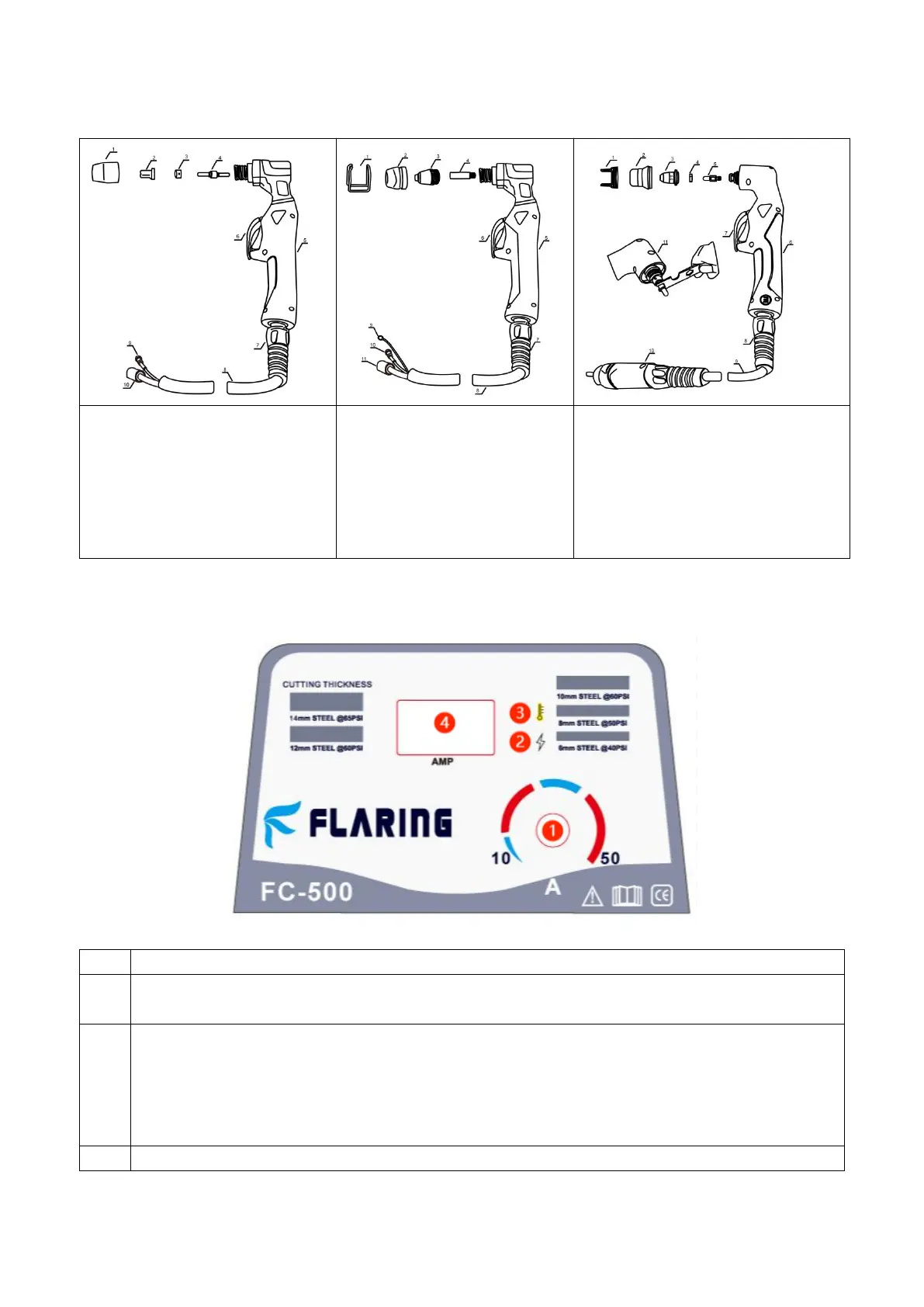

3 Operating instructions

3.1 Operation panel interface

1

Current adjust knob

2

Power light

When this light is on, it means that the power supply is normal.

3

Over current or over heat protection light

When the cutting load is overloaded and the output current of the machine is too large, the internal temperature of

the machine is too high, and the machine fault light will be on. This is normal. The machine can recover after the

heat dissipation becomes normal. Please restart the power supply; When damaged, the fault light will be on, in

this case, the machine is abnormal and needs maintenance, please contact the supplier.

4 Current display meter,Display preset current and actual current during operation

Loading...

Loading...