3.3 Start Cutting

3.3.1 Edge cutting

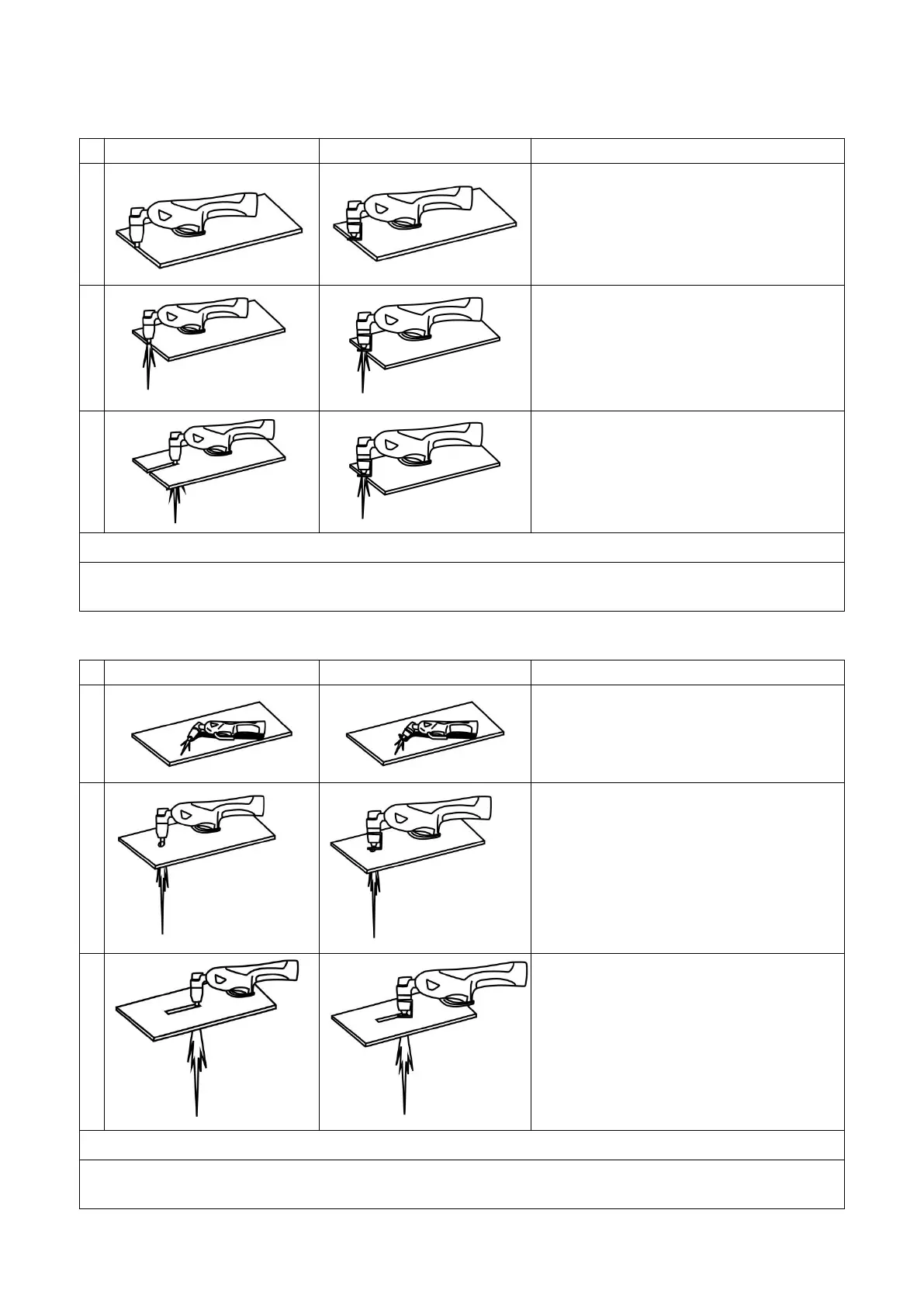

Touch No Touch Remarks

1 Keep the torch vertical at the edge of the

workpiece. Keep your wrist steady and ready to

start cutting

2 Pull the trigger to start the arc ,The cutting arc

will initiate when the torch tip is close enough to

the work Piece. Start cutting on the edge until

the Arc has cut completely through.

3 During the cutting process, it is necessary to

control the speed. Too fast speed will lead to

incomplete cutting, and arc blowback is easy to

damage the device. Too slow speed will lead to

excessive scum and cutting gap.

Touch:A=High Frequency Plasma Cutter/PT31

No Touch:B=No Touch Pilot Arc High Frequency Plasma Cutter/AG60

C=

Non Touch Pilot Arc Low Frequency Plasma Cutter/IPT60

3.3.2 Piercing Cutting

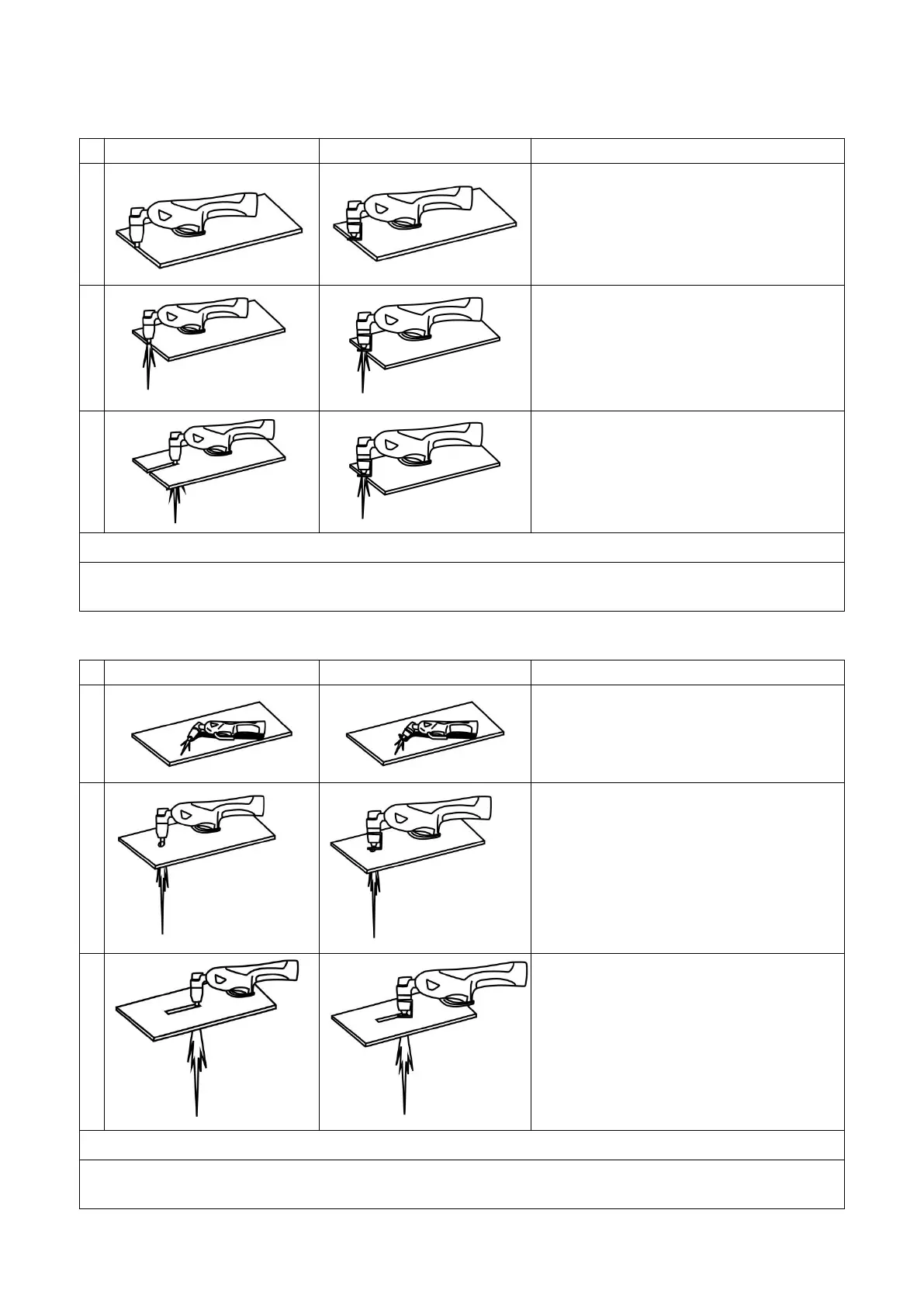

Touch No Touch Remarks

1 Hold the torch at an angle to the work piece, pull

the trigger to start the arc and slowly rotate it to

an upright position.

2 Pull the trigger to start the arc ,The cutting arc

will initiate when the torch tip is close enough to

the work Piece. Start cutting on the edge until

the Arc has cut completely through.

3 When the pierce is complete, Control the cutting

speed and adjust the angle and position of the

cutting torch to continue the cutting

operation.Too fast speed will lead to incomplete

cutting, and arc blowback is easy to damage the

device. Too slow speed will lead to excessive

scum and cutting gap.

Touch:A=High Frequency Plasma Cutter

No Touch:B=No Touch Pilot Arc High Frequency Plasma Cutter,C=

Non Touch Pilot Arc Low Frequency Plasma

Cutter

Loading...

Loading...