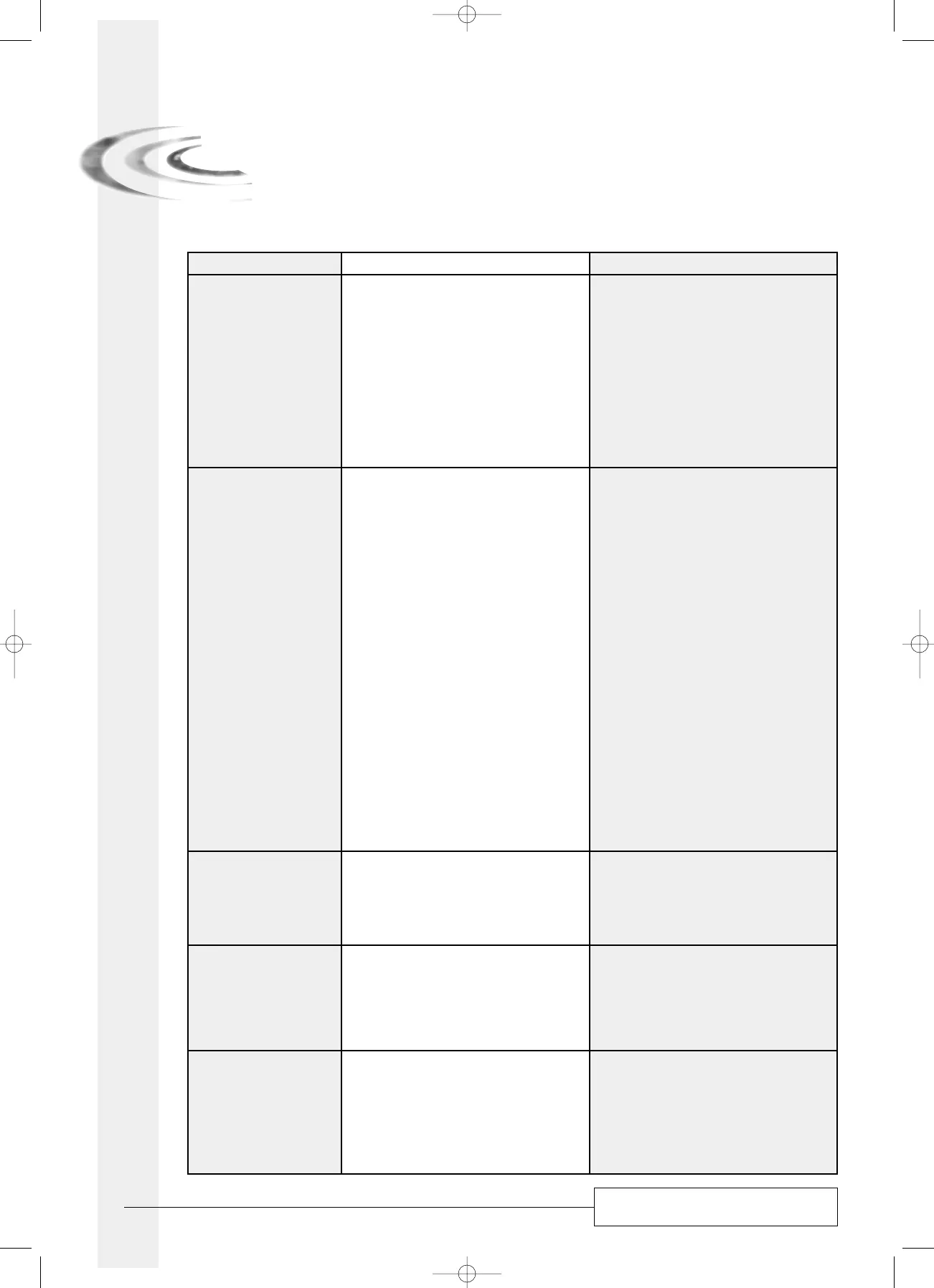

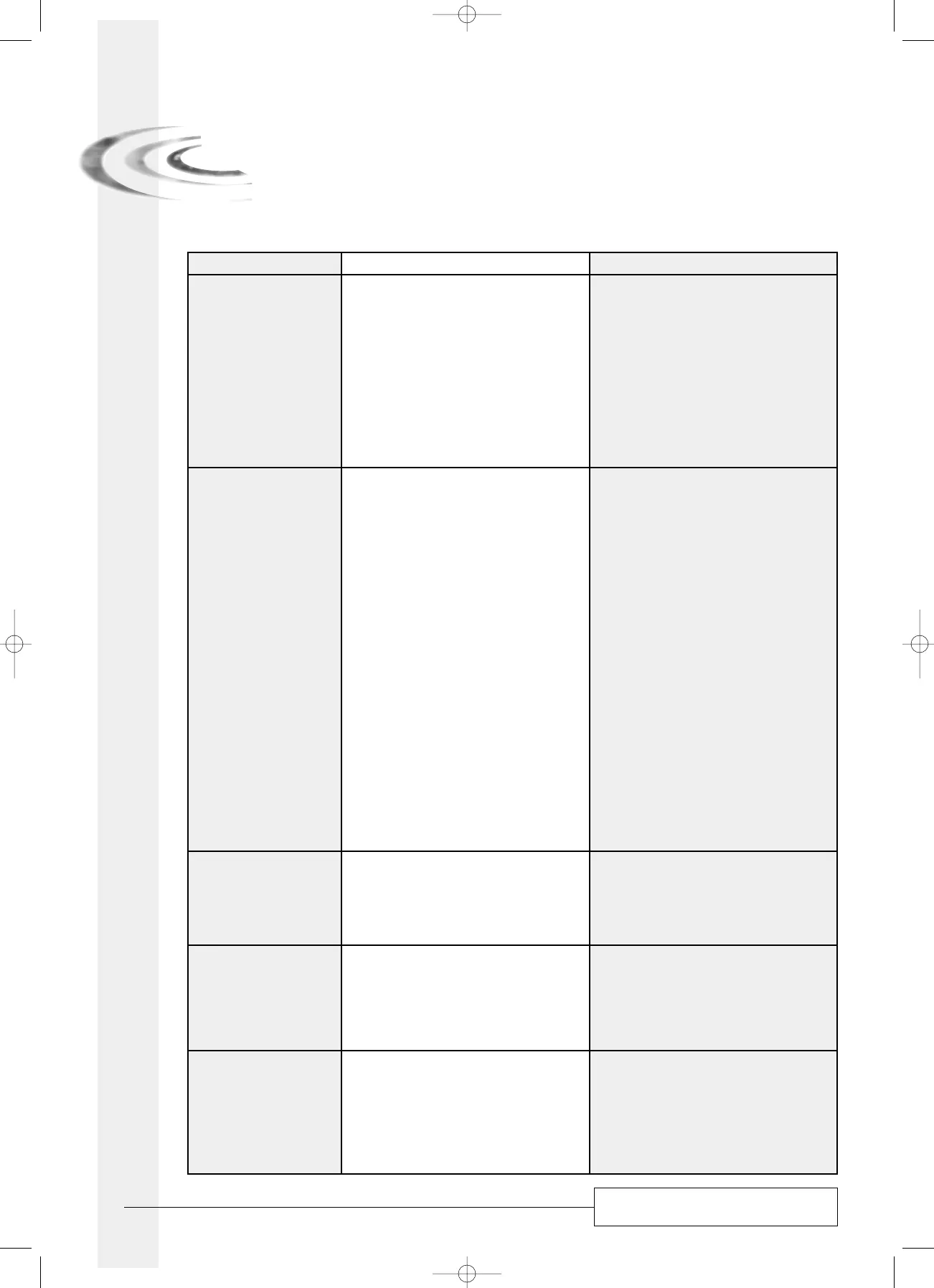

5 - TROUBLESHOOTING

7

7700 VALVE

PROBLEM CAUSE CORRECTION

1. Softener fails A. Electrical service to unit has been interrupted. A. Assure permanent electrical service

to regenerate (check fuse, pull chain or switch).

B. Timer is not operating properly B. Replace the timer.

C. Meter cable disconnected. C. Check the meter connection to the

timer and the meter cover.

D. Jammed meter. D.Clean or replace the meter.

E. Defective valve drive motor. E. Replace the drive motor.

F. Improper programming. F. Check the programming

and reset as needed.

2. Softener delivers A. By-pass is opened. A. Close the by-pass valve.

hard water

B. No salt in the brine tank. B. Add salt to the brine tank and

maintain the salt level above

the water level.

C. Injector or screen is blocked C. Replace or clean the injector

and screen.

D. Insufficient water into the brine tank D. Check the brine tank fill time and clean

the brine flow control if it’s blocked.

E. Hardness from the hot water tank. E. Repeated flushing of the hot water

tank is required.

F. Leak at the distributor tube. F. Make sure the distributor tube is not cracked.

Check the O’ ring and tube pilot.

G. Internal valve leak. G. Replace seals and spacers

and/or piston.

H. Flow meter jammed. H. Remove the obstruction from meter.

I. Flow meter disconnected. I. Check the meter connection

to the timer and the meter cap.

J. Improper programming. J. Check the programming

and reset as needed.

3. Unit uses too much salt A.Improper brine refill setting A. Check salt usage and salt setting.

B. Excessive water in the brine tank. B. See problem n°7.

C. Improper programming. C. Check the programming

and reset as needed.

4. Loss of water pressure A. Iron build up in line to softener. A. Clean the line to the softener.

B. Iron build up in the softener. B. Clean the valve and resin bed.

C. Inlet of the valve plugged due C. Remove the piston and clean

to foreign material. the valve.

5. Loss of resin through A. Top distributor missing or broken. A. Add or replace the top distributor.

drain line

B. Air in water system. B. Ensure the presence of air check

system in the brine tank.

C. Drain line flow control C. Ensure the drain line flow control

is the wrong size. is sized correctly.

Loading...

Loading...