How to fix a Fleck Control Unit when the softener fails to regenerate?

- AAnna MannAug 17, 2025

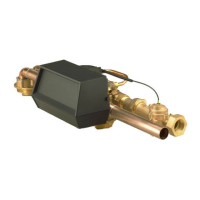

If your Fleck Control Unit softener isn't regenerating, it could be due to several reasons. First, check for any interrupted power supply by restoring electrics (mains, fuse). A defective power head might be the cause, requiring a replacement. Inspect the meter cable connections on the time rand and meter cover. A blocked meter may also prevent regeneration; clean or replace it. If the motor is defective, consider changing it. Lastly, ensure the programming is correct and modify it if necessary.