Page 10 of 18

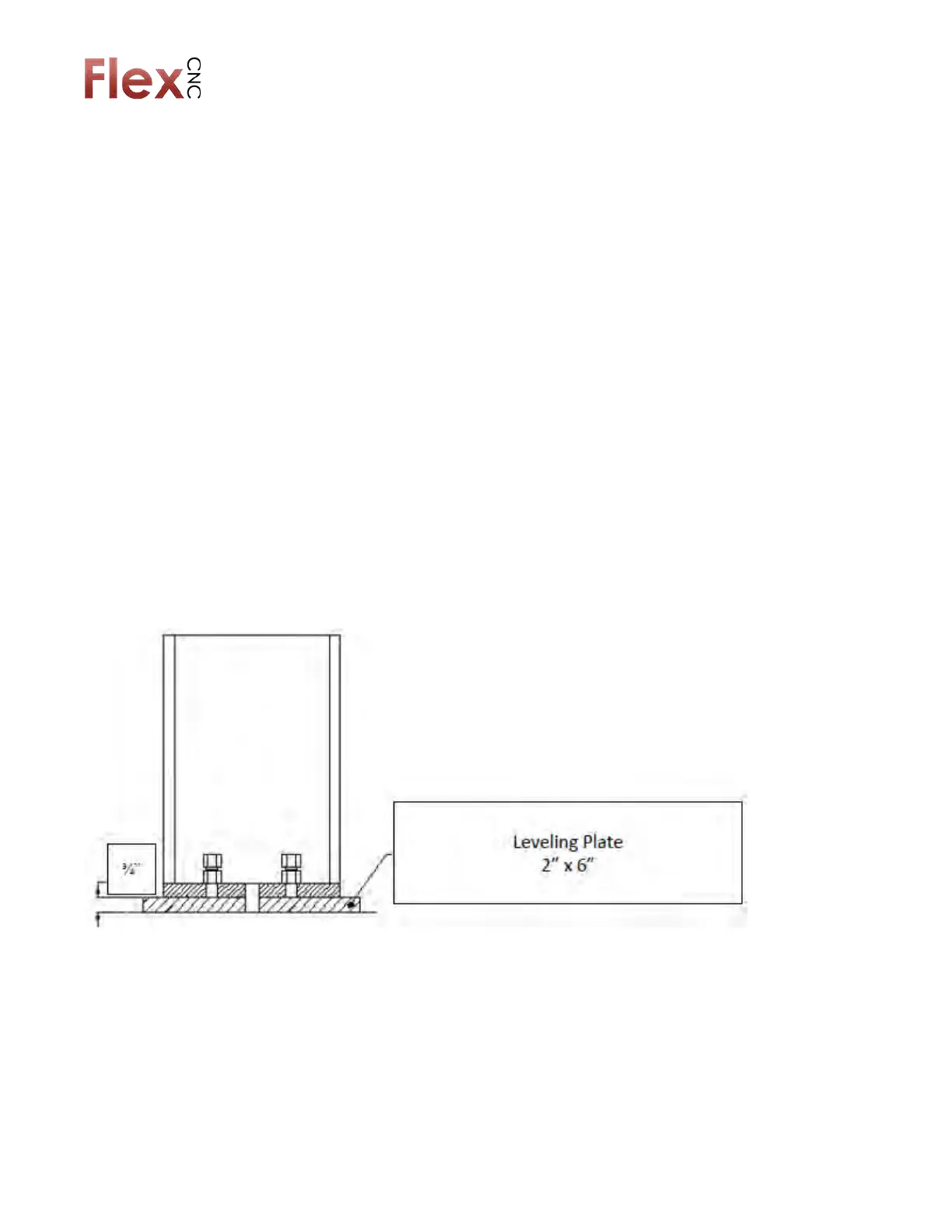

Foundation and Anchoring:

• Steel plate dimensions 2 in. X 6 in. X .75 in.

• Move the machine to appropriate location and lower the machine to the floor.

• Mark the location where lag will need to be placed.

• Drill hole insert lag and epoxy (if using epoxy) then place leveling plates over

anchors.

• Use 5/8” diameter lags by 8” long to secure the machine to the foundation

(not provided by FlexCNC).

• Move machine back into position and carefully lower machine until

approximately one inch above floor.

• Square the plates under every contact foot and then lower the machine

completely until it rests on the floor.

• Use leveling bolts located on every contact foot to level the machine. Use a

leveling tool 8-12” long with a tolerance of .001.

• Once the machine is level, tighten the hex nuts to secure leveled position.

• Re-check in one month to ensure the machine is still level. If the machine is

not level, use the bolts to adjust the machine to a level position.

Loading...

Loading...