INSTALLATION, OPERATION, &

MAINTENANCE MANUAL

TITLE: F7000 / 8000 Series Rev. T

Pilot-Operated Safety Relief Valve Page 28 of 43

5.0 PILOT VALVE SET PRESSURE ADJUSTMENT

5.1

Set pressure is the inlet supply pressure at which main valve dome pressure is reduced so as to permit

the main valve piston to open (based on piston area differential between top and bottom). The ASME Sec.

VIII tolerance on set pressure is + 2 psi for set pressures < 70 psig, and + 3% of set pressure for set

pressures > 70 psig. Contact Flow Safe for confirmation of spring range or new spring part number before

resetting any pilot to a different set pressure.

5.2

PRESSURE ADJUSTMENT / VERIFICATION

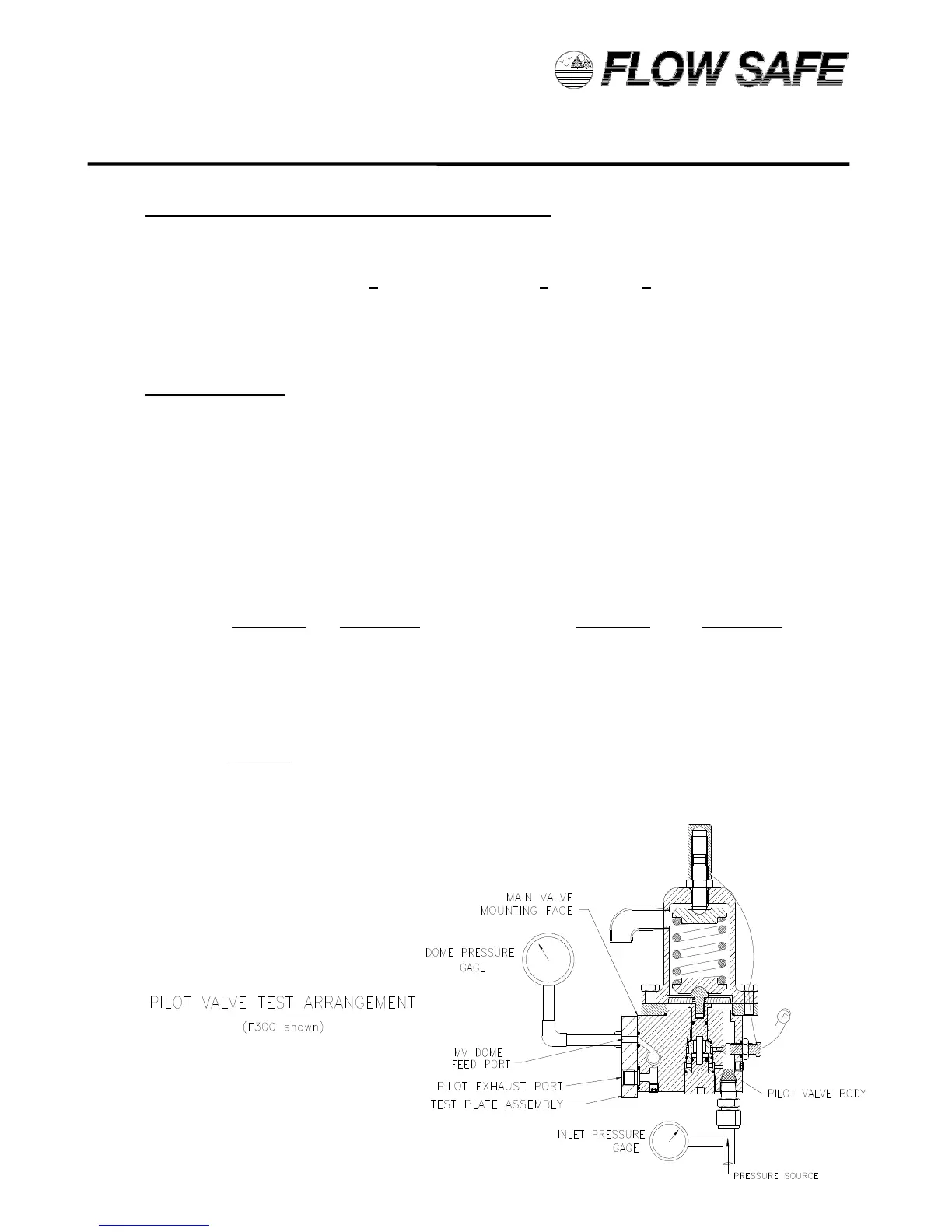

5.2.1 Testing of Pilot Only

Set pressure adjustments can be made with the pilot valve removed from the main valve and connected to

a test plate assembly (available from Flow Safe), as shown below. The adjustment is made by turning the

pressure adjusting screw clockwise (in) to increase set pressure and counterclockwise (out) to decrease

set pressure.

The F200 snap-acting pilot will suddenly exhaust dome to zero in a “pop” action.

F100, F300, and F500 modulating pilots gradually reduce dome pressure to the point where the piston can

lift, as follows:

F7000/8000 Dome Pressure % F7000/8000 Dome Pressure %

Valve Size at Set Point * Valve Size at Set Point *

1 x 2 50 % 6 x 8 80 %

1-1/2 x 3 63 8 x 10 84

2 x 3 68 10 x 12 78

3 x 4 76 12 x 16 73

4 x 6 76 *

Dome pressure as a percentage of inlet pressure,

to achieve main valve piston lift (F100, F300, F500)

Example: For a 3x4 set at 150 psig to begin discharging through the outlet, a modulating pilot

must vent off dome pressure until it drops to approx. 114 psig (0.76 x 150).

Detailed pilot testing instructions are contained in Sections 5.3 through 5.6. Auxiliary setter adjustments

are detailed in 5.7.

Loading...

Loading...