INSTALLATION, OPERATION, &

MAINTENANCE MANUAL

TITLE: F7000 / 8000 Series Rev. T

Pilot-Operated Safety Relief Valve Page 39 of 43

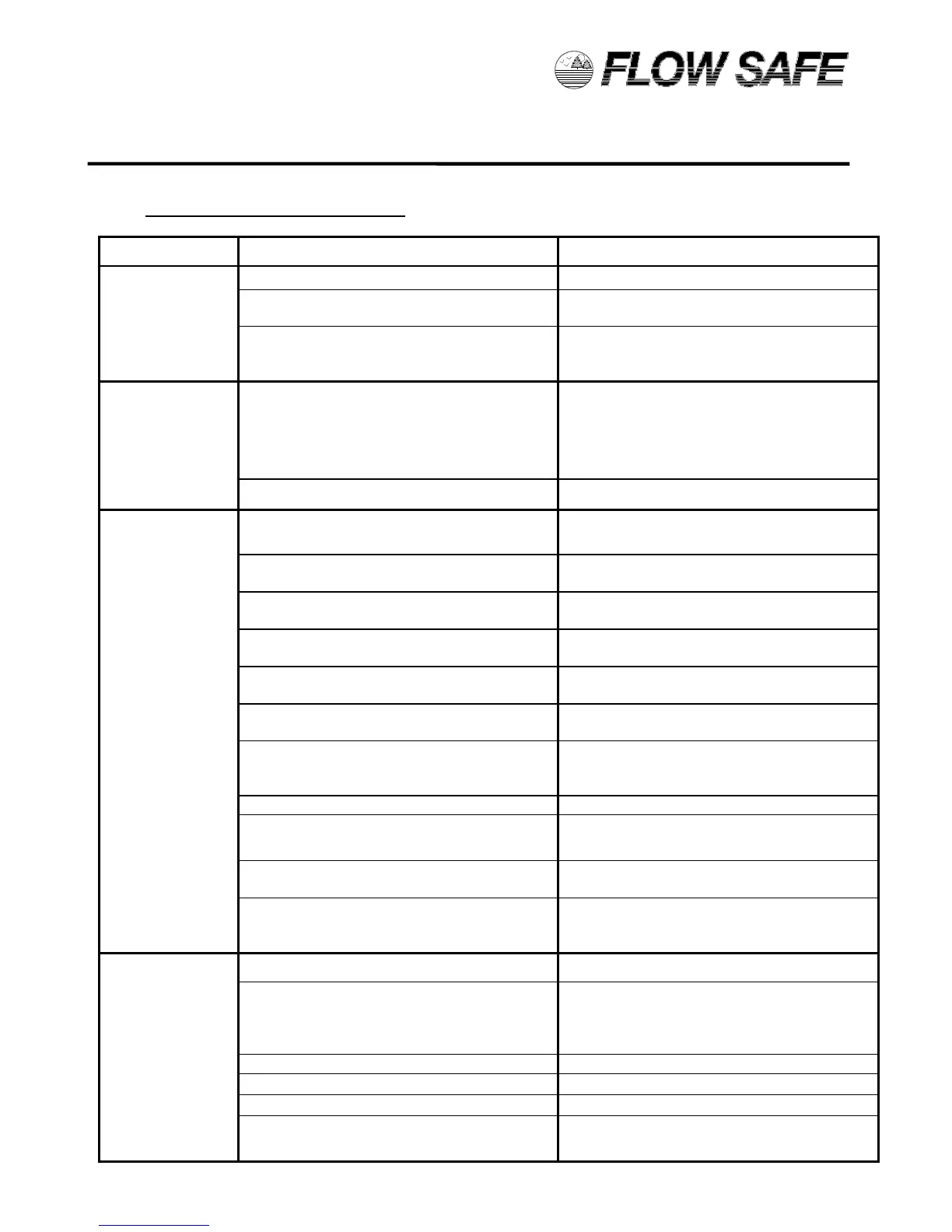

7.0 TROUBLESHOOTING GUIDE:

The main valve

leaks around the

cap.

Inadequate or uneven bolt torque. Retighten the cap bolts per Section 3.2.

Sealing surface on cap is damaged. Repair defect or replace cap.

Upper liner seal is damaged, contaminated,

or not properaly seated.

If damaged, replace with new seal(s). If

contaminated, clean and reinstall with light,

even pressure in groove.

The main valve

leaks through the

outlet.

Damage to, or contamination on: piston

seat or main valve nozzle, piston seal /

sealing surface, or lower liner seal / sealing

surface.

Disassemble the valve, remove the piston

and liner, and examine the seat, seals, and

sealing surfaces under magnification. If

damaged, replace with new part(s); if

contaminated, clean and reinstall.

Dome is not loading properly through pilot. See “The main valve does not close.”

The main valve

does not close.

Obstruction in pilot valve or tubing / filter

from main valve inlet.

Clean / unplug.

Field test connection or tube fitting is

leaking.

Tighten FTC jam nut; replace seal. Tighten

all fittings.

On F200 pilot, bushing is too far into body. Back out bushing and check for proper

blowdown.

F300 proportional band screw is inserted

too far, restricting dome pressurization.

Back out (CCW) band screw until dome

pressure is able to load through pilot.

Pilot diaphragm is leaking. Disassemble pilot valve, remove and inspect

diaphragm. Replace diaphragm.

The pickup tube is oriented incorrectly. Reorient the pickup tube with the port facing

upstream (down).

The pickup tube is damaged or plugged. Inspect the pickup tube for damage.

Replace if necessary. If plugged, clean and

reinstall.

Manual blowdown valve left open. Close manual blowdown valve.

Excessive system debris, interfering with

pilot or main valve seats / seals.

Clean system or provide filtration.

Piston or liner seal is leaking. Disassemble valve, remove the seals and

examine. Clean or replace, as necessary.

Outlet piping is obstructed or too small. Check outlet piping for obstructions. Pipe

size should be at least the nominal size of

the valve outlet.

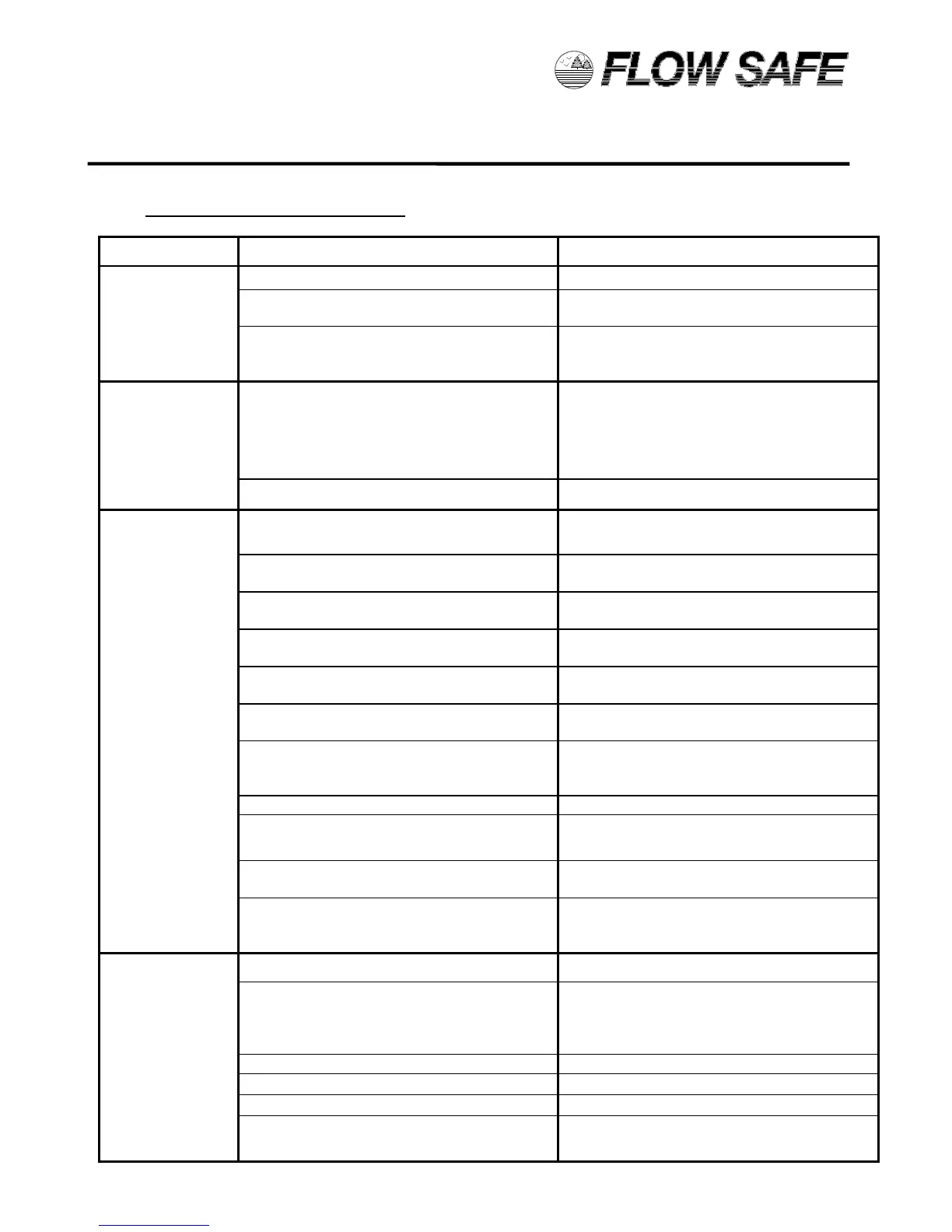

The main valve

does not open.

Pilot valve inlet tubing is plugged. Clean / unplug line.

Contamination between piston and liner. Disassemble valve and examine surfaces.

Clean or replace parts as necessary.

Determine origin of contamination within

system, and clean or provide filtration.

Inlet line blocked. Clear blockage in a safe manner.

Outlet line blocked. Clear blockage in a safe manner.

Pilot valve is plugged. Disassemble and clean pilot assembly.

Increased set pressure due to

auxiliary setter.

Add auxiliary setter differential to

set pressure.

Loading...

Loading...