9

6

MAINTENANCE

6.1 Schedule

The sleeve is the only part of the valve which is in contact with the medium flowing in

the pipeline. With regular sleeve changing, the likelihood of malfunctions in the process

decreases. Wear resistance of the sleeve depends on the circumstances of the process

and may vary a lot.

If there is a flow through closed valve or leakage through bushings (PVE) or through

damaged sleeve (PV), change the sleeve immediately.

WARNING

PVE: In case of a sleeve failure, slight leakage can occur

through bushings.

PV: In case of a sleeve breakage, the flowing liquid will

leak into the environment.

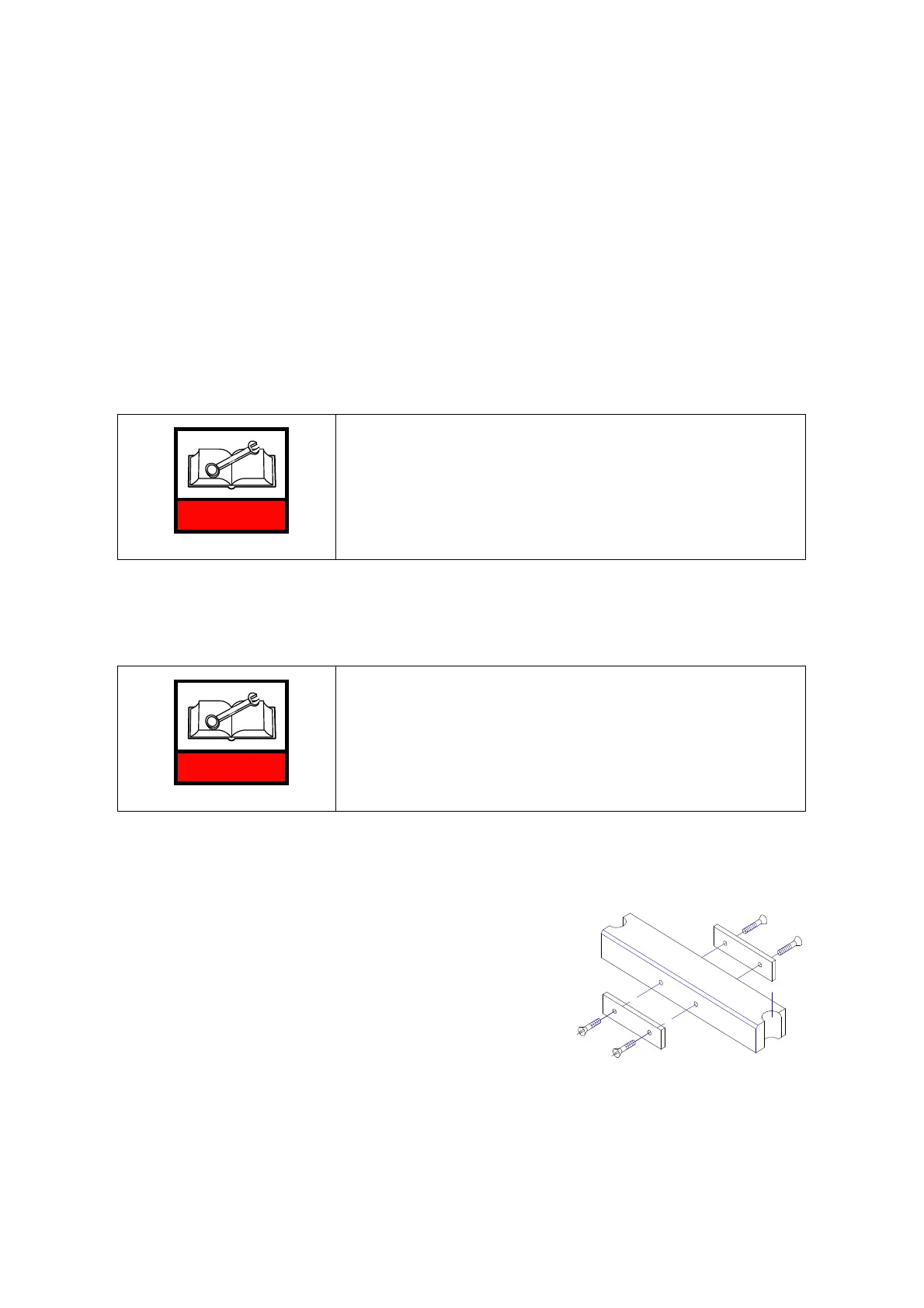

6.2 Changing the valve sleeve

WARNING

Control the valve functions (see 2.3) and follow the

instructions for adjusting of valve (6.3) to prevent

accidents and to ensure the correct operation of the

valve.

6.2.1

Changing the valve sleeve in open model valve (PV)

Fig. 8.

See appendix A. Open the valve and detach it from

the pipeline. If the valve is equipped with opening

tags, loosen the fixing screws (8 pcs) at the pinch

bars and pull out the opening tags (Fig. 8).

Remove the broken sleeve by bending the rubber

flange of the sleeve and by wrenching it e.g. with a

pry bar / bending iron.

Loading...

Loading...