13

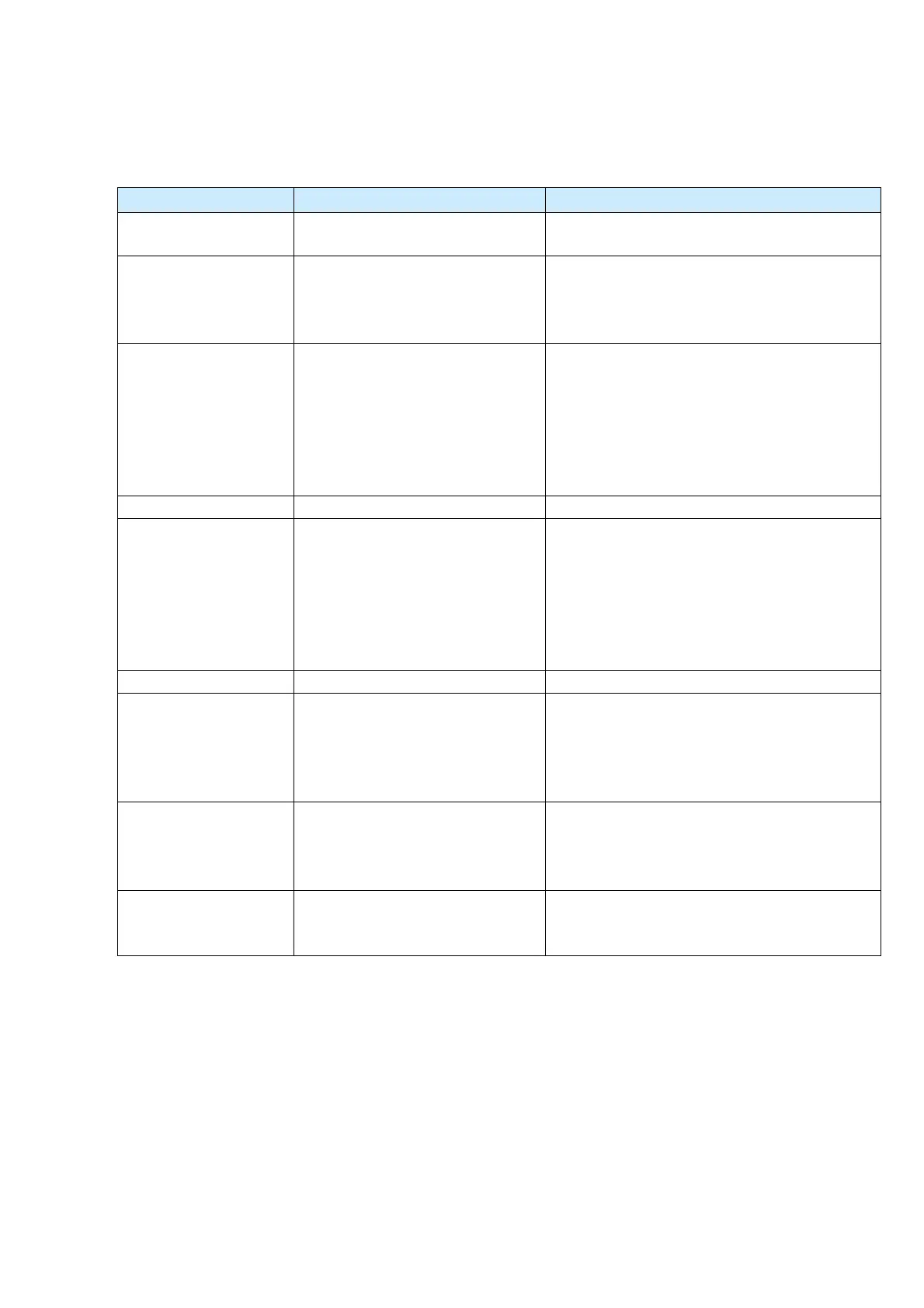

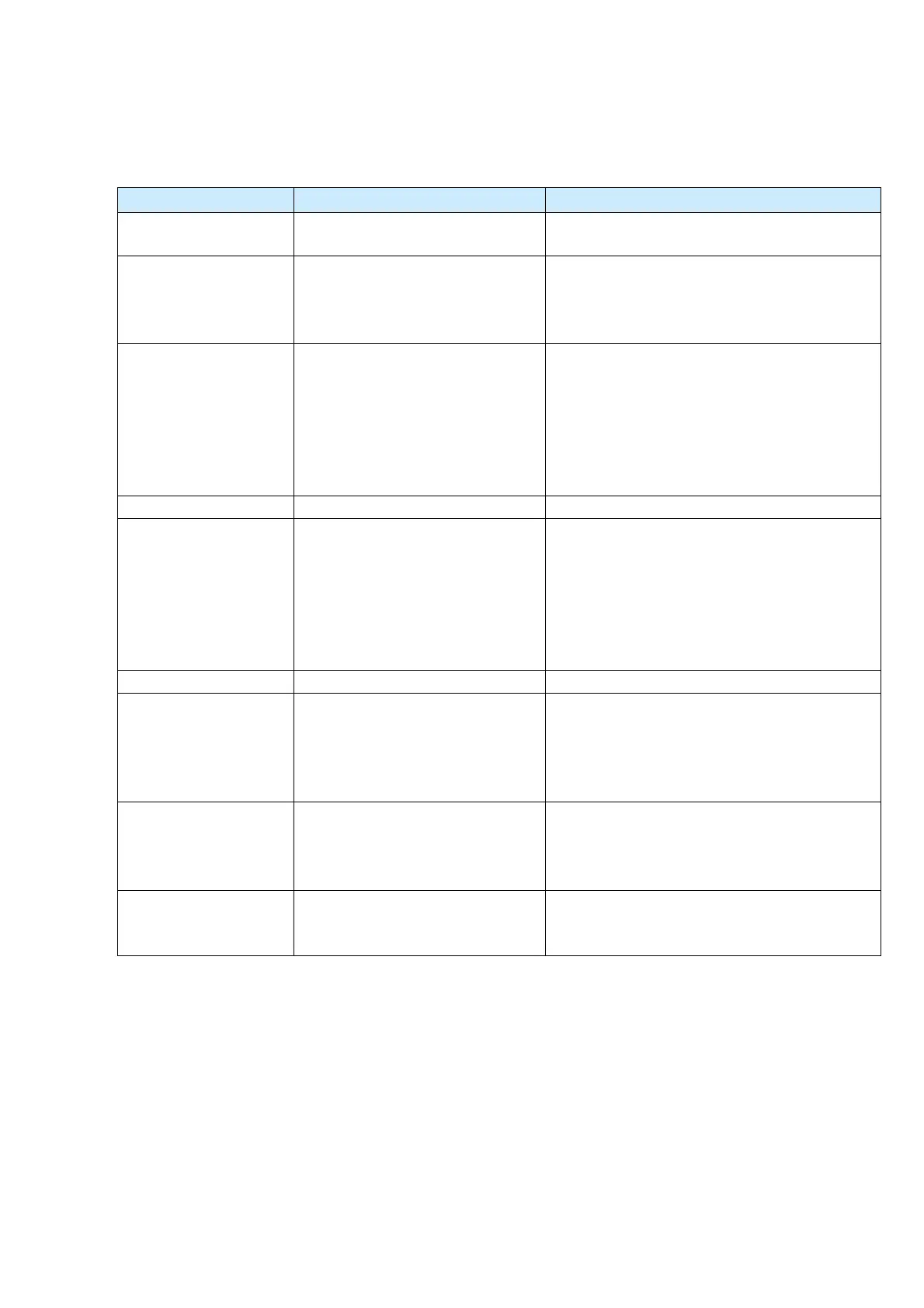

6.4 Troubleshooting

PROBLEM POSSIBLE REASON

ACTION

Valve leaks into the

environment.

1. Sleeve breakage.

2. End flanges loosely tightened.

1. Change and make adjustment of sleeve

2. Tighten the flange end screws

Leakage or flow

through the valve

when valve should be

closed.

Sleeve breakage.

(models PVE, PVS): check by the plug -

change and make adjustment of sleeve

Sleeve is not closed with

sufficient squeeze.

Manual valves - turn the hand wheel more

tight.

Pneum. and hydr. actuators - check the

supply pressure for cylinder; if the pressure

is too low, the sufficient squeeze for the

sleeve cannot be reached. Check the

compactness of the cylinder seals.

Wrong adjustment of the sleeve.

Make the adjustment

Shorter lifetime of the

sleeve than before.

Sleeve is not closed with

sufficient squeeze.

Manual valves - turn the hand wheel more

tight.

Pneum. and hydr. actuators - check the

supply pressure for cylinder; if the pressure

is too low, the sufficient squeeze for the

sleeve cannot be reached. Check the

compactness of the cylinder sealings.

Wrong adjustment of the sleeve.

Make the adjustment.

1. Pneum. valves: wrong

adjustment of the end cushioning

in front end-block of cylinder.

2. Wrong adjustment of the

pneum. spring.

1. End cushioning in front end-block of

cylinder should be fully open.

2. Check adjustment of pneumatic spring .

Changes in customer process e.g.

∗

composition of medium /

temperature

∗

flow capacity

Check the best rubber qualityl

with

FLOWROX.

Select another valve size with FLOWROX

(particularly valves with positioners).

Sleeve is flapping

and/or flow capacity

is not sufficient.

Vacuum or pressure shocks in

pipeline, rubber has hardened

and does not open totally.

Chec

that the opening tags are fixed.

In case you cannot find the solution to your problem in the above table, please turn to

the nearest Flowrox representative. The serial number and type identification of the

valve in question will help getting the prompt answer.

Loading...

Loading...