FRBH, FRBHX AND FRBHS USER INSTRUCTIONS ENGLISH 71569178 20-08

Page 51 of 60 Flowserve.com

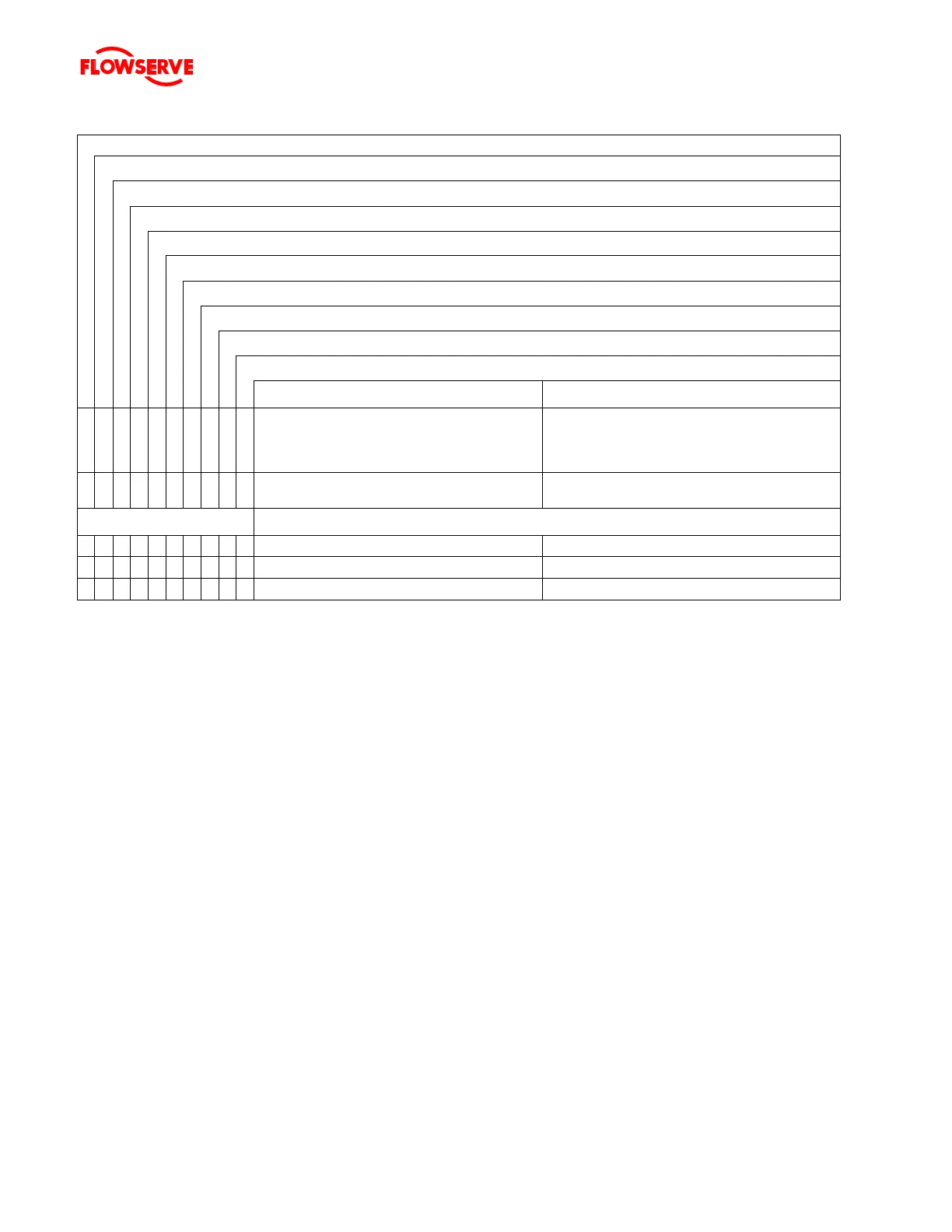

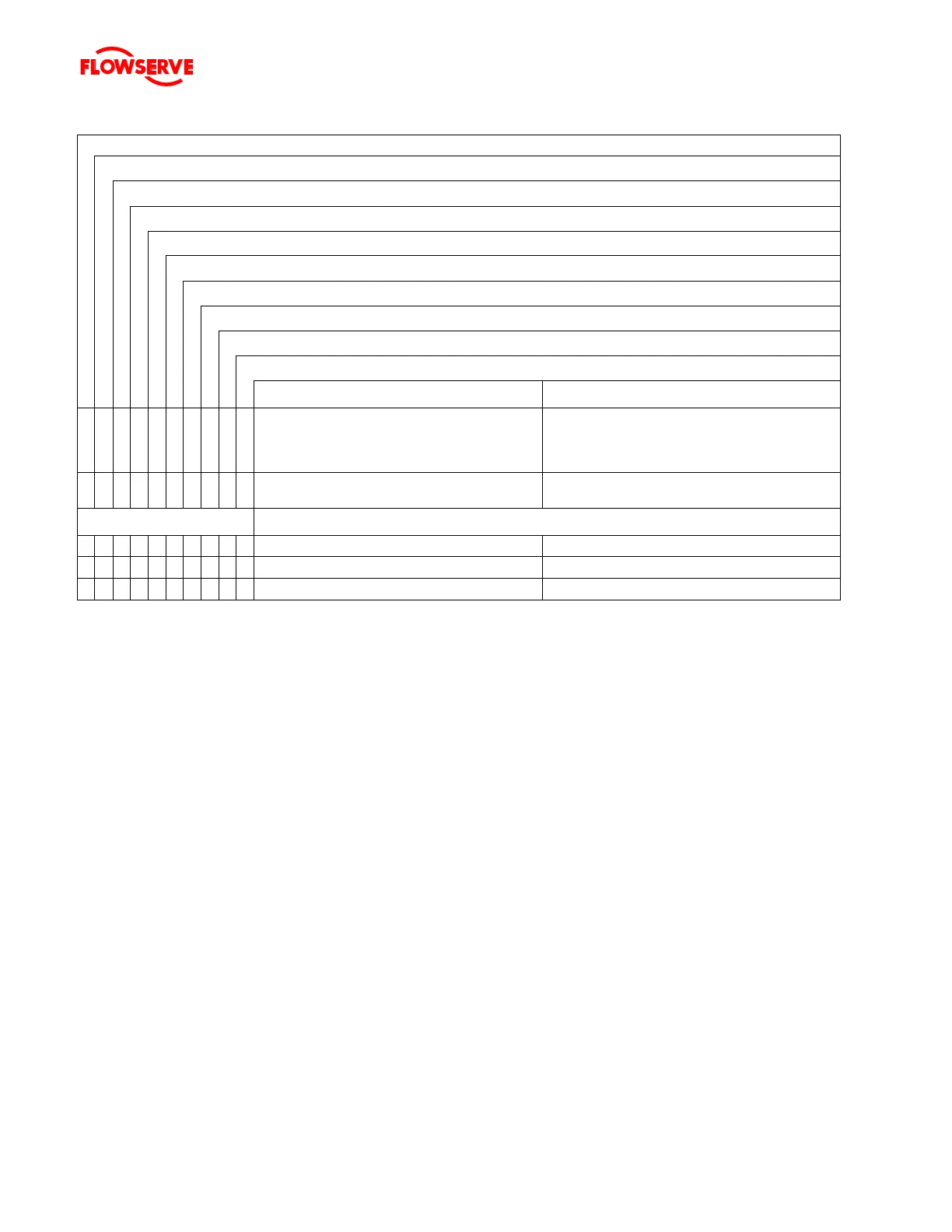

Pu mp o v er h e at s an d s eiz e s

B e ar i n g s h a v e s hor t l i f e

Pu mp v ib r a t e s o r i s n o i s y

M e c h a n i c a l s e al h a s s h o r t l i f e

M e c h a n i c a l s e al l e a k s e x c e s s i v e l y

Pu mp r e q u i r e s e x c es s i v e p o w e r

Pu mp l o s e s p r i m e af t e r s t a r t i n g

In suf f i c i e n t p r es s u r e d ev e l o p e d

In suf f i c i e n t c a p a ci t y d e l i v er e d

Pu mp d o e s n ot d el iv e r li q u i d

Improper installation of bearings (damage during

assembly, incorrect assembly, wrong type of

bearing etc).

Check method of assembly, possible damage or

state of cleanliness during assembly and type of

bearing used. Remedy or CONSULT

FLOWSERVE, if necessary.

Damaged bearings due to contamination.

Check contamination source and replace damaged

bearings.

C. MOTOR ELECTRICAL PROBLEMS

Wrong direction of rotation.

Reverse 2 phases at motor terminal box.

Motor running on 2 phases only.

Check motor terminal box connections and voltage.

Loading...

Loading...