Logix™ 3800zb Digital Positioner FCD AIIOM001030_EN 02/23

flowserve.com 52

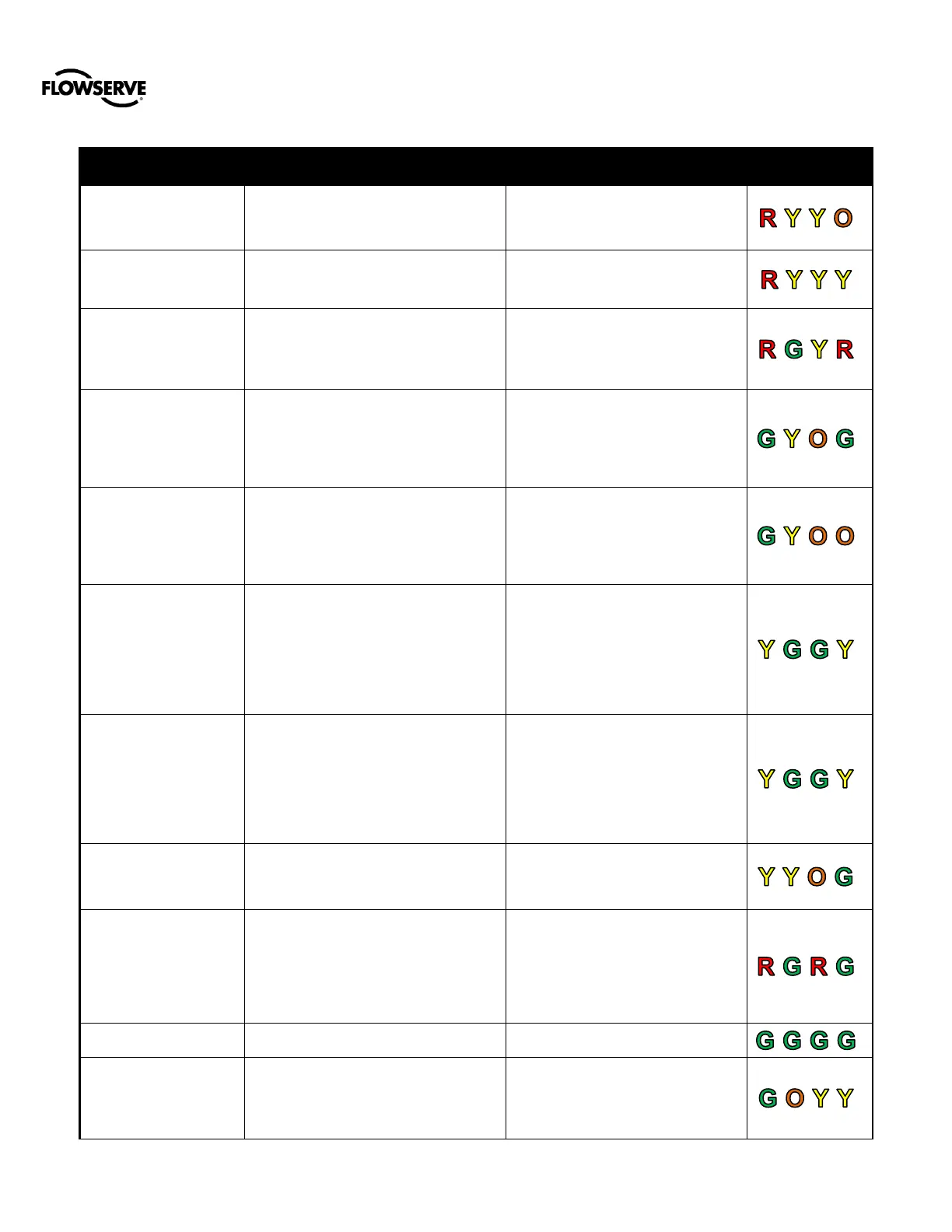

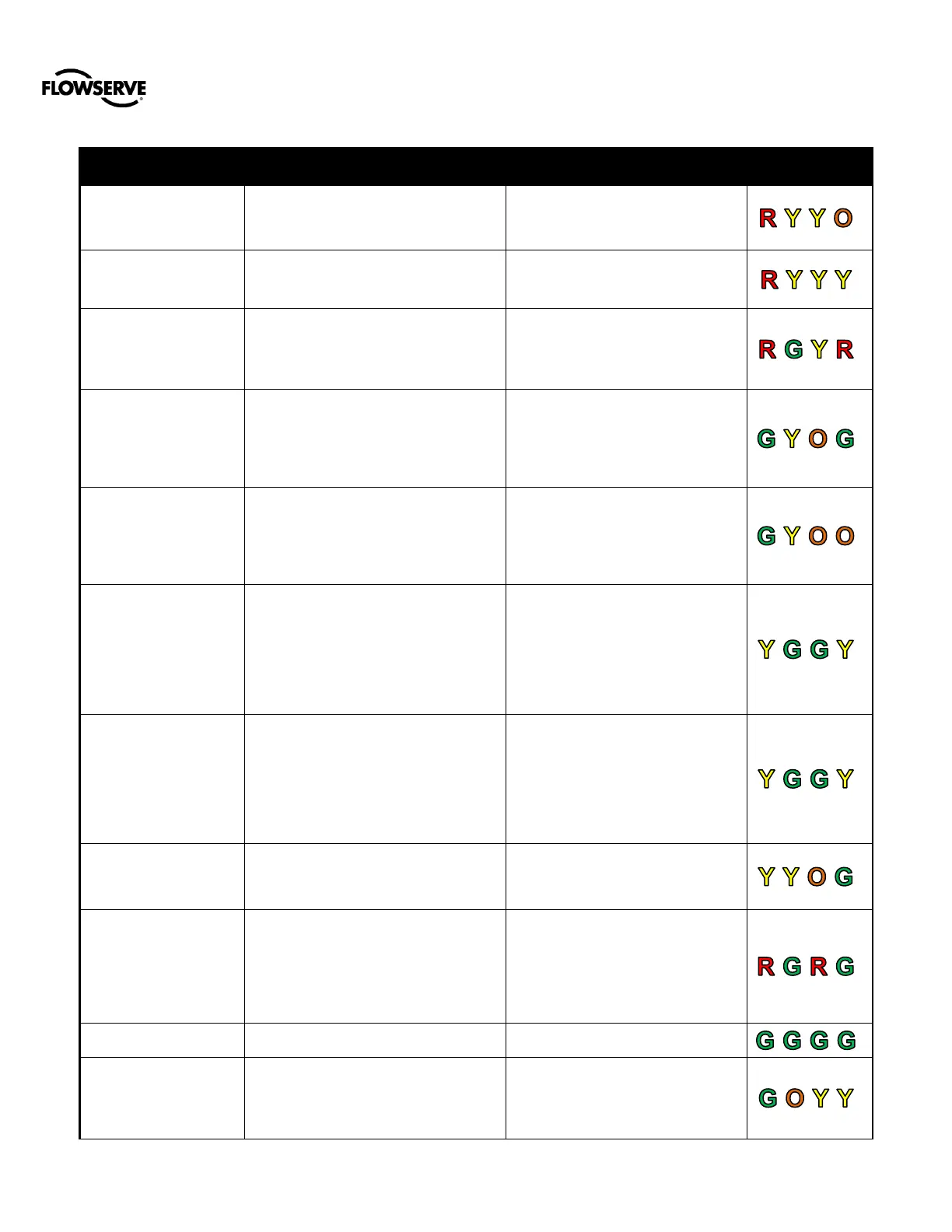

The Analog Output circuit is not

producing the expected output current.

Check AO loop wiring and ensure

adequate compliance voltage.

Replace electronics assembly if the

error persists.

Analog Output No Loop

Power

The Analog Output terminals have no

loop power. The positioner previously

detected power on the terminals.

Check terminal connection. Mask

the alarm if the circuit is not used.

Analog Output Range

Too Small

During a Analog Output calibration the

difference between the milliamp signal

at 0% and the milliamp signal at 100%

was too small.

Recalibrate making sure to use a

larger difference between signal

limits. This notification can be

cleared by briefly pressing the

QUICK-CAL button.

An Analog Output Calibration has been

started using the buttons (not LCD)

and the positioner is waiting for the

user to adjust the output current to 0%

via the I and III Buttons, then press the

QUICK-CAL button to accept.

Complete the calibration.

An Analog Output Calibration has been

started using the buttons (not LCD)

and the positioner is waiting for the

user to adjust the output current to 0%

via the I and III Buttons, then press the

QUICK-CAL button to accept.

Complete the calibration.

The bellows cycle limit has been

exceeded. The bellows may be

reaching the end of its fatigue life.

Each cycle represents two reversals of

the direction of bellows movement.

The cycle counting criterion and count

limit are set by the user to track the

usage of the valve.

Follow routine procedures for

maintenance when the limit is

reached such as checking bellows

for cracking or leaking. After

maintenance, reset the cycle

accumulator.

The bellows cycle limit has been

exceeded. The bellows may be

reaching the end of its fatigue life.

Each cycle represents two reversals of

the direction of valve movement. The

cycle counting criterion and count limit

are set by the user to track the usage

of the valve.

Follow routine procedures for

maintenance when the limit is

reached such as checking bellows

for cracking or leaking. After

maintenance, reset the cycle

accumulator.

One of the three buttons (internal or

external) is stuck in the on state.

Manipulate the buttons to attempt to

unstick them. Clean the buttons

with soft moist cloth to prevent

buildup of debris.

A factory reset was performed and the

positioner has not yet been calibrated.

The unit will not respond to commands

and will remain in the failsafe position

until a calibration is successfully

completed.

Perform a Stroke Calibration

(QUICK-CAL) by holding the

QUICK-CAL button down for 3

seconds, or perform a Pressure or

Friction calibration if desired. See

section 9, Operation – Calibration

And Control for warnings.

The last calibration succeeded.

Blink code will terminate

automatically.

The user has selected a combination of

key presses (Hot Key) that initiates a

calibration. The positioner is waiting for

the user to select the type of calibration

to run.

Refer Appendix F – Hot Keys to see

the calibration options.

Loading...

Loading...