Logix™ 3800zb Digital Positioner FCD AIIOM001030_EN 02/23

flowserve.com 12

5 INSTALLATION - TUBING

5.1 Direct Mount

After mounting to the actuator, tube the 4-Way valve block port

connections to the actuator using the appropriate fitting

connectors. For best performance, use 10 mm (3/8 inch)

tubing for 645 square cm (100 square inches) actuators or

larger.

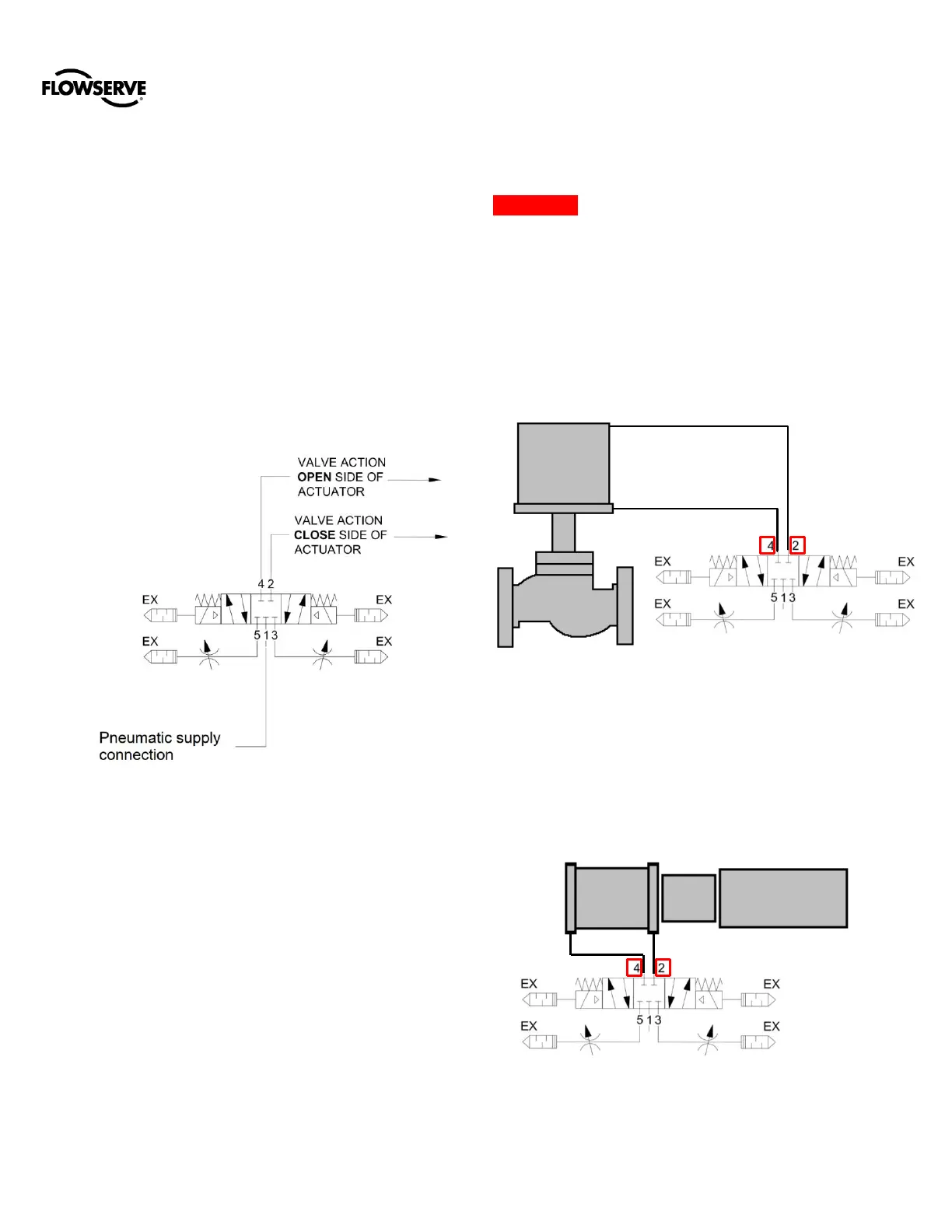

5.2 Determine Gas Supply Action

Connections using a 4-Way valve block for actuator control,

are shown in Figure 6.

Figure 6: 4-Way valve actuator connection

When a pneumatic supply is present at port “1”, and the

solenoid for port “4” is energized, port “4” delivers gas.

Typically, the tubing from port “4” is connected to the side of

the actuator that results in the gas compressing the actuator

spring. When tubed this way, the spring is designed to return

the valve to the fail-safe state should supply gas or power to

the unit fail or be turned off.

Tube the port labeled “4” to the side of the actuator that must

receive gas to begin moving away from the fail-safe state.

If gas from “4” should open the valve, set the Air Action

configuration DIP switch on the positioner to Air-to-Open,

otherwise set it to Air-to-Close. The Air-to-Open and Air-to-

Close selection is only a reflection of the tubing. When

selecting air action during configuration, the selection tells the

control which way the actuator was tubed.

If the valve is double acting, port the valve labeled “2” to the

other side of the actuator, otherwise plug port “2”.

DANGER: Proper tubing orientation is critical for the

positioner to function correctly and have the correct failure

mode. The backward tubing could cause an unsafe failure

mode.

Example: Tubing Linear Double-Acting Actuators

For a linear air-to-open actuator, the tubing from port “4” is

connected to the bottom side of the actuator (closest to the

valve). Tube the “2” port of the positioner to the top side of the

actuator. See Figure 7: Linear, Double Acting, Air to Open. For

a linear air-to-close actuator the tubing configuration is

reversed.

Figure 7: Linear, Double Acting, Air to Open

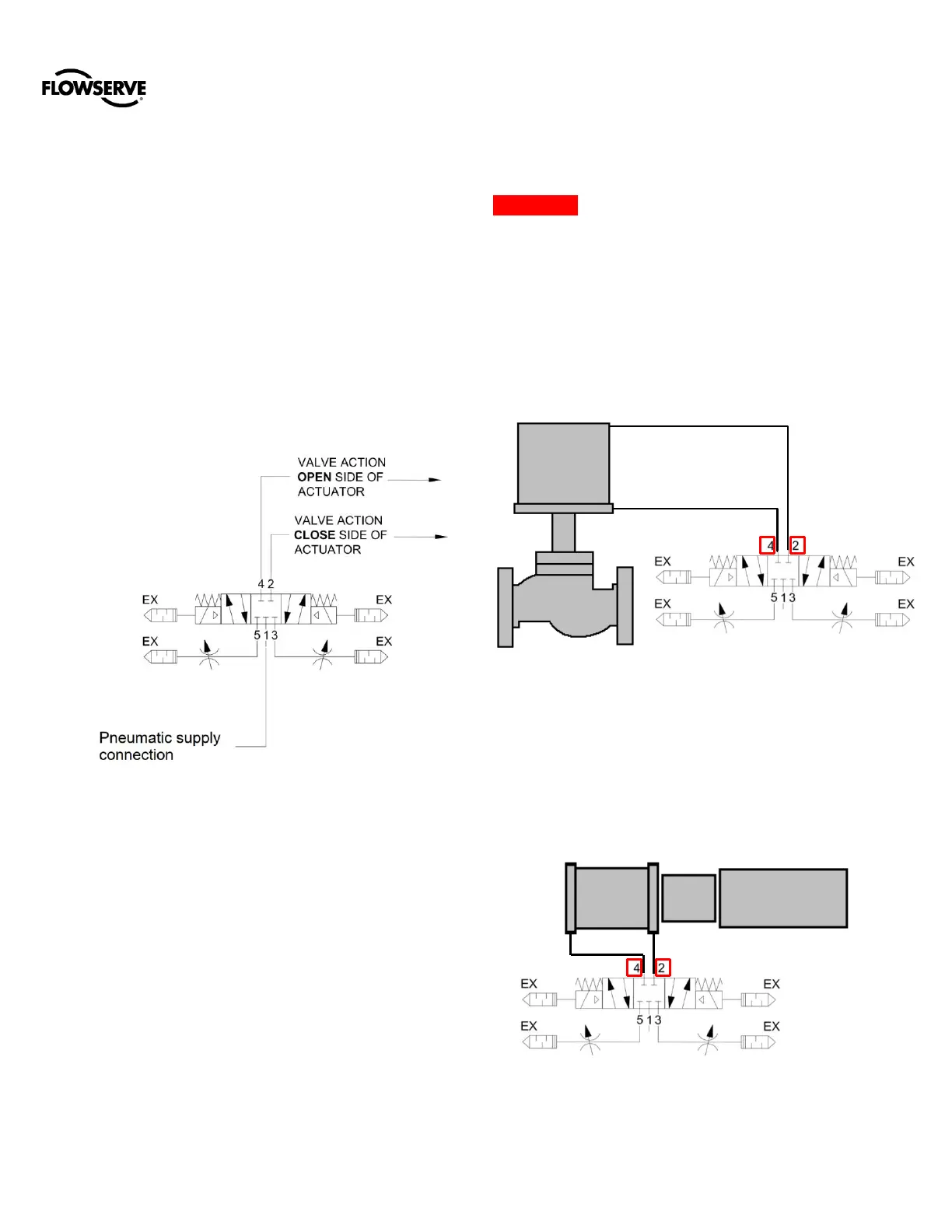

Example: Rotary Double-Acting Actuators

For a rotary actuator, route tubing from Port “4” to the far side

of the actuator and tubing from port “2” to the side of the

actuator closer to the transfer case. Follow this tubing

convention regardless of air action. On rotary actuators, the

transfer case orientation determines the air action. See Figure

8: Rotary, Double Acting, Air to Open.

Figure 8: Rotary, Double Acting, Air to Open

Example: Tubing Single-Acting Actuators

Loading...

Loading...