For single-acting actuators, tubing for port “4” is always to the

pneumatic side of the actuator regardless of air action. Port “2”

is plugged. See Figure 9: Linear, Single Acting, Air to Open.

Figure 9: Linear, Single Acting, Air to Open

5.3 Connect Supply Port

In applications where the supply pressure is higher than the

maximum actuator pressure rating of the supply, a regulator is

required to lower the pressure to the actuator’s maximum

rating.

DANGER: Exceeding the maximum actuator supply

pressure may cause the actuator to explode, causing death,

injury or property damage.

5.4 Purging

Purging allows the non-pressurized side of a single acting

actuator to fill with clean exhaust gas instead of moist

atmospheric air. This configuration helps prevent corrosion of

actuator components in harsh environments. Figure shows

the purging configuration. Contact your local FLOWSERVE

Representative for more information regarding the purging

option.

Figure 10: Purging

5.5 Venting

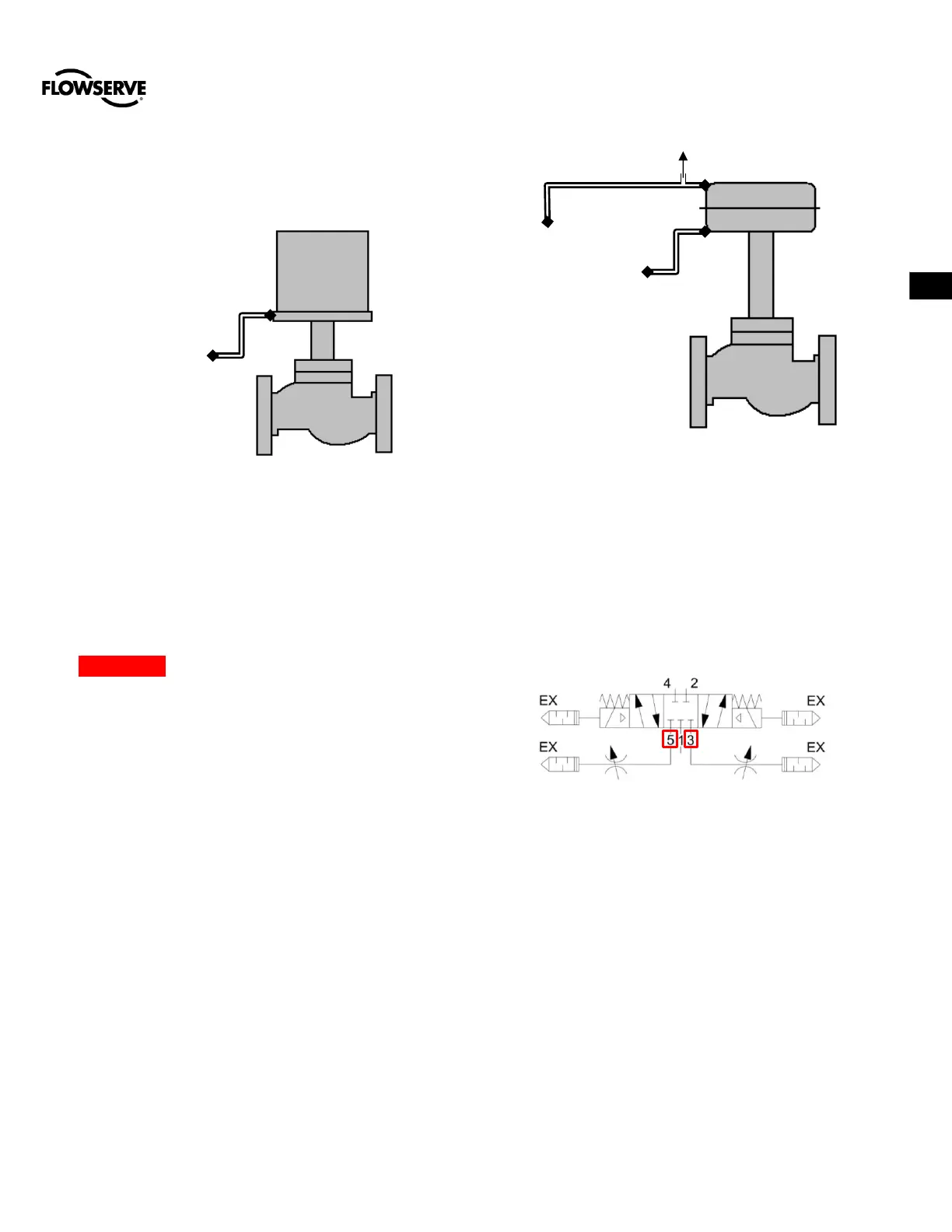

Venting for the Logix 3800zb controlled 4-Way valve block

happens at ports “3” and “5” to the atmosphere. When supply

air is substituted with sweet natural gas, piping must be used

to route the exhausted natural gas to a safe environment.

Speed control valves may be installed at ports “3” and “5” to

adjust flow to the actuator. See Figure 11: Exhaust Vent

Figure 11: Exhaust Vent

Loading...

Loading...