Logix™ 3800zb Digital Positioner FCD AIIOM001030_EN 02/23

flowserve.com 36

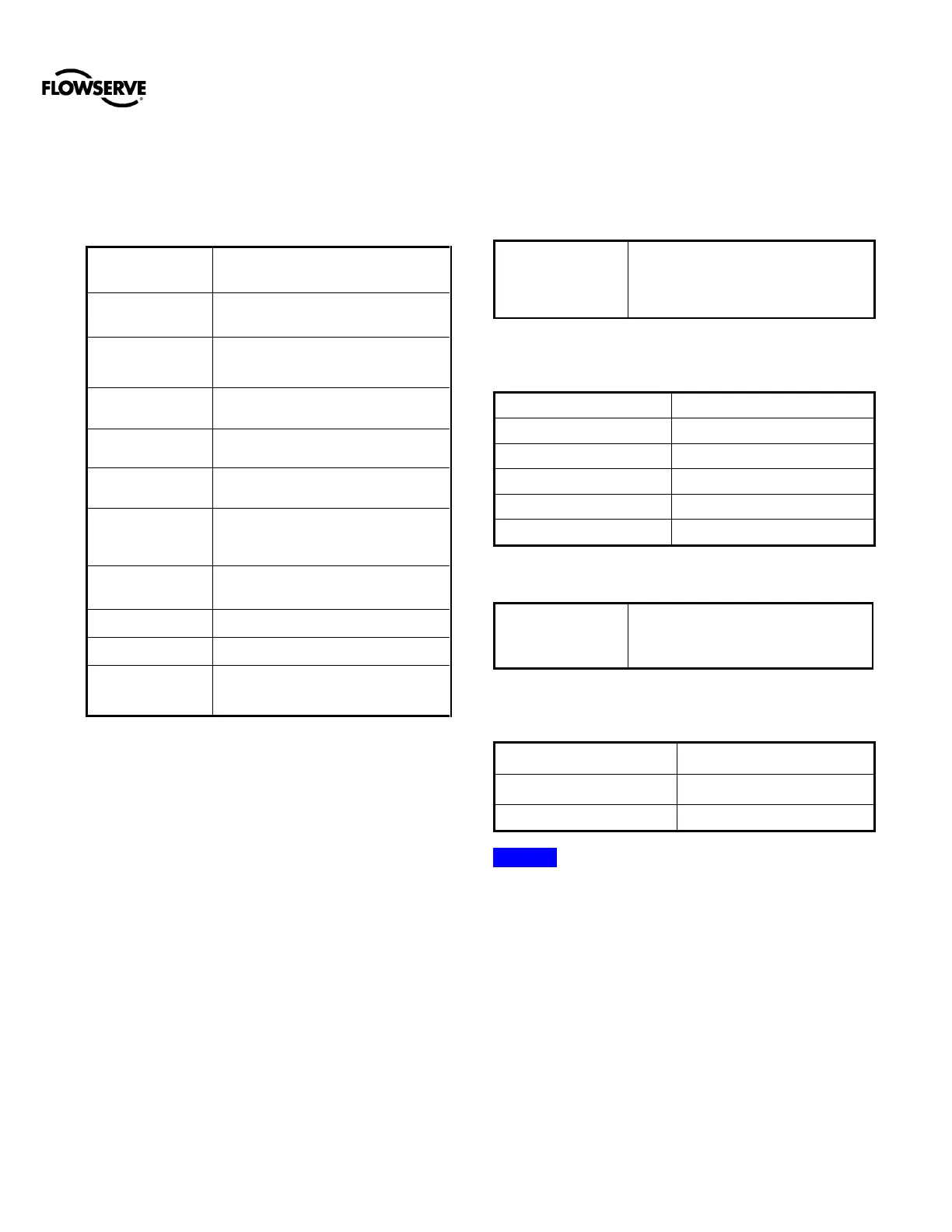

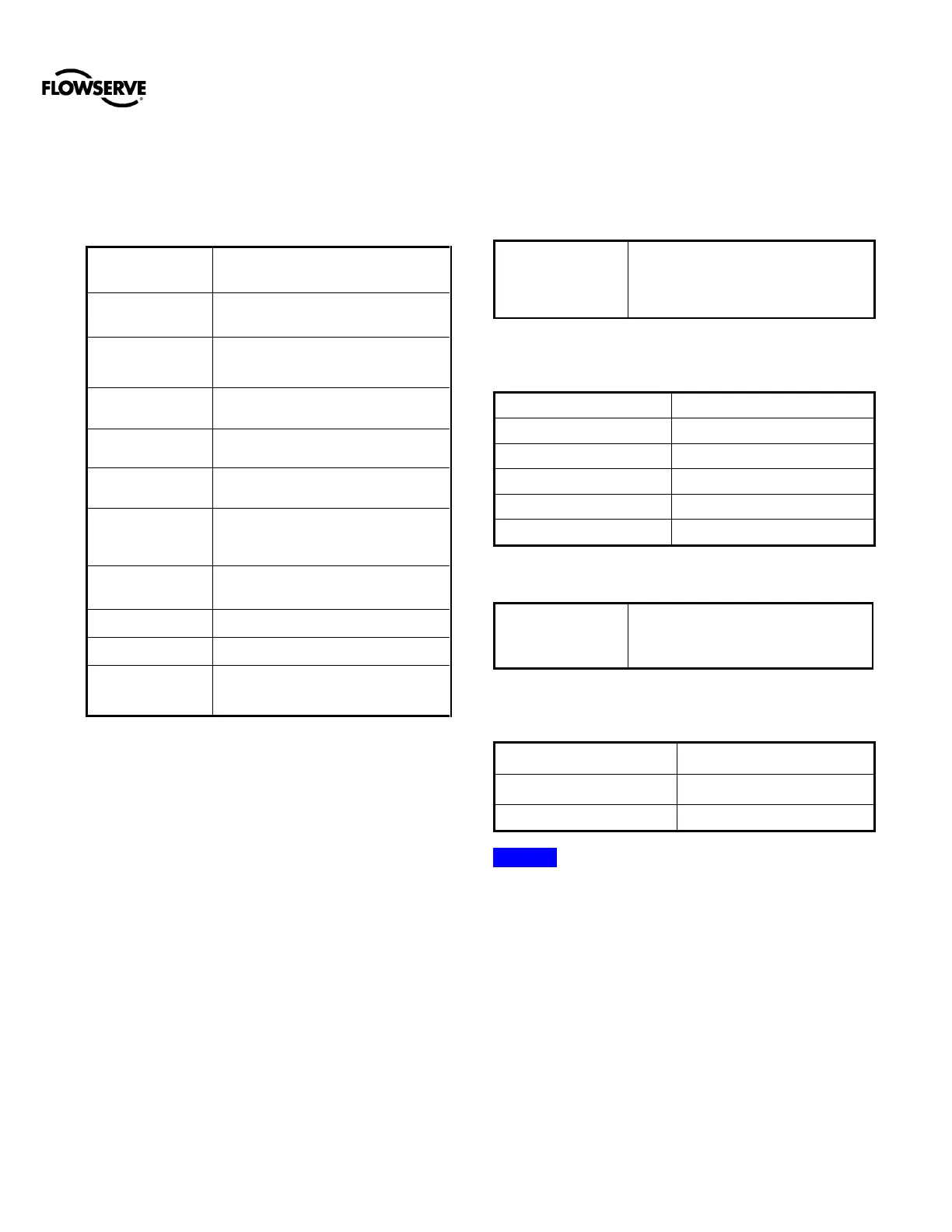

15 POSITIONER SPECIFICATIONS

15.1 Input Signal

Table 9: Input Signal (HART)

Two-wire, 4-20 mA

10.0 VDC plus line losses

Minimum Required

Operating Current

Power Interruption

Time Limit

After applying power for at least 1

minute, a 40 ms power interruption will

not cause the positioner to reset.

Time from the application of power to

begin controlling valve < 1.0 second.

HART protocol (Logix 382X- only)

Spring Terminal 24-16 AWG

Refer to the HART Field Communications

Protocol Application Guide, HART HCF

LIT

15.2 Pneumatic Supply

Table 10: Air Supply

Air, sweet natural gas, nitrogen, and CO2

are acceptable supply gasses. Sour natural

gas is not acceptable. For Type nA and

Type tb installation, only connect air or

inert gas to the air supply inlet.

15.3 Analog Output (HART)

Table 11: 4 to 20 mA Analog Output Specification

10.0 to 40 VDC, (24 VDC Typical)

-55 to 85°C (-67 to 185°F)

15.4 Stroke Output

Table 12: Stroke Output

Min 15°, Max 110° (with spring bias)

Max 180° (without spring bias)

60° recommended for linear applications.

15.5 Remote Mount Specifications

Table 13: Remote Mount Module Specifications

Use only with Logix™ Remote-

Mount Option device.

Max Cable and Tube Distance

30.5 m (100 ft) for ½” dia. tubing

9.1 m (30 ft) for ¼” dia. tubing

-55 to 124°C (-67 to 255°F)

NOTE: When using tubing near maximum lengths the

positioner performance may be degraded.

Loading...

Loading...