Reassembling the Actuator

To reassemble the cylinder actuator, refer to Figures 1 through 4:

1. All O-rings and the quad-seal should be replaced and lubricated

with a calcium complex grease (DuBois MPG-2 or equivalent).

Silicone O-rings must be lubricated with Magnalube-G lubricant or

equivalent.

2. Thoroughly clean all internal parts before beginning assembly.

Check the cylinder bore for scratches, pitting or worn areas.

Lubricate cylinder wall and all internal surfaces with the appropriate

lubricant.

NOTE: Applying a light coating of lubricant to the entire cylinder

bore, end cap and both sides of the piston enables smooth

operation and can help reduce corrosion.

3. Lubricate the outside of the replacement bushing if the stem

bushing has been removed. Press a new lower stem bushing into

the actuator stem bore in the yoke until it bottoms out. Press the

upper stem bushing into the bore until it is flush with the top of the

yoke (refer to Figures 1 or 2).

4. Replace the actuator stem O-ring and yoke O-ring.

NOTE: Item numbers correspond directly to actuator's bill of material. Refer to it for specific part numbers.

Parts listed change location upon reversing air action. No new parts are required.

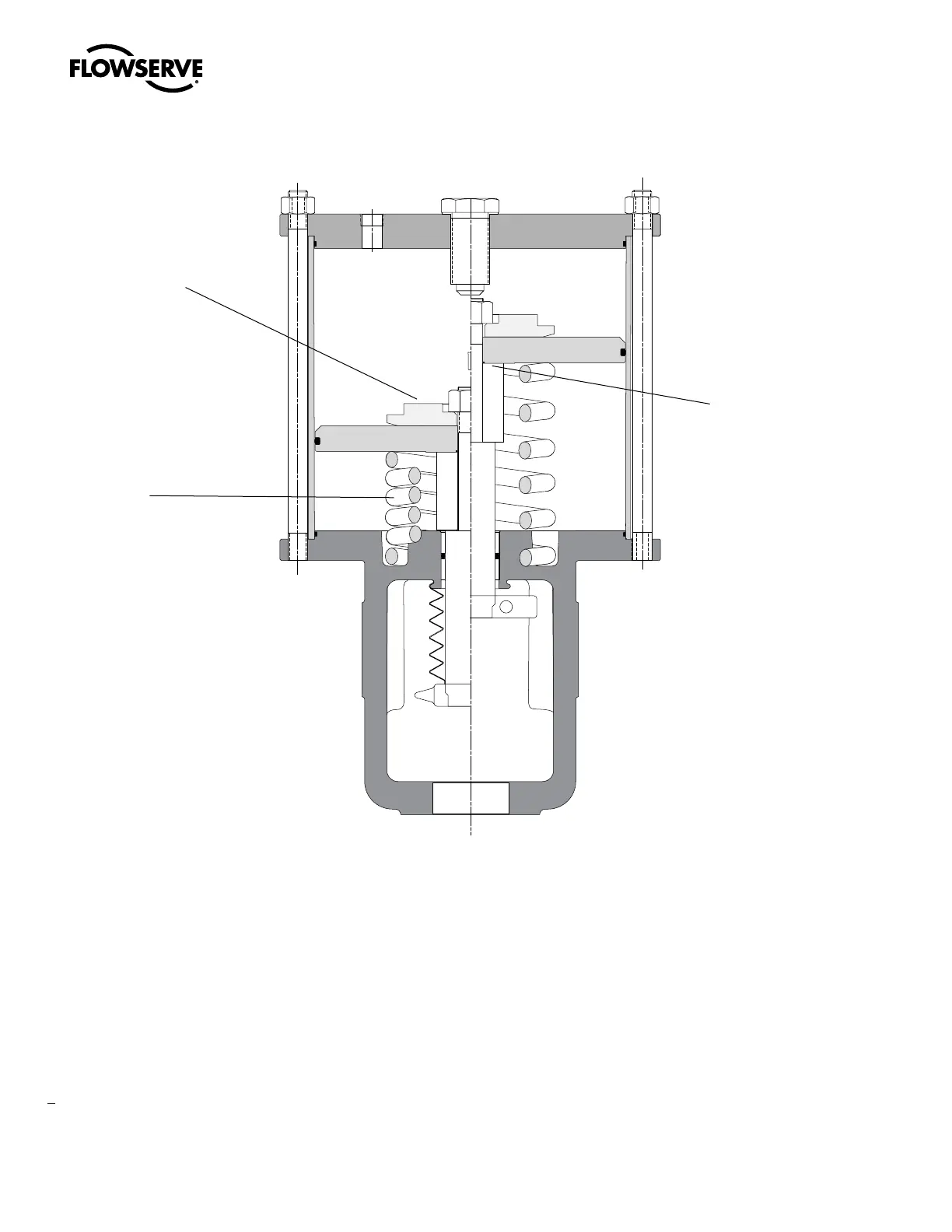

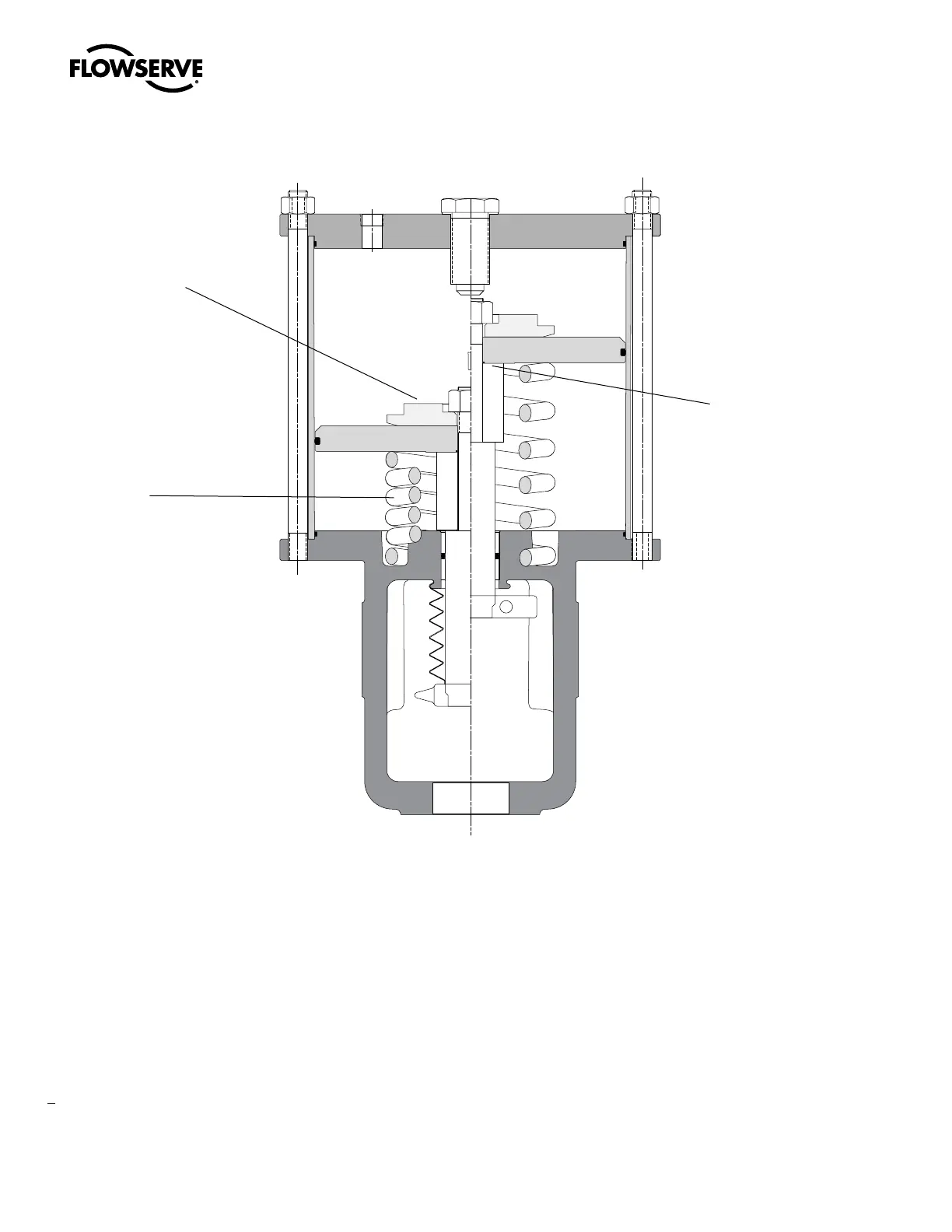

Figure 2: Air-to-extend Cylinder Actuator

Stem Spacer

(Item No. 228)

Spring Button

(Item No. 227)

Spring

(Item No. 229)

Valtek VL-C Spring Cylinder Linear Actuators FCD VLAIM054-01 – 06/13

6

Loading...

Loading...