What to do if unable to operate Flowserve Controller actuator by motor?

- TTeresa DavisAug 7, 2025

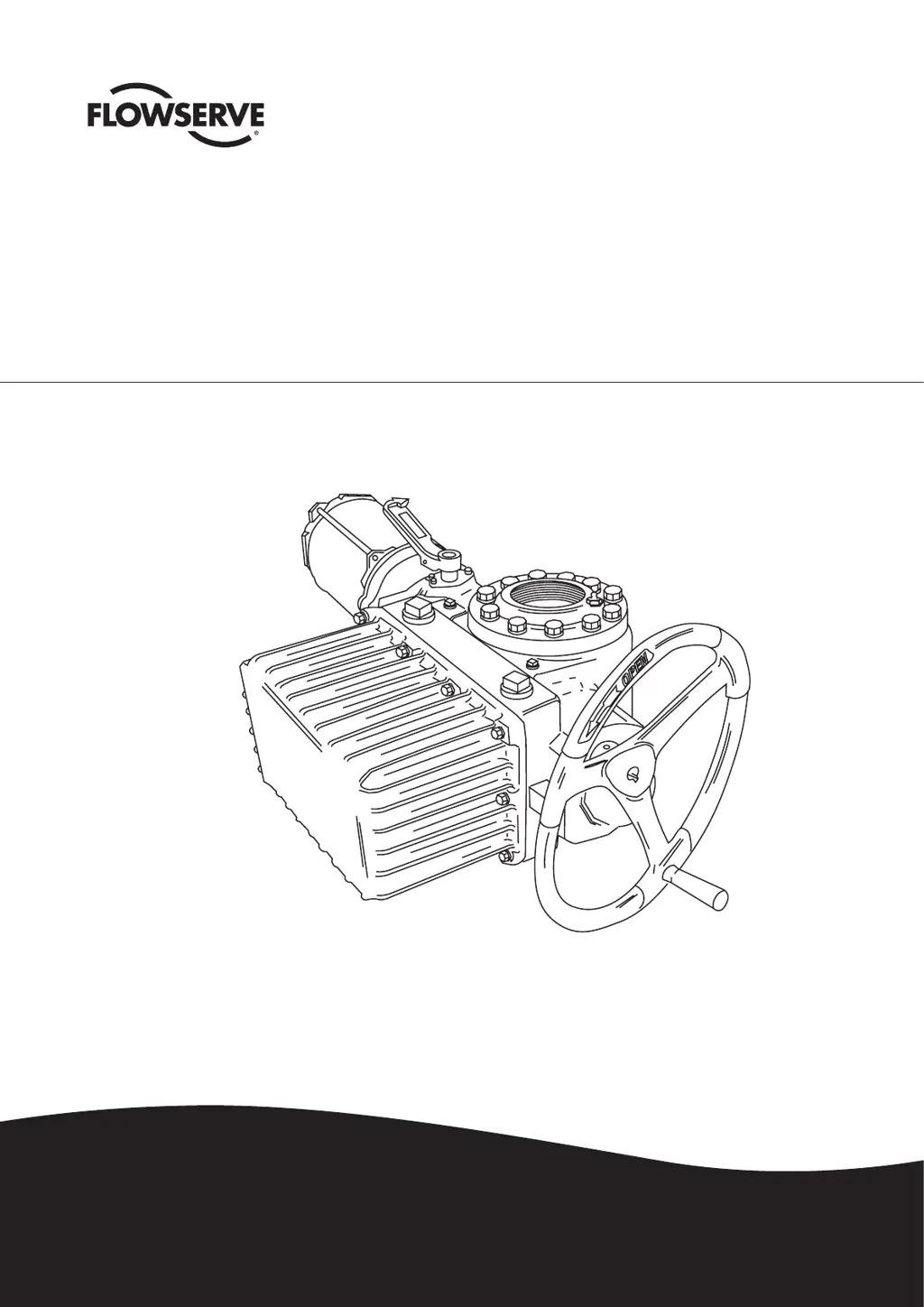

If you're unable to operate your Flowserve Controller actuator by motor, begin by verifying the motor power and control circuits for both supply and continuity. Then, check that the supply voltage matches the motor and controller's nameplate rating. If these are correct, measure the motor's amperage load. If the motor is stalled, immediately shut off the power and use the handwheel to manually move the valve.