Do you have a question about the Fluidmaster PRO Series and is the answer not in the manual?

Detailed diagram showing the top view of the cistern tank components.

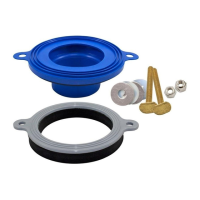

Diagram illustrating the various parts of the cistern system.

Instructions on how to open the cistern lid for access.

Guide on converting flush volume settings for different water usage.

Details on adjusting flush volumes for 6/3L or 9/4.5L systems.

Instructions for trimming or cutting the flush pipe to size.

Lubricate and connect the flush pipe to the toilet pan.

Attach coupling nut and seal, hand-tightening to connect flush pipe to outlet valve.

Initial step to turn on water and flush the supply line.

Connect the water supply line to the cistern, hand-tightening fittings.

Turn water on again and inspect for any leaks.

Flush cistern to check water level against the "WL" mark for proper flush.

Securing the cistern link into its designated position.

Position the seat on the link to mark cut points.

Use cutting lines on the link for necessary adjustments.

Insert seat bolt plates into the connection plate as guided.

Connect link, insert seat bolts, and hand-tighten nuts for link application.

Insert seat bolts into pan holes and hand-tighten nuts for non-link application.

Troubleshooting inlet valve issues by removing and checking for debris.

Diagnosing and fixing issues like the valve not turning on or off.

Caution against using bleach or chlorine cleaners that can damage components.

Details on product warranty, exclusions, and claims process.

Guidance on cleaning the product using soap and warm water.

| Material | Plastic |

|---|---|

| Adjustable Height | Yes |

| Anti-Siphon | Yes |

| Series | PRO Series |

| Type | Fill Valve |

| Compatibility | Most toilets |

| Installation | Easy |

| Warranty | Varies by model |

Loading...

Loading...