Maintenance

Calibration

3

3-7

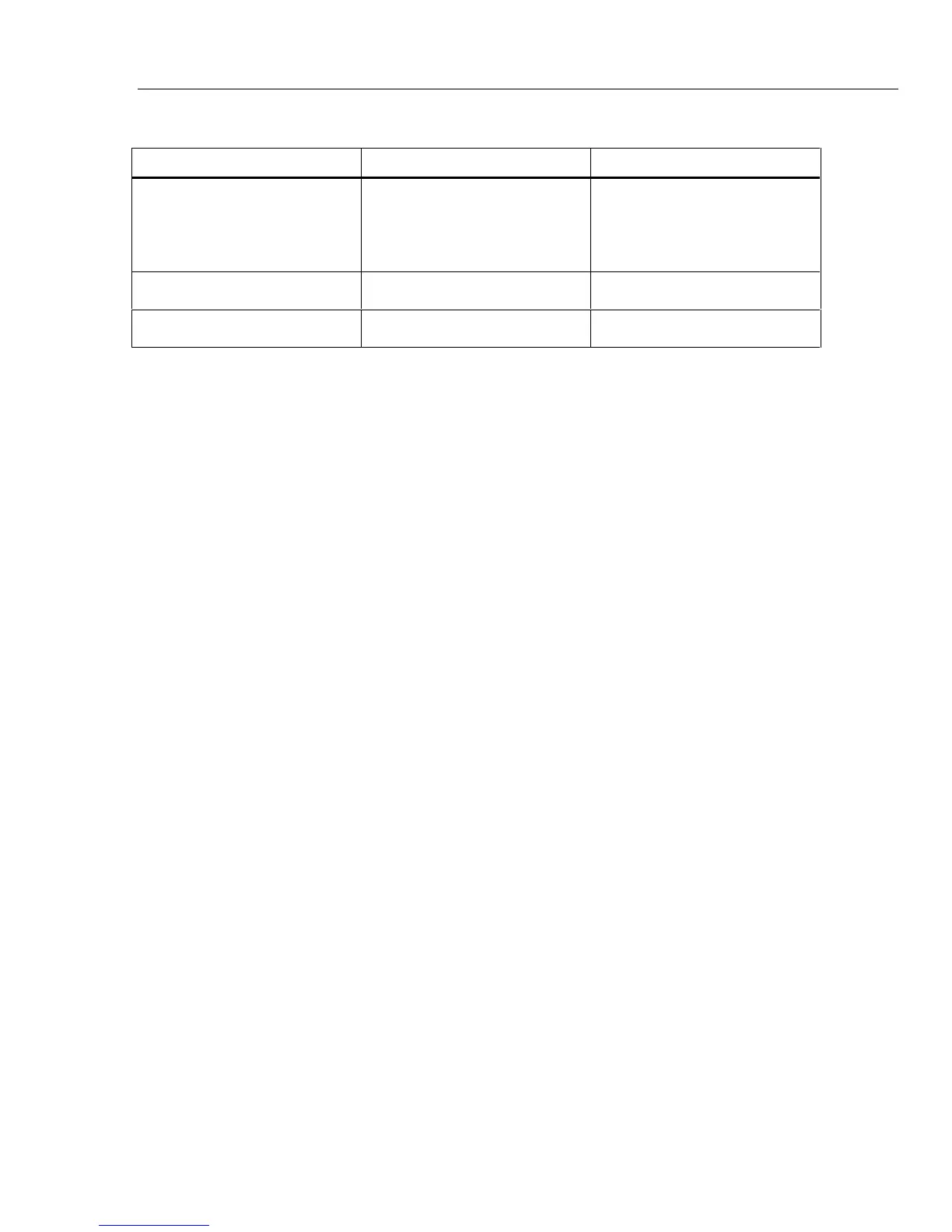

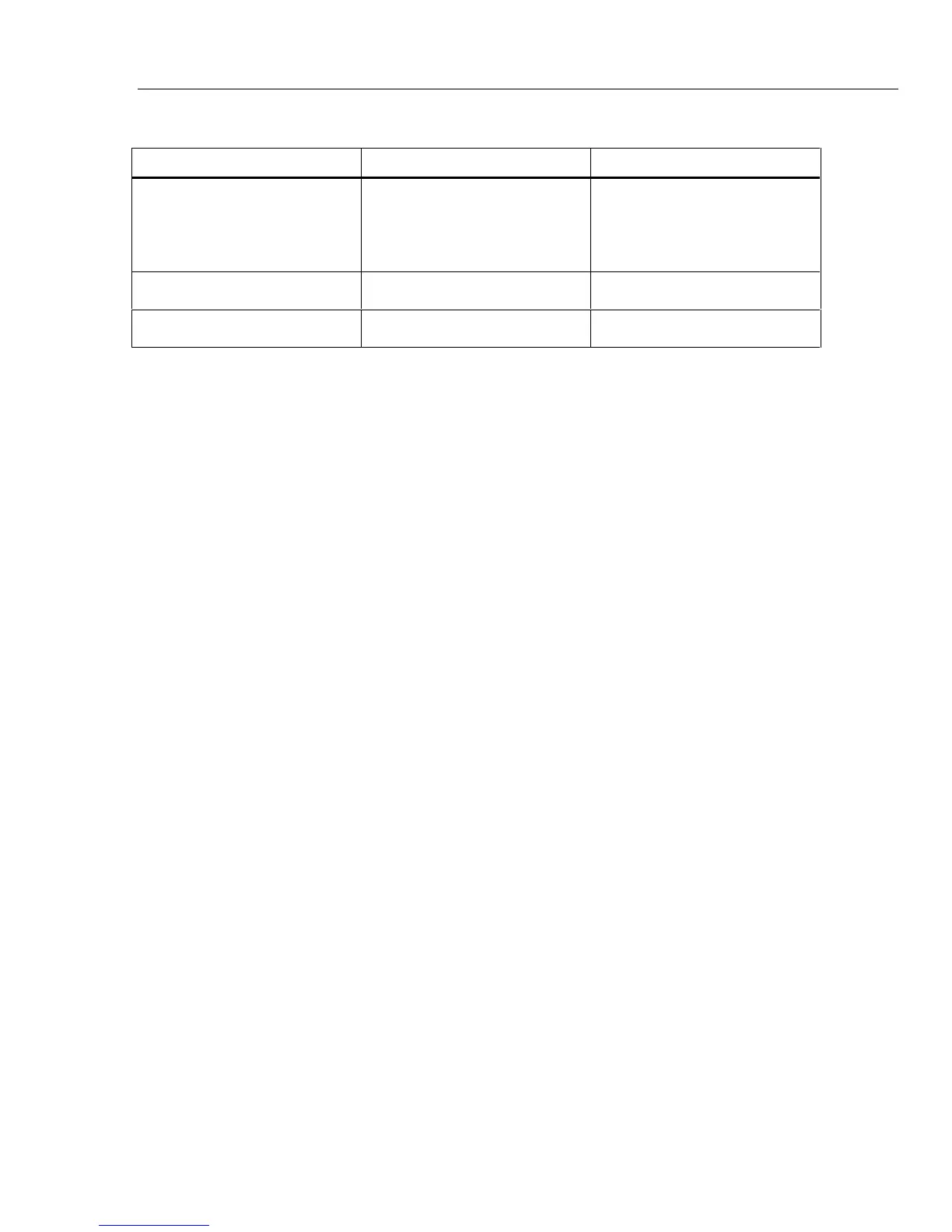

Table 3-1. Required Equipment

Equipment Minimum Specifications Recommended Model

DMM Calibrator DC Voltage: 0-600V

Accuracy: ±0.25%

AC Voltage: 0-600V

Accuracy: ±0.5%

Frequency: 50-400 Hz

Fluke Models (5700A, 5100B, or

equivalent)

Decade Resistor Resistance: 1.0-40 MΩ

Accuracy: ±0.25%

General Reisistance RDS-77B

and 41B

Decade Capacitor Capacitance: 0-1.000 µf

Accuracy: ±0.5%

GenRad 1412-BC

3. Apply the input from the appropriate source. The reading on the display should be

within the MINIMUM and MAXIMUM values shown in

4. Test the remaining functions and ranges.

3-5. Calibration

To ensure that the meter performs to specifications, calibrate it annually using the

following procedure:

1. Set the calibrator for 0V dc. Put the meter in the 4.000V dc range.

2. Connect the calibrator to the [+] and COM jacks on the Meter.

3. Apply an input of +4.000V dc +/-0.25% The meter display should read between

3.997-4.003V. If it does not, adjust R4 (see Figure 3-3) as follows.

To adjust R4:

1. Remove any input signals to the meter.

2. Remove the four screws on the back and separate the case bottom and case top.

Notice that when you do so the battery remains in the case bottom and power to the

meter is disconnected.

3. Observing correct polarity, connect a 9V battery to the battery contacts using easy

hook jumpers or alligator clip leads (see Figure 3-3).

NOTE

To avoid stretching or bending the battery contacts, connect leads to the

base of the contacts as shown in Figure 3-3.

4. Set the calibrator for 0V dc. Put the meter in the 4.000V dc range.

5. Connect the calibrator to the [+] and COM jacks on the Meter.

6. Apply an input of +4.000V dc +/-0.25%

7. Adjust R4 (see Figure 3-3) so that the meter display reads between 3.997-4.003V.

Loading...

Loading...