Installation

Install the pump

WARNING:

• Before installing the pump, check that the cable and cable entry have not been

damaged during transportation.

• Make sure that the pump cannot roll or fall over and injure people or damage property.

• Do not install CSA-approved products in locations that are classified as hazardous in the

national electric code, ANSI/NFPA 70-2005.

NOTICE:

• Never force piping to make a connection with a pump.

These requirements apply:

• Use the pump dimensional drawing in order to ensure proper installation.

• Provide a suitable barrier around the work area, for example, a guard rail.

• Check the explosion risk before you weld or use electric hand tools.

• Remove all debris from the inlet piping system before you install the pump.

Sedimentation prevention

In order to avoid sedimentation when the pumped liquid contains solid particles, the

velocity of the liquid in the discharge line must exceed a certain value. Choose applicable

minimum velocity from the table, and choose proper dimension of the discharge line

accordingly.

Mixture Minimum velocity, meter per second (feet per second)

Water + coarse gravel 4 (13)

Water + gravel 3.5 (11)

Water + sand, particle size <0.6 mm (0.024 in.) 2.5 (8.2)

Water + sand, particle size <0.1 mm (0.004 in.) 1.5 (4.9)

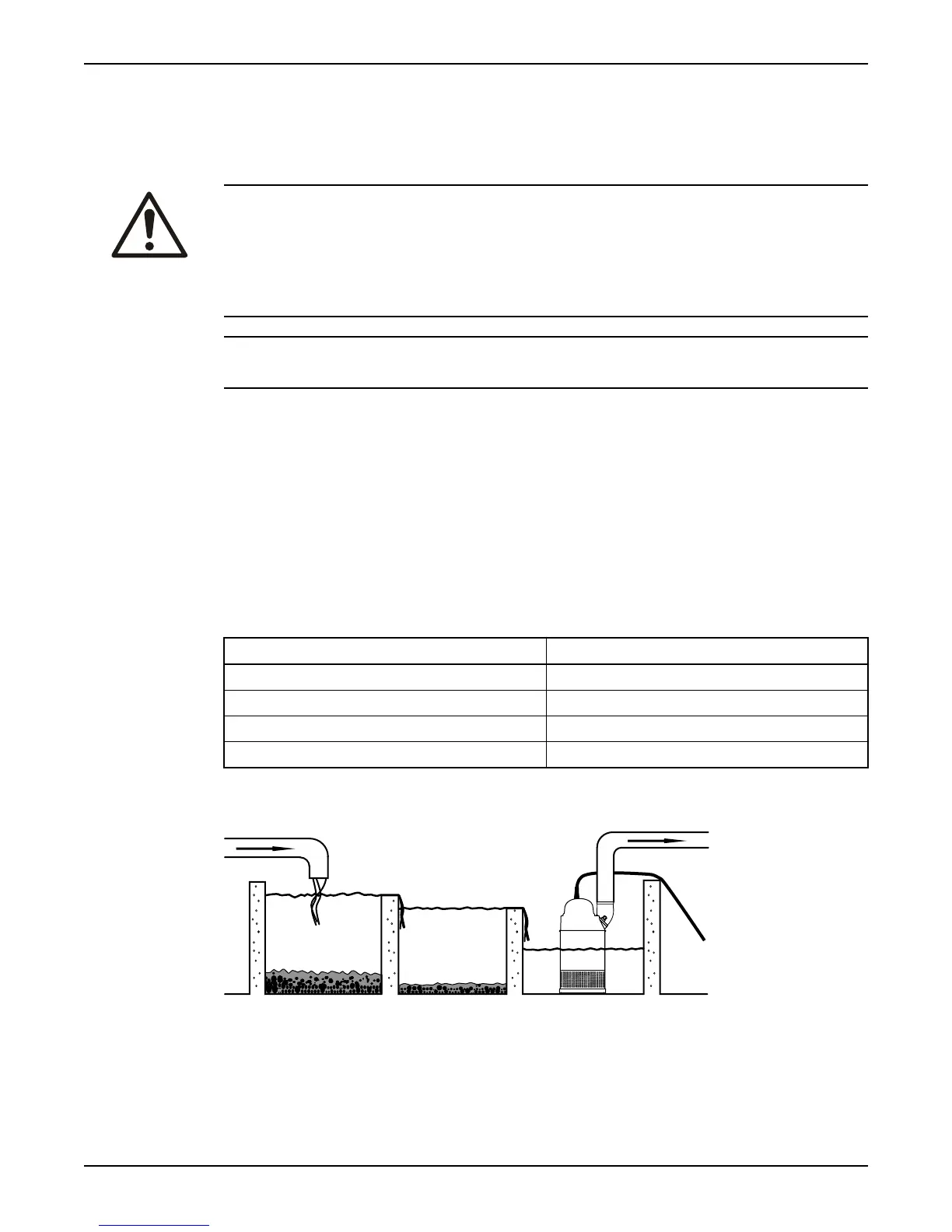

For more permanent installations with a heavily contaminated pumped liquid, a settling

pump-sump is recommended.

Figure 2: Settling pump-sump

Discharge line requirements

The discharge line can be run vertically or horizontally, but must be without sharp bends.

Installation

16 2125 Installation, Operation, and Maintenance Manual

Loading...

Loading...