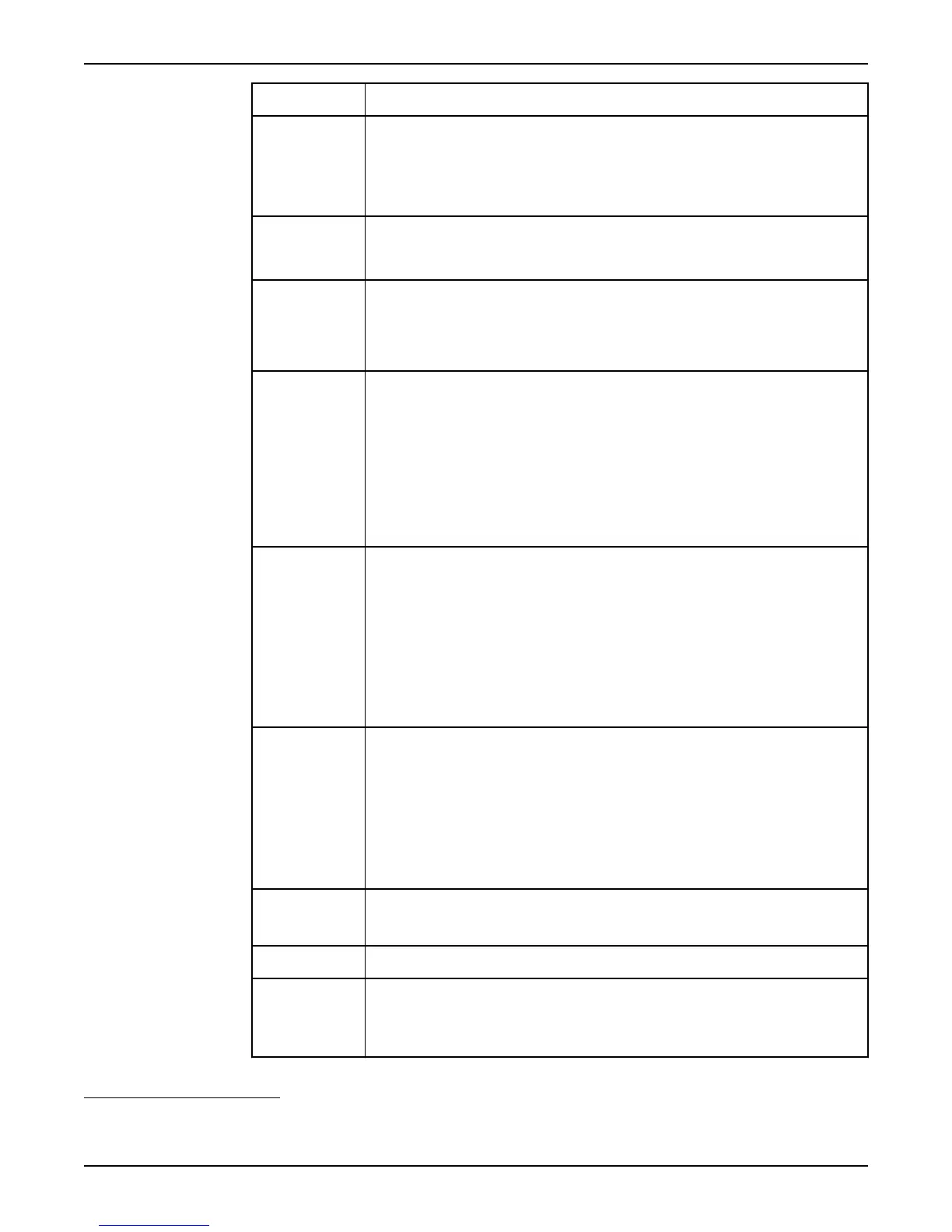

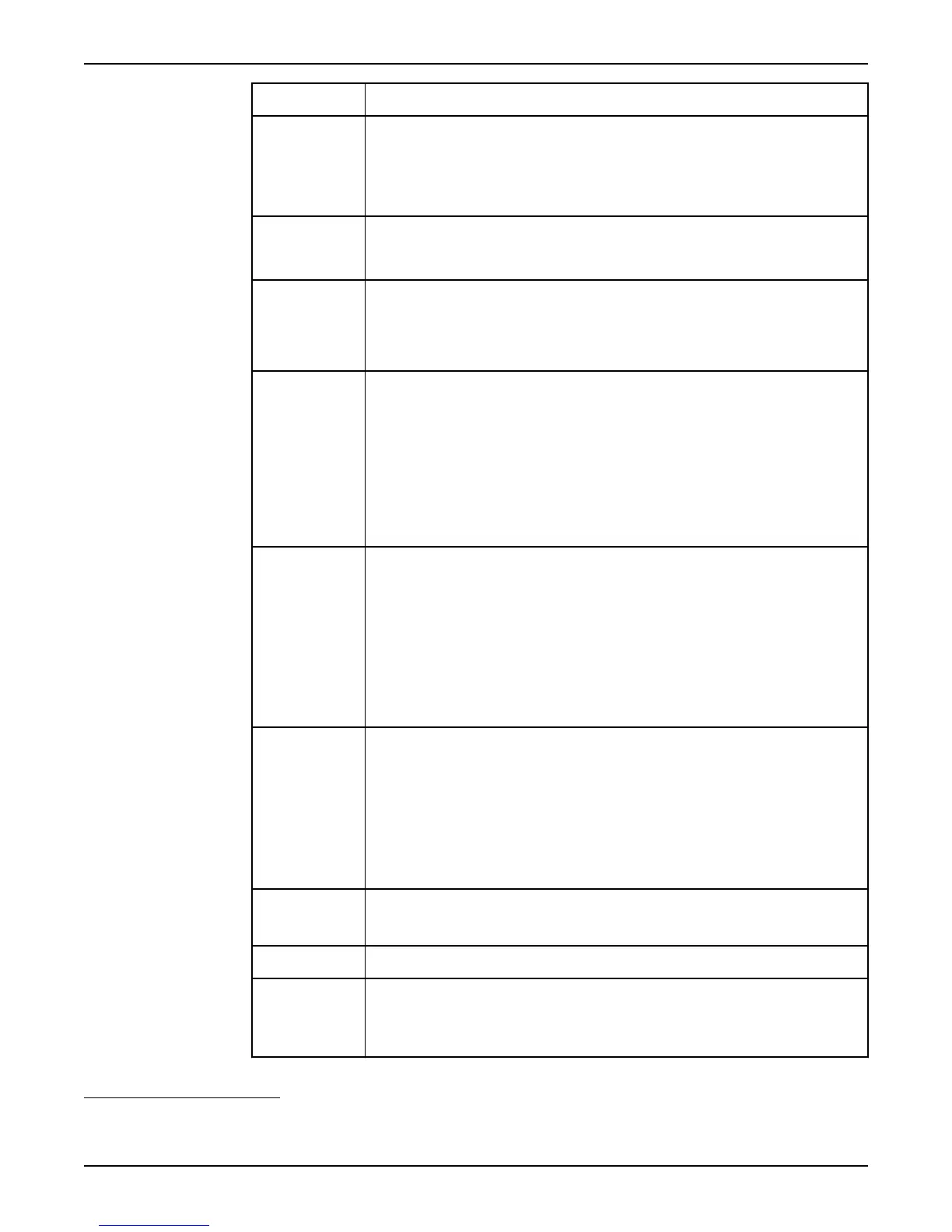

Service item Action

Visible parts on

the pump and

installation

1. Check that all screws, bolts, and nuts are properly tightened.

2. Check the condition of lifting handles, eyebolts, ropes, chains, and wires.

3. Check for worn or damaged parts.

4. Adjust and/or replace if necessary.

Pipes, valves, and

other peripheral

equipment

1. Check for worn or damaged parts.

2. Adjust and/or replace if necessary.

Pump casing and

impeller

1. Check for worn or damaged parts.

2. Adjust and/or replace if necessary.

Wear on the impeller or surrounding parts necessitates fine adjustments of the impeller

or replacement of worn parts. See Replace the impeller (page 34).

Oil Check the water and oil mixture as follows:

1. Insert a tube or hose into the oil hole.

2. Cover the top end of the tube.

3. Take up a little oil from the bottom.

(Air/oil mixture can be confused with water/oil mixture.)

4. If the mixture contains too much water, in other words if it is heavily emulsified

(creamlike) or if the water has settled out, then change the oil. See Change the

oil (page 33). Check again one week after changing the oil.

Cable entry

1. Check that the following requirements are met:

• The cable clamps must be properly tightened.

• The cable entry must be firmly tightened into its bottom-most position.

• The seal sleeve and the washers must conform to the outside diameter of the

cables.

2. Cut off a piece of the cable so that the seal sleeve closes around a new position

on the cable.

3. Replace the seal sleeve, if necessary.

Inspection

chamber

2

1. Drain all liquid.

2. If there is water in the stator casing, then do the following:

a. Check that the inspection screw is properly tightened.

b. Check that the O-ring is not damaged.

c. Check that the cable entry does not have any leakage.

3. If there is oil in the inspection chamber, then check that the inner mechanical

seal is not damaged. If necessary, contact an authorized service shop.

Cable

1. If the outer jacket is damaged, replace the cable.

2. Check that the cables do not have any sharp bends and are not pinched.

Cooling system Rinse and clean if the flow through the system has been partly restricted.

Level sensors or

other sensor

equipment

1. Check the functionality.

2. Repair or replace any damaged equipment.

3. Clean and adjust the equipment.

2

Regardless of individual applications, the inspection chamber should not be inspected less frequently than the intervals for normal

applications and operating conditions at media (liquid) temperatures <40°C.

Maintenance

32 2125 Installation, Operation, and Maintenance Manual

Loading...

Loading...