This welder has been engineered to give many years of trouble-free service providing that a few very

simple steps are taken to properly maintain it.

• Replace power cord, ground cable, ground clamp, or electrode assembly when damaged

or worn.

• Periodically clean dust, dirt, grease, etc. from your welder.

• Every six months, or as necessary, remove the cover panel from the welder and air-blow any

dust and dirt that may have accumulated inside the welder.

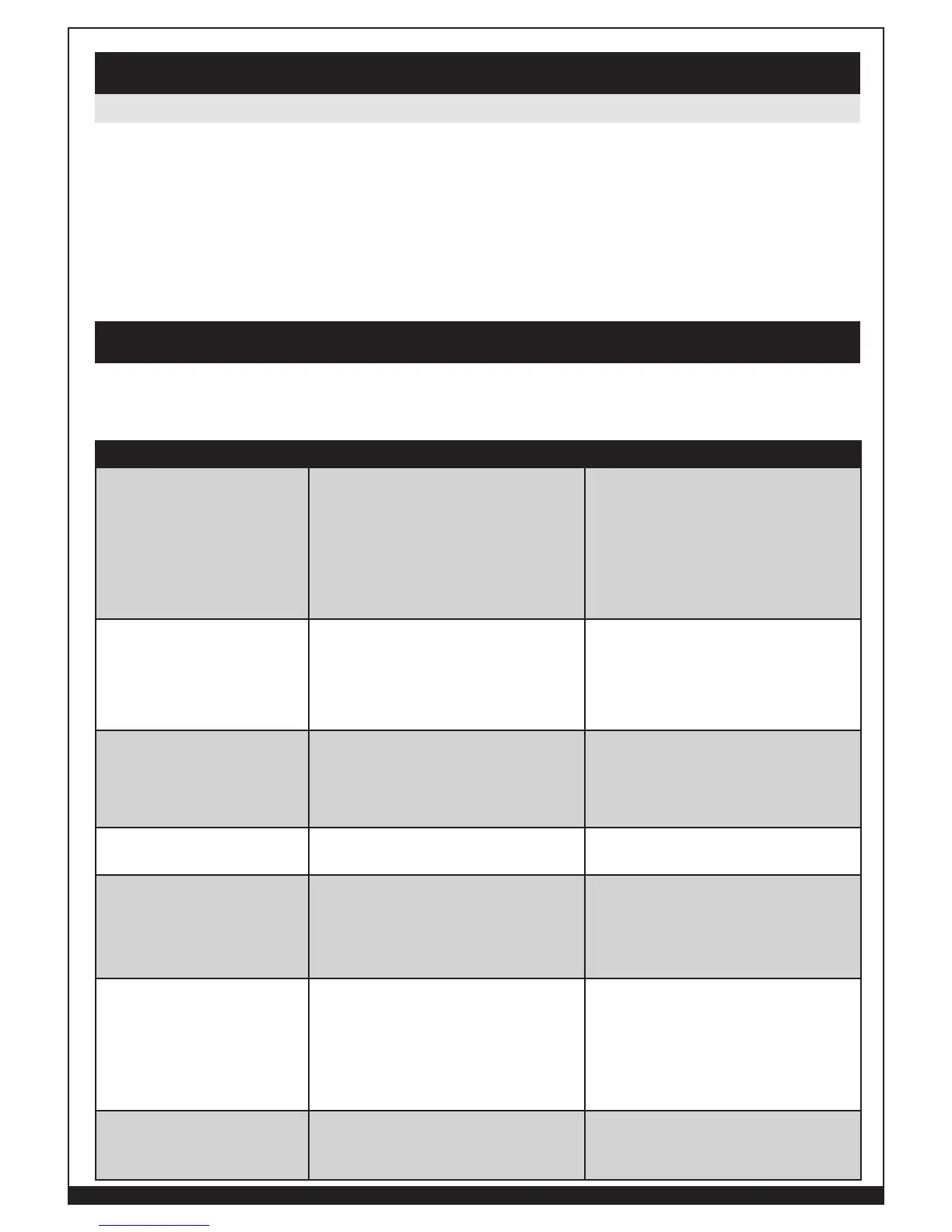

This chart will assist you in resolving common problems you may encounter. These are not all the possible

solutions.

PROBLEM POSSIBLE CAUSE POSSIBLE SOLUTION

Welder does not hum

when turned on

1. No power at receptacle

2. Broken or damaged power cord

3. Faulty switch

4. Faulty transformer

1. Check circuit and fuses or circuit-

breakers back at meter

2. Replace power cord

3. Switch needs to be replaced

4. Transformer needs to be

replaced

Welder humbs but will not

weld

1. Inadequate power at the

receptacle

2. Inadequate current at the arc

3. Poor connections at the welder

1. Check power supplies

2. Check ground clamp cable and

connection to work piece; check

electrode cable and clamp at

electrode

Welder gives shocks 1. Incorrect connections at power

cord or receptacle (hot wire

connected to ground terminal)

2. Welder wired to 3-phase current

1. Rewire power cord receptacle

2. Check power source

Welder heat setting difficult

to adjust

Dust or dirt moving inside

transformer

Clean shunt track

Welder overheats/blows

fuses

1. Fan blade not turning or obstructed

2. Fan turning too slowly - misaligned

bearings

3. Wrong amperage fuse in fuse box

1. Clear blade of obstruction and/or

replace fan motor

2. Replace fan motor & bearings

3. Replace with 50 amp or breaker

Arc hard to strike 1. Wrong type of electrode or

electrode too large

2. Base metal not grounded

properly

3. Voltage from power line low due

to heavy loads

1. Check electrode and verify size

and type of electrode for application

2. Verify grounding

3. Have power company verify

voltage and increase if possible

Bead too thin in places Uneven speed in moving electrode

across base metal

Slow down; try to maintain steady

rate of travel across the surface to

be welded.

Maintenance & Servicing

General Maintenance

Troubleshooting

Loading...

Loading...