Page 23

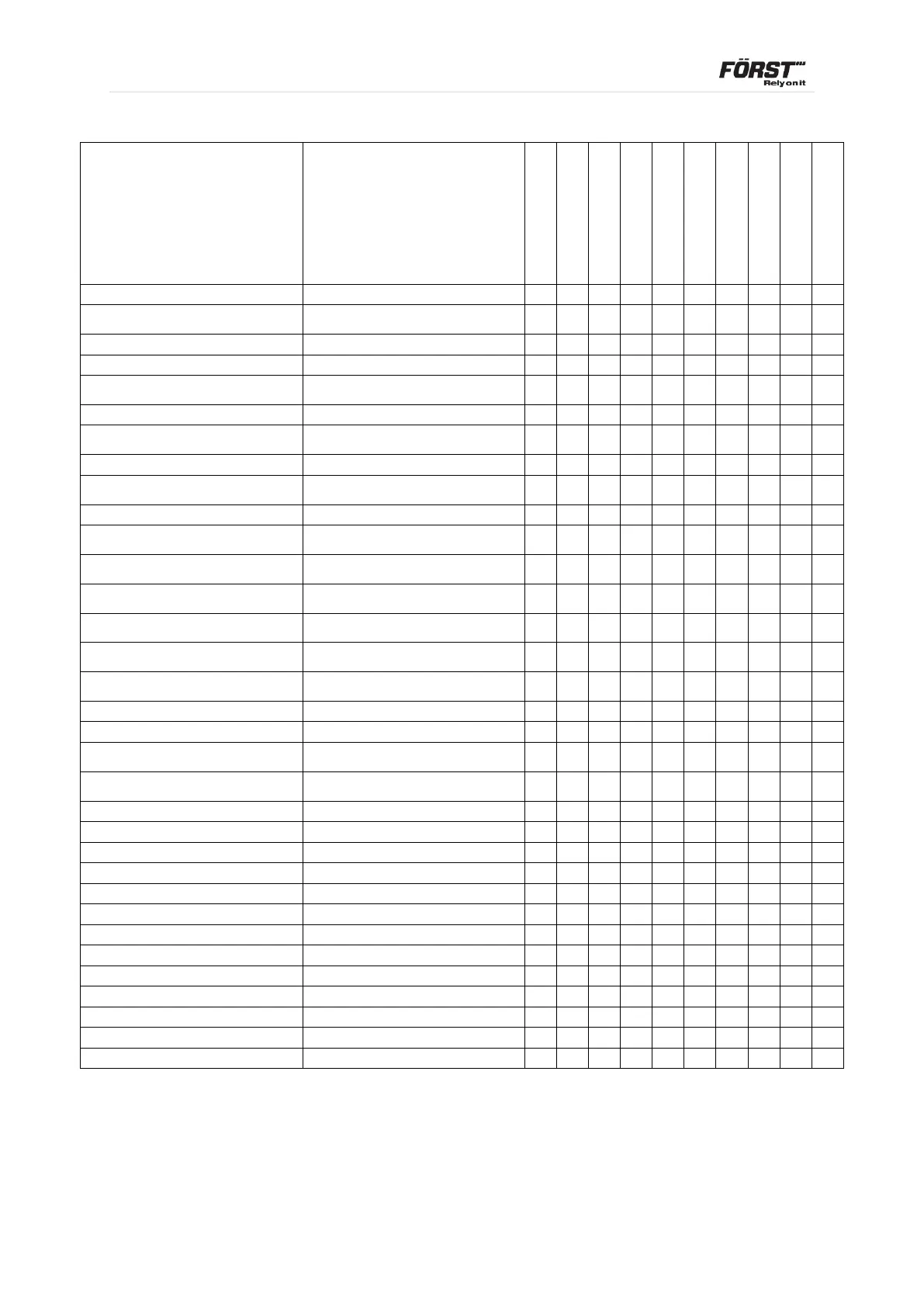

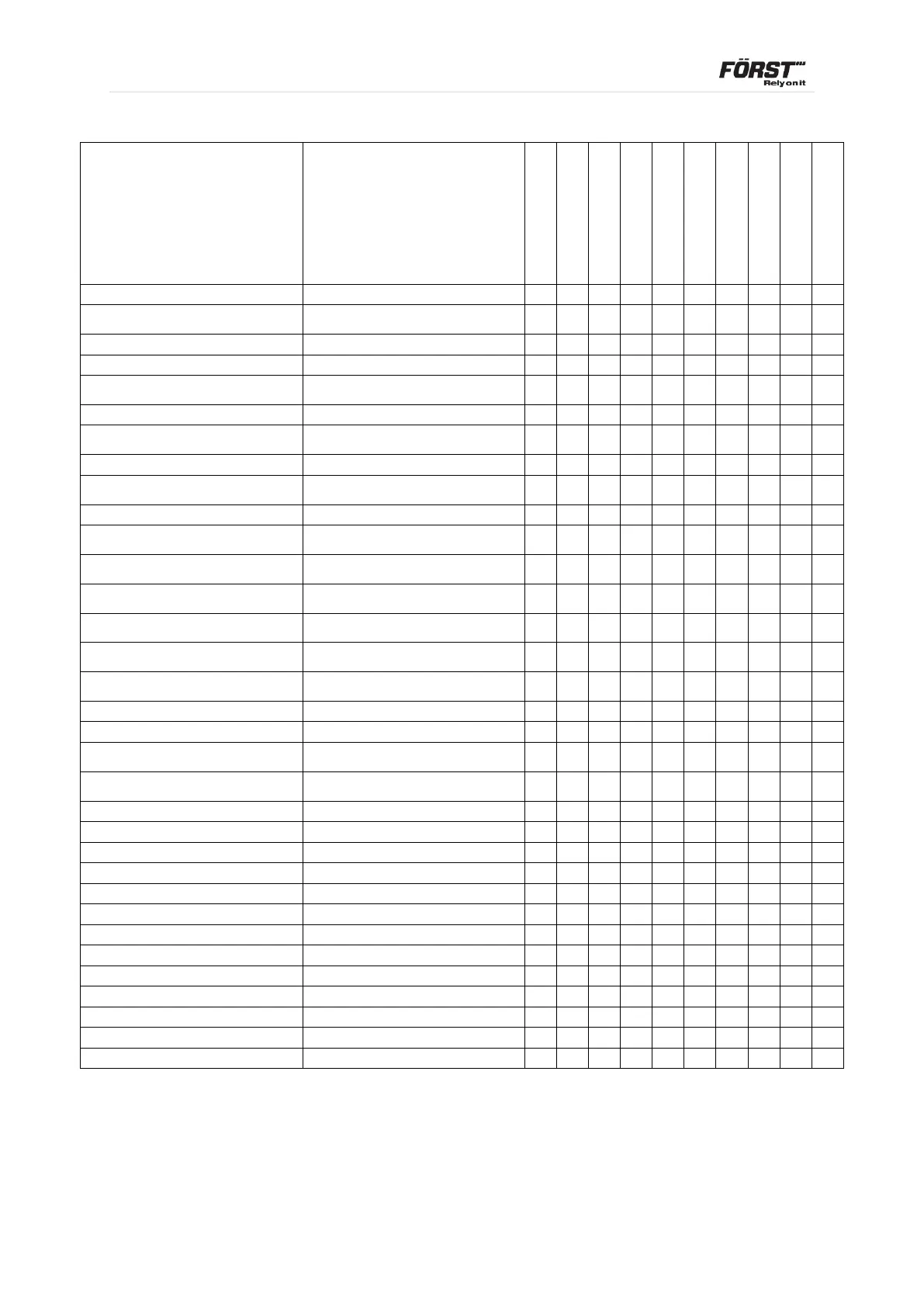

5.4 Service Schedule

Tighten hydraulic fittings

Check engine oil level & top up if

necessary

Visual check for fluid leaks

Grease bearings via central point on

control panel

Change hydraulic filter cartridge

Check brake adjustment (wheeled

only)

Check flywheel shaft bearings

Check cutting blade & anvil

condition, change if required

Replace hydraulic oil filter element

Check all engine components are

serviceable after break-in period

Check fuel hoses and clamp bands

Check feed roller tension springs &

replace if required

Check wear mark on towing hitch

(wheeled only)

Check wiring for damage & loose

connections

Check radiator hoses & clamp bands

Check feed roller bearings on motor

side

Replace bottom feed roller inner

brass bush

Drain water from fuel filter

Check and carry out forced Regen if

required

Check screen for fault codes,

investigate and report

Check cooling fan belt tension

Replace hydraulic oil filter element

Replace engine oil filter

Replace fuel filter element

Check coolant SG (-25°C or lower)

Drain and replace coolant

Drain and replace hydraulic oil

Loading...

Loading...