Page 30

5.10 Drive belt tension

The flywheel V belts must be checked for tension and condition. If any belt shows

signs of wear, surface damage, shredding, excessive glazing, or have been

stretched to their limit, they must be replaced. Multiple belt drives must have all belts

replaced at the same time. Belts that are too slack will cause poor cutting

performance, excessive belt and pulley wear.

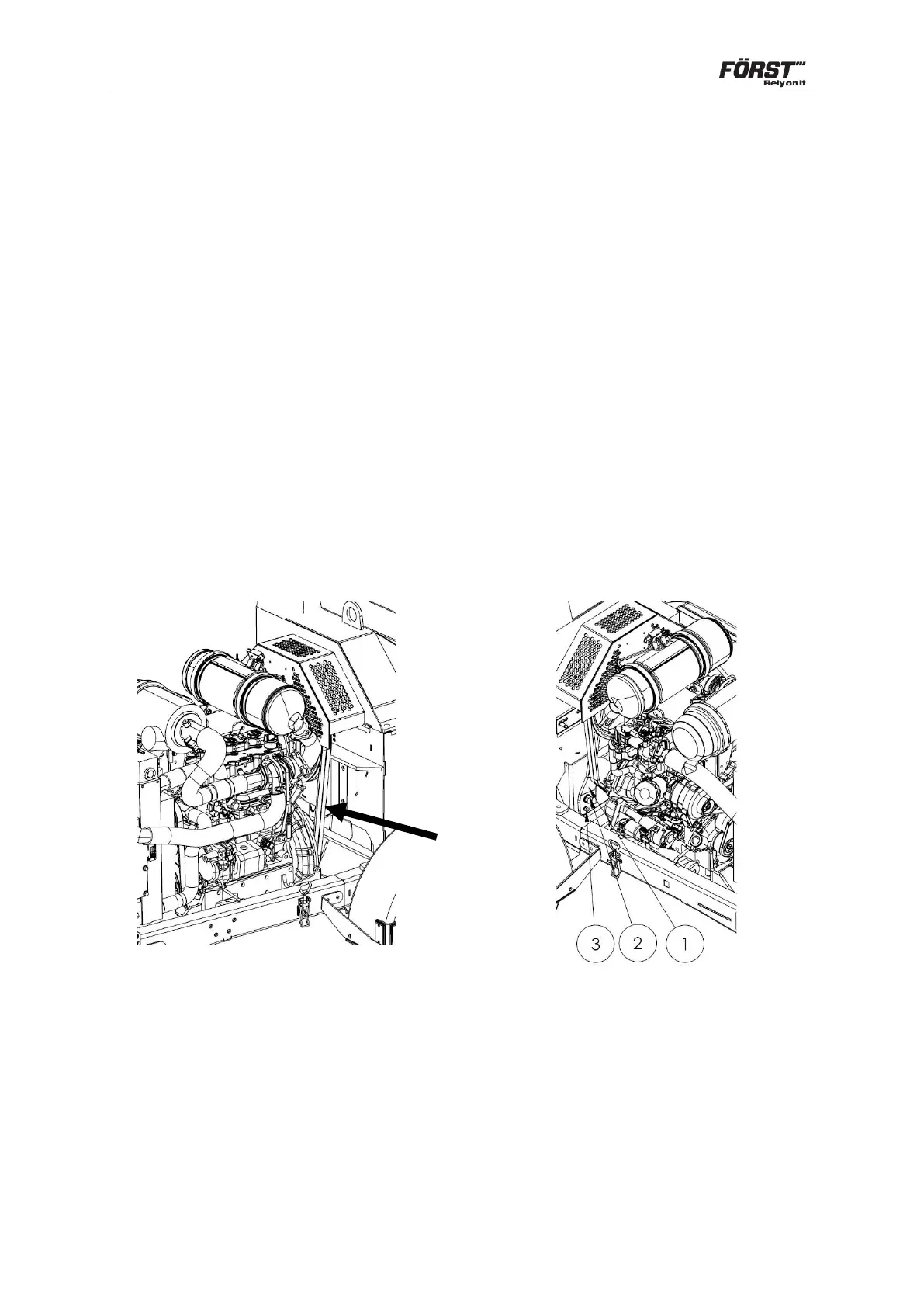

All drive belts are located under the engine cover. Tension checked at arrow shown

below. Check and set tension as follows:

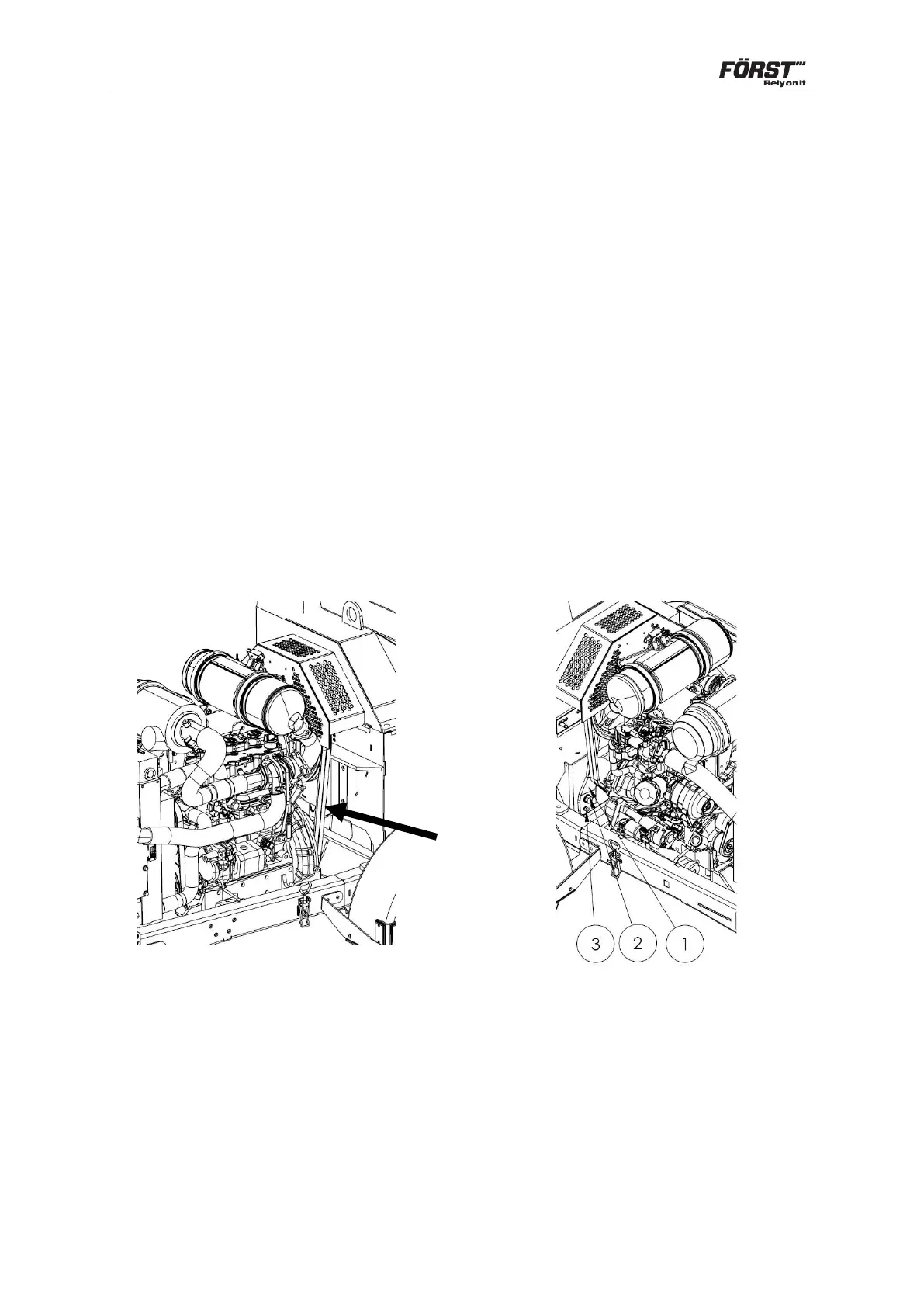

1. Slacken tensioner securing screws (2, 3)

2. Pull the tensioner assembly out to increase the tension (1)

3. For the correct tension, the belt should deflect by 6mm when 4.5kg of force is

applied at the centre of the longest span shown by the arrow. This can be

approximated by firmly gripping belt between finger and thumb and twisting.

The belt should not be able to be rotated more than 90°.

4. Tighten both screws (2, 3)

5. Run machine and test.

6. Check belt tension

Loading...

Loading...